Enhanced TDS

Identification & Functionality

- Chemical Family

- RTU Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Features and Benefits

- Low density two-part Epoxy Void and Edge Filler

- Self extinguishing

- Non sagging paste

- High compression resistance

- Easily sandable

- 24 months shelf life

- High Temperature stability after room temperature cure

Applications & Uses

- Application Area

- Composites Processing Methods

- Markets

- Applications

- Processing Information

Mix ratio Parts by weight Parts by volume Araldite® 252-1 Resin 100 100 Hardener 252-2 30 40 Recommended cure cycle:

7 days at 23°C or 2 hours at 70°CHandling strength:

16 hours at 23°CApplication:

The resin and hardener must be blended until they form a homogeneous mix shown by a uniform color. The mix can be applied manually or extruded.The pot life depends on the quantity mixed and the shape of the container (use a shallow container to extend pot life). As an approximate guide:

For a 50g mix, pot life at 23°C is 2 hours

For a 100g mix, pot life at 23°C is 1,5 hoursEquipment maintenance:

All tools should be cleaned before syntactic residues have had time to cure. The removal of cured residues is a difficult and time-consuming operation. If solvents such as acetone are used for cleaning, operatives should take the appropriate precautions and, in addition, avoid skin and eye contact.

Properties

- Physical Form

Regulatory & Compliance

- OEM Specifications

- Quality Standards

Technical Details & Test Data

- Typical Cured Information

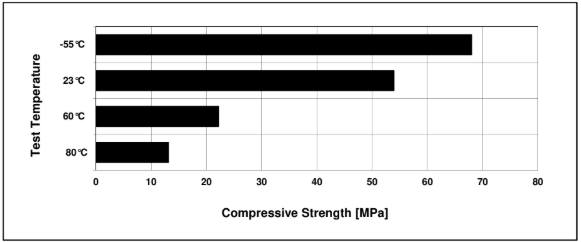

Compressive strength (typical average values) – Cure 2h at 70°C

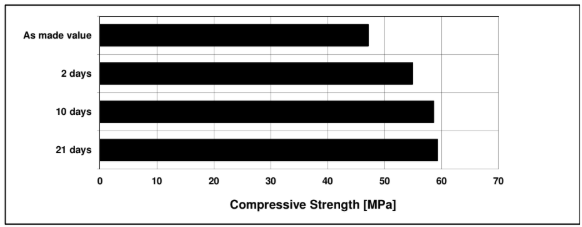

Compressive strength versus 80°C heat ageing (typical average values)

Cure 7 days at RT

Test at 23°C

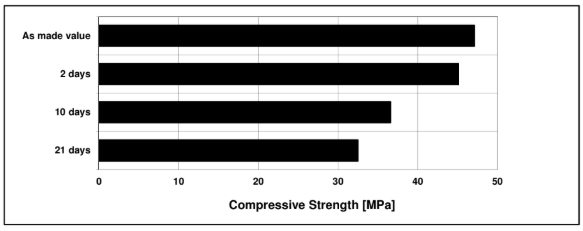

Compressive strength versus tropical weathering ageing (40°C / 92% RH)

(typical average values)

Cure 7 days at RT

Test at 23°C

Compressive Modulus at 23°C (typical average values):

cure 2h at 70°C: 2.6 GPa

cure 7 days at 23°C: 2.4 GPaAverage lap shear strength (typical average value) : 12 MPa

Substrate: Sand blasted aluminium (ISO 4587)

Cure 2h at 70°C - Test at 23°CFlammability - Vertical Bunsen Burner Test (typical average values)

Cure cycle: 7 days at 23°CTest method Standard Test Requirements Results 12s Ignition Time AITM 2-0002B Burning time ≤ 15 s 0 Drip burning time ≤ 5 s 0 Burn length ≤ 203 mm 2 60s Ignition Time

AITM 2-0002A Burning time ≤ 15 s 1 Drip burning time ≤ 3 s 0 Burn length ≤ 152 mm 80 Maximum optical smoke density (typical average values)

Cure cycle: 7 days at 23°CTest method Test method Requirements Results (sample thickness = 2 mm)

Non flaming mode Non flaming mode Dm < 200 75 Flaming mode Flaming mode Dm < 200 164 Concentration of smoke gas (typical average values)

Cure cycle: 7 days at 23°CTest method Standard Gas Requirements Results Non flaming mode AITM 3-0005 CO Max 1000 ppm 8 SO₂ Max 100 ppm 0 NOX Max 100 ppm 1 HF Max 100 ppm 0 HCl Max 150 ppm 0 HCN Max 150 ppm 0 Flaming mode AITM 3-0005 CO Max 1000 ppm 199 SO₂ Max 100 ppm 7 NOX Max 100 ppm 13 HF Max 100 ppm 0 HCl Max 150 ppm 0 HCN Max 150 ppm 10

Storage & Handling

- Storage and Handling Information

- Araldite® 252-1 resin and Hardener 252-2 can be stored for up to 2 years at (6 - 28)°C in their original sealed containers. The expiry date is indicated on the label.

- Our products are generally quite harmless to handle provided that certain precautions normally taken when handling chemicals are observed. The uncured materials must not, for instance, be allowed to come into contact with foodstuffs or food utensils, and measures should be taken to prevent the uncured materials from coming in contact with the skin, since people with particularly sensitive skin may be affected. The wearing of impervious rubber or plastic gloves will normally be necessary; likewise the use of eye protection. The skin should be thoroughly cleansed at the end of each working period by washing with soap and warm water. The use of solvents is to be avoided. Disposable paper - not cloth towels - should be used to dry the skin. Adequate ventilation of the working area is recommended.

Other

- Application Information

Value Units Test Method / Conditions Mix Ratio 0.3 %(W) %(W) Hardener : Resin - Physical Properties

Value Units Test Method / Conditions Density max. 0.77 g/cm³ g/cm³ Internal Method Gel Time 120.0-300.0 m m Internal Method at 25°C