Enhanced TDS

Identification & Functionality

- Base Chemicals Functions

- Blend

- No

- CAS Number

- 68909-77-3

- Chemical Family

- Function

- Intermediate

- Single Ingredient

- Yes

- Technologies

- Product Families

Applications & Uses

- Applicable Processes

- Base Chemicals End Uses

- Markets

- Applications

- Application Information

Intermediate in the preparation of emulsifiers, emulsion breakers, surfactants, and cement additives.

Properties

- Physical Form

Regulatory & Compliance

- Chemical Inventories

Technical Details & Test Data

- Chemical Constituents

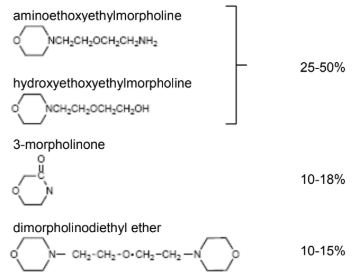

Gas chromatographic analysis of Amine C-400 shows the major components to be:

These constituents represent approximately two-thirds of the Amine C-400. Of the remainder, some of the components have been identified and some have not. Those which have been identified as present in small quantities are:

- bis-(2-aminoethyl) ether

- 4-(2-aminoethyl) morpholine

- 2-(2-aminoethoxy) ethanol

- dimorpholinoethane

- diethylene glycol

Packaging & Availability

- Packaging Type

- Availability

Amine C-400 is currently available in bulk only.

Storage & Handling

- Handling and Storage Information

Carbon steel is a satisfactory material for storing and handling Amine C-400. Copper, zinc, lead, or alloys containing any of these materials should not be used since they will be attacked by the product. Mild steel is acceptable for transfer lines. Since the product will leach conventional pipe dopes from threaded connections, the lines should be welded or flanged. Satisfactory gasketing materials are Garlock 7021, U.S. Rubber 899, John Crane 333, Johns-Manville 70, or equivalent.

Centrifugal pumps constructed of carbon steel or black iron are satisfactory. Either pump packing or a mechanical seal may be used. Braided TEFLON® fluoropolymer and polypropylene are satisfactory packing materials. Seals may be John Crane Type 9, Durametallic Type RO-TT, or equivalent with either stellite and carbon or tungsten faces and TEFLON® fluoropolymer V-rings.

- Storage Information

Carbon steel is a satisfactory material for storing and handling Amine C-400. Copper, zinc, lead, or alloys containing any of these materials should not be used since they will be attacked by the product.

Mild steel is acceptable for transfer lines. Since the product will leach conventional pipe dopes from threaded connections, the lines should be welded or flanged. Satisfactory gasketing materials are Garlock 7021, U.S. Rubber 899, John Crane 333, Johns-Manville 70, or equivalent.Centrifugal pumps constructed of carbon steel or black iron are satisfactory. Either pump packing or a mechanical seal may be used. Braided TEFLON® fluoropolymer and polypropylene are satisfactory packing materials. Seals may be John Crane Type 9, Durametallic Type RO-TT, or equivalent with either stellite and carbon or tungsten faces and TEFLON® fluoropolymer V-rings.

Other

- Odor

- Ammonia-like

- Oxidizing Properties (SDS)

- None

- Chemical Properties

Value Units Test Method / Conditions Amine Value 5.4-6.5 meq/g meq/g Amine Value 4.6-9.0 meq/g meq/g ST-31.41, A Equivalent Weight max. 213.0 kg/eq kg/eq ST-31.41, A pH min. 11.0 - ST-31.36, A 1:1 dilution - Physical Properties

Value Units Test Method / Conditions Boiling Point 249.0 °C °C Flash Point 152.0 °C °C Pensky-Martens Closed Cup (PMCC) Specific Gravity 1.09 - Viscosity 100.0-300.0 cSt cSt