Enhanced TDS

Identification & Functionality

- CASE Ingredients Functions

- Chemical Family

- Function

- Curing Agent

- Technologies

- Product Families

Features & Benefits

- CASE Ingredients Features

- Labeling Claims

- Materials Features

- Product Features

Surface Technologies formulated with ARADUR® 2965-1 exhibit:

- Outstanding cure and short dust-dry time, even at temperatures down to 10/15 °C and high relative humidity

- Low viscosity, easy processing

- Good mechanical properties

- Good overall chemical resistance

- Smooth, glossy, tack-free films

Applications & Uses

- Coating End Applications

- Plastics & Elastomers End Uses

- Markets

- Applications

- Application Details

- mortars and floor repair systems

- sewage treatment plants

- commercial and industrial flooring

- Application Information

With liquid epoxy resins - bisphenol-A resins as ARALDITE® GY 250, GY 253, GY 257 or GY 266, bisphenol-F resins as ARALDITE® GY 281 or bisphenol-A/F resins as A ARALDITE® PY 302-2 and GY 783 for solvent-free coatings for heavy-duty corrosion protection and floorings.

Properties

- Physical Form

Regulatory & Compliance

Technical Details & Test Data

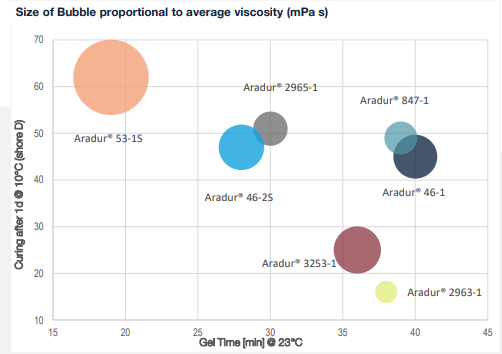

- Gel Time, Curing Speed and Viscosity

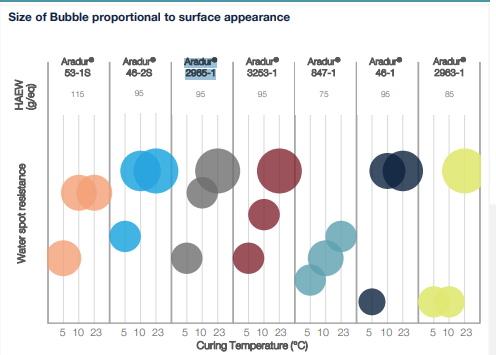

- Surface appearance and Water-spot on Thin Film

Packaging & Availability

- Regional Availability

Storage & Handling

- Storage Information

ARADUR® 2965-1 should be stored in a dry place, preferably in the sealed original container, at temperatures between 2 and 40 °C. The product should not be stored exposed to direct sunlight. Shelf life (at storage temperature between 2 - 40 °C) (see expiry date on original container) - 3 years at least

Other

- Appearance

- Clear liquid

- Color (SDS)

- Yellow

- Odor

- Amine

- Application Information

Value Units Test Method / Conditions Mix Ratio 50.0 g/100g g/100g - Chemical Properties

Value Units Test Method / Conditions Amine Value 330.0-360.0 mg KOH/g mg KOH/g ISO 9702 - Physical Properties

Value Units Test Method / Conditions Density 1.05 g/cm³ g/cm³ ISO 1675 at 20°C Flash Point min. 117.0 °C °C Pensky-Martens Closed Cup (PMCC) Flash Point min. 117.0 °C °C ISO 2719 Gel Time 32.0 m m at 23°C, 100g Viscosity 80.0-250.0 cPs cPs Falling Ball Viscometer at 25°C Viscosity 80.0-250.0 cPs cPs ISO 12058-1 at 25°C