Enhanced TDS

Identification & Functionality

- Chemical Family

- RTU Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Features and Benefits

- Retain good clarity & light transmission at elevated temperature

- Exhibit good crack resistance

- Adhere to leadframe and housing firmly

Applications & Uses

- Composites Processing Methods

- Product End Uses

- System Preparation

- Pre-Mixing: Component A to be preheated at 60°C/30min

- Mixing: The mixture of component A/component B may be mixed using standard techniques.

- Degassing: Use vacuum device; 0 - 10 mmHg

- Application Information

- Applicable for blue and white LED

- Applicable for chip and high power LED

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Typical Cured Information

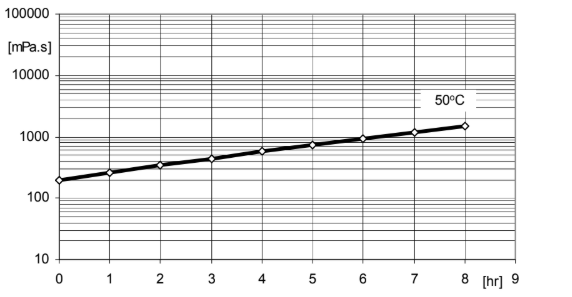

Fig 1: Viscosity increment at 50⁰C

Initial viscosity : BH type Viscometer at 25°C : 2600 mPa.s

20 rpm at 50°C : 150 mPa.sRecommended cure schedule

1st Step Cure at 130°C : 1 hour

Post Cure at 150°C : 5 hoursNote: Actual oven cure is dependent upon applications and substrate/component design.

Specimen cured at 130°C for 1 hr and 150°C for 5 hr

Property Test Method Test Values Unit At Condition Glass Transition Temperature (Tg) DSC 127 °C - Hardness (Shore D) ASTM D-2240 90 - - Flexural Strength ASTM D-790 15.8 kg/mm² 25°C Flexural Modulus ASTM D-790 275 kg/mm² 25°C Thermal Expansion - 50 ppm Below Tg Thermal Expansion

166 ppm Above Tg Volume Resistivity ASTM D257 8.7 x 10¹⁵ Ω·cm - Dielectric Constant ASTM D150 3.15 - 1 MHz Dielectric Loss ASTM D150 1.7 % 1 MHz

Safety & Health

- Industrial Hygiene

Mandatory and recommended industrial hygiene procedures should be followed whenever our products are being handled and processed.

Storage & Handling

- Storage Conditions

- The components have to be stored under dry conditions below 25°C, in tightly sealed original containers. Under these conditions, the shelf life will correspond to the expiry date stated on the label. After this date, the product may be processed only following reanalysis. Partly emptied containers should be closed tightly immediately after use.

- Disposal - Regular procedures approved by national and/or local authorities

Other

- Application Information

Value Units Test Method / Conditions Mix Ratio 1.05 %(W) %(W) Hardener : Resin