Enhanced TDS

Identification & Functionality

- CASE Ingredients Functions

- Chemical Family

- Function

- Hardener,Crosslinking Agent

- Industrial Additives Functions

- Technologies

- Product Families

Features & Benefits

- CASE Ingredients Features

- Industrial Additives Features

- Labeling Claims

- Key Properties

Used along with suitable epoxy resins, ARADUR® 75-1 presents the following features:

- Bisphenol A and Nonylphenol free

- A high degree of flexibility; setting at temperatures in the region of -10 °C

- Satisfactory mechanical properties along with Araldite® GY 783 , GY 784 ; where unmodified resins such as Araldite® GY 250 are used, even higher degrees of stability are possible, however with a reduction in flexibility

- Good adhesion to dry concrete and sand-blasted steel

- The possibility of formulating extremely low-solvent binder systems.

ARADUR® 75-1 provides a higher degree of stability than ARADUR® 70 when exposed to heat.

Applications & Uses

- Coating End Applications

- Industrial Additives End Use

- Application Information

In combination with liquid epoxy resins such as Araldite® GY 250, GY 783 and GY 784, ARADUR® 75-1 is suitable for the production of viscoelastic binder systems, impact-elastic coatings, crack-covering membranes and liquid foils for sealing purposes.

Properties

- Physical Form

- Mix Ratio

The optimum mix ratio for Araldite® GY 783 Huntsman Advanced Materials and ARADUR® 75-1 is 100:129 parts by weight

Regulatory & Compliance

- Chemical Inventories

Technical Details & Test Data

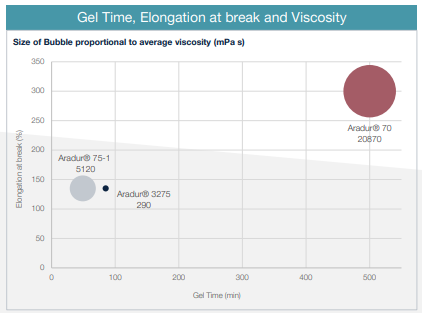

- Gel Time, Elongation at break and Viscosity Graph

Packaging & Availability

- Regional Availability

Storage & Handling

- Handling Precautions

Mandatory and recommended industrial hygiene procedures should be followed whenever our products are being handled and processed.

- Storage Information

ARADUR® 75-1 should be stored in a dry place, preferably in the sealed original container, at temperatures between 2 and 40°C. The product should not be stored exposed to direct sunlight.

Other

- Appearance

- Clear liquid

- Color (SDS)

- Yellow

- Odor

- Amine / methyl isobutyl ketone

- Chemical Properties

Value Units Test Method / Conditions Amine Value 120.0-140.0 mg KOH/g mg KOH/g ISO 9702 - Physical Properties

Value Units Test Method / Conditions Density 0.97 g/cm³ g/cm³ ISO 1675 at 20°C Flash Point 95.0 °C °C Pensky-Martens Closed Cup (PMCC) Flash Point 95.0 °C °C ISO 2719 Gel Time 40.0 m m Tecam Gelation Timer at 23°C, 250g with Araldite® GY 250 Gel Time 58.0 m m Tecam Gelation Timer at 23°C, 250g with Araldite® GY 783 Glass Transition Temperature (Tg) max. -10.0 °C °C Cured with ARALDITE® GY 250 Viscosity 3000.0-9000.0 mPa.s mPa.s ISO 3219 at 25°C Viscosity 3000.0-9000.0 mPa.s mPa.s Rotational Viscometer at 25°C