Enhanced TDS

Identification & Functionality

- Chemical Family

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Product Features

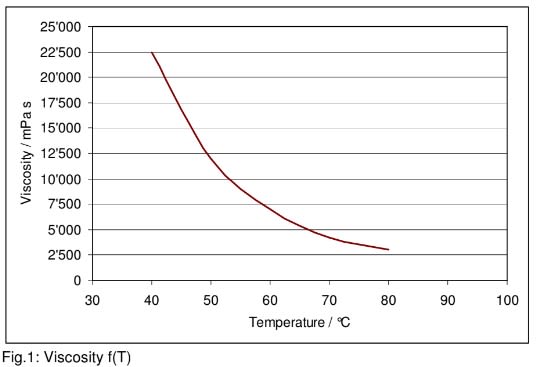

- 1-c epoxy system with deep viscosity drop above 60°C for fast processing

- Very high endurance

- Excellent resistance to atmospheric and chemical degradation.

- Key Properties

- Very high thermal conductivity.

- Single component resin (self-reactive).

- High operating temperature.

Applications & Uses

- Applicable Processes

- Composites Processing Methods

- Industrial Additives End Use

- Processing Methods

- Vacuum / Atmospheric Pressure Casting

- Vacuum Automated Pressure Gelation

- Product Applications

- Potting of motors, generators, actuators, modules and sensors.

Properties

- Physical Form

Regulatory & Compliance

- Chemical Inventories

Technical Details & Test Data

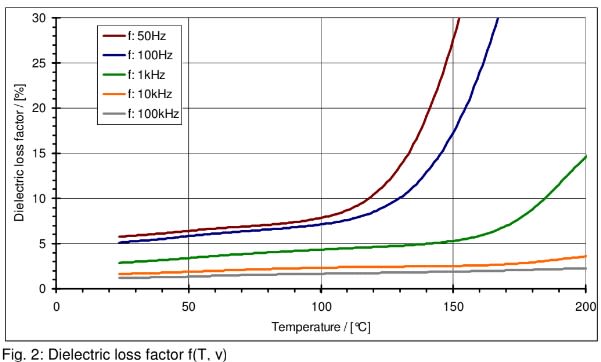

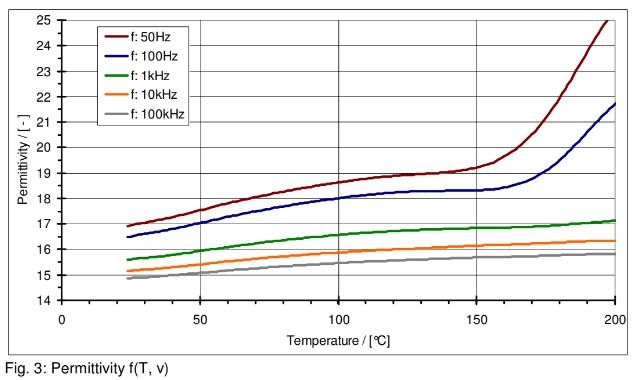

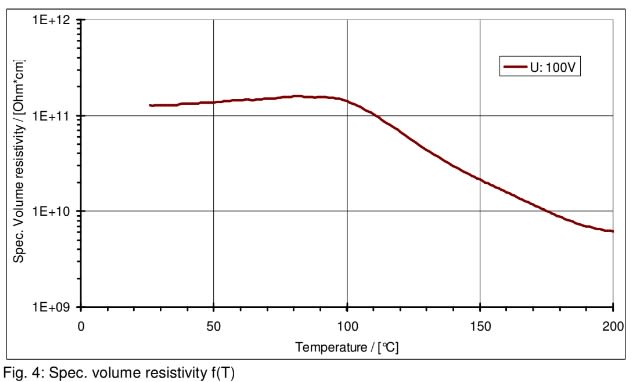

- Technical Graphs

- Processing Information

Important instructions for safe handling and processing

- ARALDITE® CW 2731 is a single component self-reactive material which should be stirred if the temperature exceeds 40°C. Without stirring the thermoset can start to react and can cause hot spots. These hot spots can further accelerate the reaction. It will cause especially for bigger volumes a runaway reaction and thermal decomposition of the thermoset with high heat and heavy smoke development.

- Recommended maximum time at temperature with stirring: 80°C/1h, 70°C/3h, 60°C/9h, 50°C/12 h, 40°C/96h.

- If the material has a temperature > 40°C and processing is paused or interrupted the material must be cooled down under slight stirring. It is important that the agitator allows a sufficient homogenous blending with low power to avoid temperature increase. This stirring prevents the creation of hot spots in the material which could lead to a viscosity increase or in worst case to the already above mentioned runaway reaction.

Preparation

- ARALDITE® CW 2731 contains fillers, which tend to settle over time. It is therefore recommended to homogenize the complete contents of the container before use. The use of ceramic materials is recommended, due to the abrasiveness of the filler.

- The material should be stirred with high speed at 40-80°C (s. warning below) for approx. 10-20 min and homogenized in the original container before use. After the sediment is homogenized stir for about 2 hrs at a lower speed. This lower speed should allow to stir the material without increasing the temperature.

- If not homogenized under vacuum a lot of air bubbles will be entrapped in the material! These air bubbles have an influence on the thermal conductivity and the electric properties. This means that the material which is homogenized under atmospheric pressure must be afterwards evacuated to remove all air bubbles.

Processing

Potting: Resin 50-60°C.

- Part preheating recommended. Temperature depends on gap width. Deep small gaps need lower pre- heat temperature (70-100°C) to avoid curing before voids have reached the surface. Curing cycle: 1 h/ 180°C. For reduced internal stess: 1h/ 120°C + 45 min/ 180°C.

APG:

- Resin 50-60°C.

- Mold 130-140°C.

- Cycle time can be 30-50% shorter than standard systems.

- Curing depends on part (e.g. 8h/ 150°C).

Curing

- To determine whether cross-linking has been carried to completion and the final properties are optimal, it is necessary to carry out relevant measurements on the actual object or to measure the glass transition temperature. Different gel and cure cycles in the customer’s manufacturing process could lead to a different degree of cross- linking and thus a different glass transition temperature.

Packaging & Availability

- Regional Availability

Other

- Appearance

- Greyish paste

- Color (SDS)

- Grey Red

- Odor (SDS)

- Slight

- Mechanical Properties

Value Units Test Method / Conditions Flexural Strength1 80.0 MPa MPa ISO 178 at 23°C Hardness2 92.0 Shore D Shore D DIN 53505 at 23°C - Physical Properties

Value Units Test Method / Conditions Density1 2.6 g/cm³ g/cm³ ISO 1183 at 23°C Glass Transition Temperature (Tg)2 165.0 °C °C ISO 11359-2 Specific Gravity 2.6 - ISO 2811 at 25°C Viscosity 5000.0-20000.0 mPa.s mPa.s ISO 3219 at 50°C - Thermal Properties

Value Units Test Method / Conditions Specific Heat1 1.0 J/g.K J/g.K ISO 11357-4 at 25°C Thermal Conductivity2 3.0 W/m·K W/m·K ISO 8894-1 at 23°C