Enhanced TDS

Identification & Functionality

- Chemical Family

- RTU Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Product Features

- Flexible castings

- Excellent dielectric properties vs Temperature.

- Good thermal shock resistance.

- Self extinguishing UL 94 V-0 (4 mm).

Applications & Uses

- Composites Processing Methods

- Product End Uses

- Processing Methods

Casting / vacuum casting / oven curing.

- Application Information

- Transformers

- Pressure sensitive devices

- Inductance coils with ferrite cores

- Processing Information

Preparation

- ARALDITE® CW 1491 and XW 1257-1 contain fillers, which tend to settle over time. It is therefore recommended to carefully homogenize the complete contents of the container before use.

- In the storage vessels of the production equipment, the pre-filled products should be stirred up from time to time to avoid sedimentation and irregular metering.

Mixing

- To facilitate stirring and removal, highly filled components are heated to 60 - 80°C in the original container (e.g. overnight in an oven).

- To prepare the casting mix the resin component should be homogenized in holding tank A at 60 - 80°C under a vacuum of 1 - 5 mbar, the hardener component in holding tank B at 25 - 60°C and a vacuum of 1 - 5 mbar.

Curing

- Determine whether cross-linking has been carried to completion and the final properties are optimal, it is necessary to carry out relevant measurements on the actual object or to measure the glass transition temperature.

- Different gel and cure cycles in the customer’s manufacturing process could lead to a different degree of cross-linking and thus a different glass transition temperature.

Properties

- Flame Rating

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

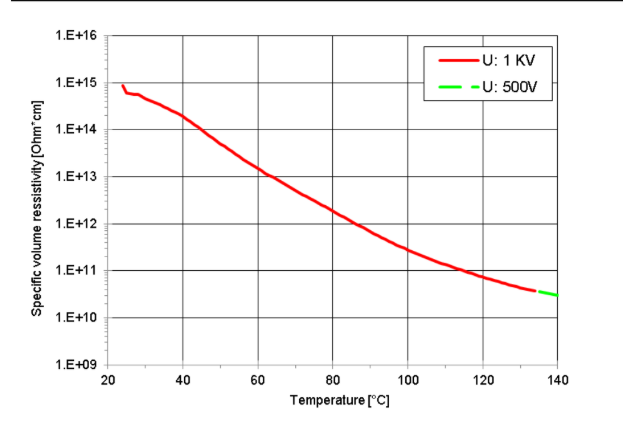

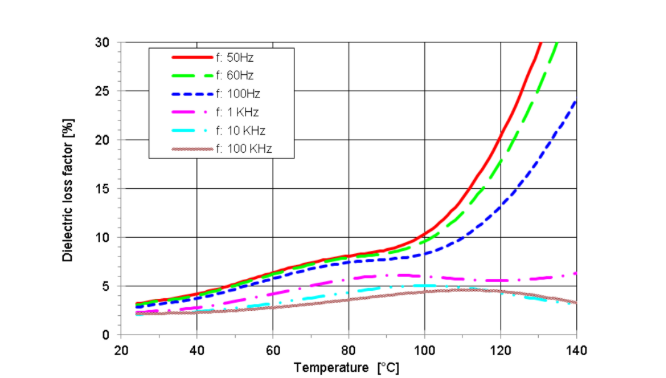

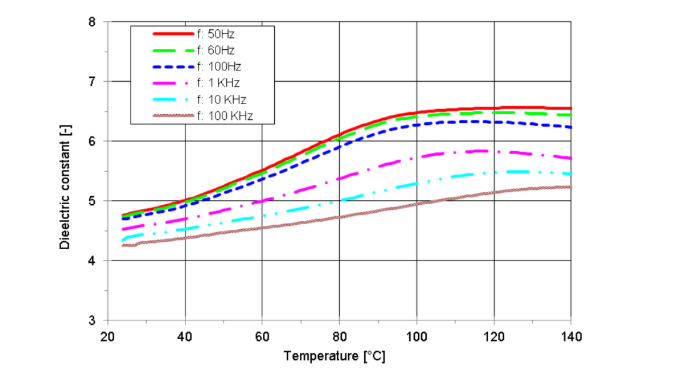

- Electrical Properties

Condition : Cured for 3h/80°C + 4h/100°C.

Property Value Unit Test method Dielectric Constant (50Hz, 25°C) 3.2 IEC 60250 Dielectric Loss Factor (tan δ, 50Hz, 25°C) 4.8 % IEC 60250 Dielectric Strength (3 mm specimen) 23 kV/mm IEC 60243-1 Tracking Resistance min. 600 Grade IEC 60112 Volume Resistivity (25°C) 6 x 10¹⁴ Ω·cm DIN EN 60093

Fig. 4.1: Specific volume resistivity f(T) – IEC 60093

Fig. 5.1: Dielectric loss factor tanδ f(T) – IEC 60250

Fig. 5.2: Dielectric constant εR f(T) – IEC 60250

- Mechanical & Physical Properties

Condition : Cured for 3h/80°C + 4h/100°C.

Property Value Unit Test method Color of Castings Blue - - Elongation at break 13 % ISO 527 Flammability V-0 - UL 94 Glass Transition Temperature 32 °C ISO 11357-2 Hardness 65 Shore D DIN 53505 Specific Gravity 1.64 g/cm³ DIN 55990 Tensile Modulus 560 MPa ISO 527 Tensile Strength 13 MPa ISO 527 Thermal Conductivity 0.72 W/mK ISO 8894-1

Storage & Handling

- Storage Conditions

- Store the components in a dry place according to the storage conditions stated on the label in tightly sealed original containers.

- Under these conditions, the shelf life will correspond to the expiry date stated on the label.

- After this date, the product may be processed only after reanalysis.

- Partly emptied containers should be tightly closed immediately after use.

Other

- Application Information

Value Units Test Method / Conditions Mix Ratio 0.8 %(W) %(W) Hardener : Resin