Enhanced TDS

Identification & Functionality

- Chemical Family

- RTU Product Type

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Ready-to-Use Product Features

- Product Features

- Excellent thermal aging behaviour

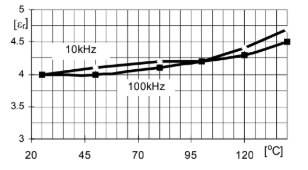

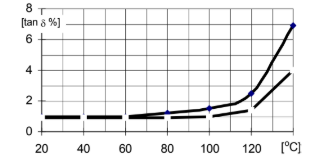

- Good dielectric properties

- Good mechanical properties

- Good thermal shock resistance

- Flammability: UL 94 approval (V-0 for 6 mm thick layer)

Applications & Uses

- Composites Processing Methods

- Product End Uses

- Application Information

- High voltage TV components like Fly Back Transformers (FBT)

- Diode Split Transformers (DST)

- Processing Methods

Vacuum casting

- System Preparation

- The filled ARALDITE resin component should be stirred and homogenized in the original containers before use.

- To facilitate stirring and removal, filled components are heated to 60-80°C in the container (e.g. overnight in an oven).

- To prepare the casting mix the resin should be homogenized in holding tank A at 65- 80°C under a vacuum of 1-5mbar, the hardener in holding tank B at 25-45°C and a vacuum of 1-5 mbar. The preparation time depends on the quantity and preparation parameters. A metering unit should be used to feed the ARALDITE resin and the ARADUR hardener to an impeller mixer.

Properties

- Flame Rating

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

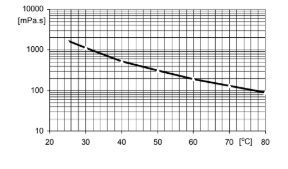

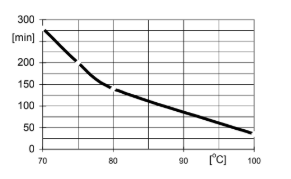

- Processing Viscosity

Fig 1: Initial viscosity versus temperature (ISO 9371, Hoeppler)

Fig 2: Geltime versus temperature (ISO 9396, Gelnorm)

- Mechanical & Physical Properties

Mechanical and Physical Properties:

cured for 1h at 70°C + 2h at 80°C + 2h at 110°C

Property Value Unit Test Method Color of castings White - - Density 1.55 g/ml DIN 55990 Shore D hardness 90 Shore D DIN 53505 Glass transition temperature 110 °C ASTM E1356 Flexural strength 80 MPa ISO 178 Elongation at break (Flexural) 1.3 % ISO 178 Flexural modulus 6600 MPa ISO 178 Tensile strength 60 MPa ISO 527 Elongation at break (Tensile) 1.2 % ISO 527 Flexural modulus (Tensile) 6700 MPa ISO 527 Impact strength 6 kJ/m² ISO 179 Water absorption, 1 day at 25°C 0.06 % ISO 62 Water absorption, 30 min at 100°C 0.10 % ISO 62 Coefficient of linear thermal expansion (20 - 80°C) 46 x 10⁻⁶ K⁻¹ DIN 53752 Thermal conductivity 0.53 W/m·K DIN 8894/90 Flammability V-O (6 mm) - UL 94 Fig 3: Dielectric constant εr versus temperature (IEC 250)

Fig 4: Dissipation factor tan % versus temperature (IEC 250)

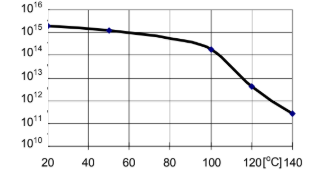

Fig 5: Volume resistivity ρ [Ω cm] versus temperature (IEC 93)

- Electrical Properties

cured for 1h at 70°C + 2h at 80°C + 2h at 110°C

Dielectric strength (at 25°C) 31 kV/mm IEC 243-1 Dielectric strength (at 80°C) 29 kV/mm IEC 243-1 Dielectric strength (at 130°C) 47 kV/mm IEC 243-1 Tracking resistance (CTI) > 600 IEC 112

Storage & Handling

- Storage Conditions

- Prefilled, liquid products always show small filler sedimentation.

- Before partial use we recommend to stir up carefully the components or to use each container as complete unity.

- Store the components in a dry place at 18-25°C, in tightly sealed original containers.

- Under these conditions, the shelf life will correspond to the expiry date stated on the label.

- After this date, the product may be processed only after reanalysis.

- Partly emptied containers should be tightly closed immediately after use.

Other

- Application Information

Value Units Test Method / Conditions Mix Ratio 0.32 %(W) %(W) Hardener : Resin