Enhanced TDS

Identification & Functionality

- CASE Ingredients Functions

- Chemical Family

- Function

- Accelerator,Curing Agent

- Industrial Additives Functions

- Technologies

- Product Families

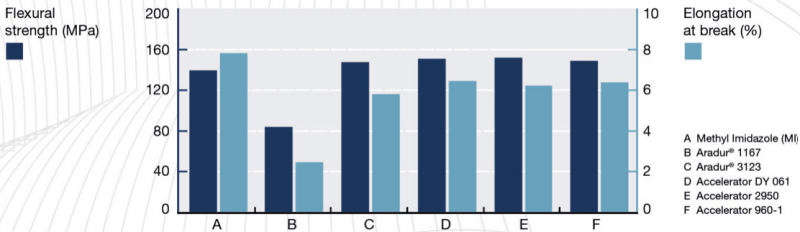

- Chemical Structure

Features & Benefits

- CASE Ingredients Features

- Advantages

Shortens dust-dry time and full-cure time. To avoid impairment of the mechanical and chemical properties of ARALDITE® systems, the quantity of ACCELERATOR 960-1 added should not exceed 2%, relative to the epoxy resin.If greater quantities are added, the proportion of hardener must be reduced.

Applications & Uses

- Coating End Applications

- Compatible Polymers & Resins

- Application Details

ACCELERATOR for polyamines, polyamidoamines and their adducts used in conjunction with ARALDITE® epoxy resins for the formulation of ambient cure systems.

Properties

- Physical Form

- Soluble In

Regulatory & Compliance

Technical Details & Test Data

- Accelerators for Anhydride Hardeners

Product Latency / reactivity Impact on mechanical properties Form/processability Reference Methyl Imidazole (MI) Very fast High Tg Standard modulus Liquid (~ 40mpa.S) Accelerator 2950 Almost equivalent to reference Higher modulus medium Tg Liquid (~ 4000 mpa.S) Kinetics

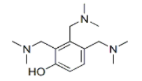

Viscosity build-up, time to reach 1 000 Pa.s

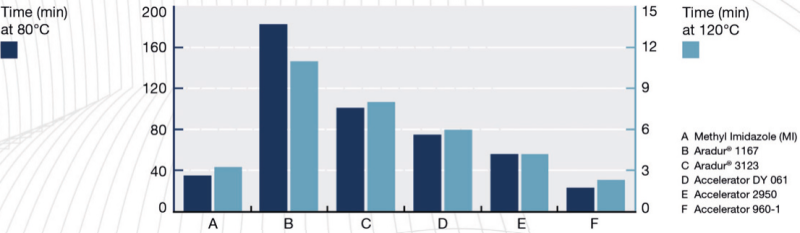

Thermo-mechanical properties

Modulus and Tg

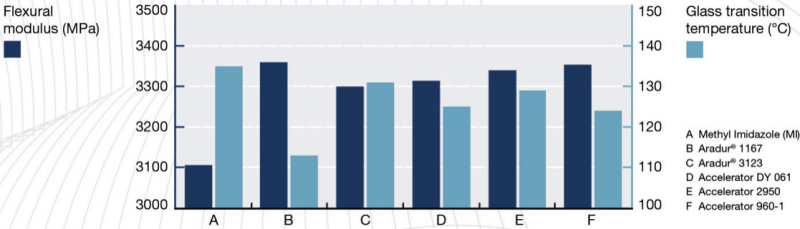

Mechanical properties

Elongation at break and flexural strength

Note: Detailed information about Accelerators for dicyandiamide hardeners & Accelerators for amine cure from RT to 60°C can be accessed through this link.

- Drying and Gel Time

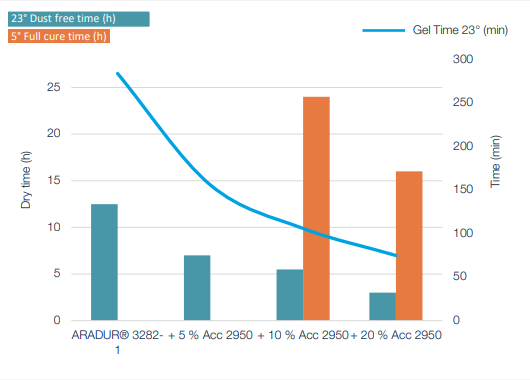

ACCELERATOR 960-1 offers at room temperature a good balance between faster drying time and reduction of gel time as well as a low viscosity.

Gel time measured with Araldite® GZ 280X80 mixed at stoichiometry in 100 g at 23°C;

Dry time measured with Araldite® GZ 280X80 mixed at stoichiometry on a thin film.- Test Data

Accelerators for amine cure from RT to 60°C

Accelerators Reactivity at room temperature Reactivity at 60°C Processability Ethylamine-boron Trifluoride (Reference) Reference Reference Solid (Softening point: 88°C) Accelerator 960-1 1.8 times more stable than reference Medium

acceleration

1.5 more stable than referenceLiquid (~ 225 mPa.s)

Safety & Health

- Safety Precautions

- Do not get in eyes, on skin or clothing.

- Do not inhale mist or vapors.

- Keep container tightly closed when not in use and during transport.

- Wash after handling.

- First Aid

- Eyes: Immediately flush with water for at least 15 minutes. Get immediate medical attention.

- Skin: Promptly wash thoroughly with mild soap and water.

- Inhalation: Remove to fresh air. Give oxygen if breathing is difficult.

- Ingestion: If conscious, give plenty of water. Get immediate medical attention.

Packaging & Availability

- Regional Availability

Storage & Handling

- Storage Information

ACCELERATOR 960-1 is supplied in 440 pound steel drums. The product has a shelf life of two years when stored at room temperature in the original sealed container.

Other

- Appearance

- Clear, brown liquid

- Color (SDS)

- Light yellow

- Odor (SDS)

- Ammoniacal

- Application Information

Value Units Test Method / Conditions Mix Ratio 0.5-10.0 g/100g g/100g - Chemical Properties

Value Units Test Method / Conditions Amine Value 561.0-673.0 mg KOH/g mg KOH/g - Physical Properties

Value Units Test Method / Conditions Density 0.97 g/cm³ g/cm³ At 25°C Flash Point 254.0 °C °C Closed Cup Viscosity 150.0-300.0 mPa.s mPa.s At 25°C