Enhanced TDS

Identification & Functionality

- Chemical Family

- Fillers Included

- RTU Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

Applications & Uses

- Composites Processing Methods

- Product End Uses

- Processing Information

Because of the tendency to sedimentation of the filler,filled components in principle require stirring before removal from the original containers. To avoid errors in dosage this step is especially important when removing only part of the contents. To facilitate stirring and removal, highly-filled components are heated to 60-80°C in the original container (e.g. overnight in an oven).

To prepare the casting mix the resin component should be homogenized in holding tank A at 80-90°C under a vacuum of 1-5 mbar, the hardener component in holding tank B at 30- 40°C and a vacuum of 1-5 mbar. A metering unit should be used to feed the resin and hardener components to an impeller mixer.

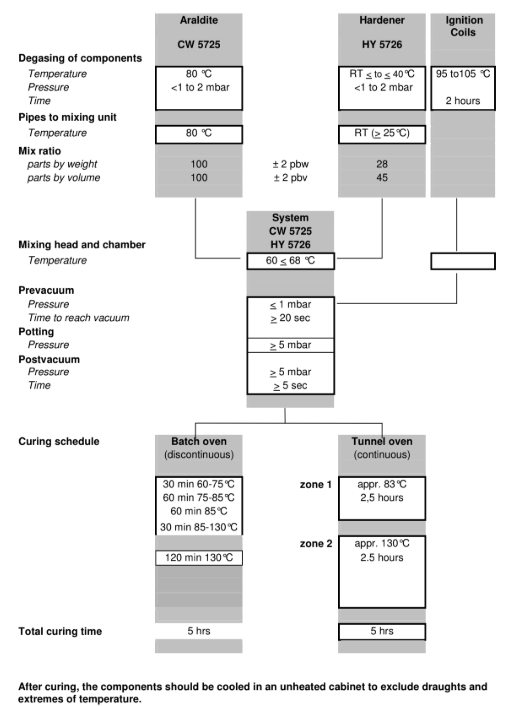

Recommended guidelines (depending on equipment used)

Properties

- Physical Form

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Properties

- Very good thermal shock resistance

- Very good thermal endurance

- Minimum Curing Time

2.5 hours at 90°C + 2.5 hours at 130°C

- Electrical Properties

Property

Test Method

Unit

Value

Dielectric strength (on 2 mm plate at 23°C)

IEC 60243-1

kV/mm

25

Dielectric strength (on 1 mm plate at 23°C)

IEC 60243-1

kV/mm

41

Tracking resistance (with test solution A)

IEC 60112

-

CTI > 600

Tracking resistance (with test solution B)

IEC 60112

-

CTI > 600

Electrolytic corrosion

IEC 60426

-

A-1

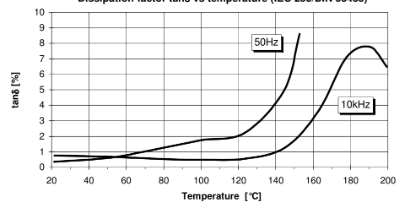

Dissipation factor tanδ vs temperature (IEC 250/DIN 53483)

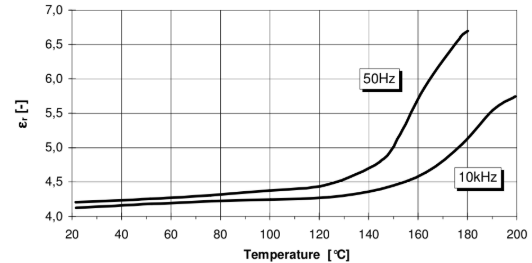

Dielectric constant εr vs temperature (IEC 250/DIN 53483)

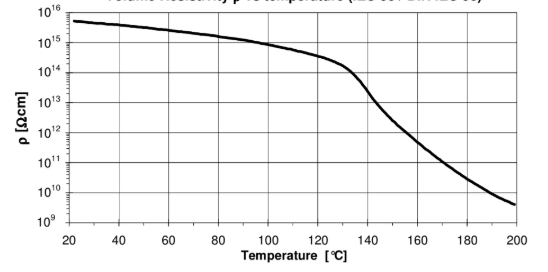

Volume Resistivity ρ vs temperature (IEC 93 / DIN IEC 93)

- Mechanical & Physical Properties

Property

Test Method

Unit

Value

Colour of castings

DIN 55 990

-

Black

Specific gravity

DIN 55 990

g/cm³

1.71

Flexural strength

ISO 178

MPa

90

Surface strain (failure)

ISO 178

%

1.4

Elastic modulus in flexion

ISO 178

MPa

7800

Critical stress intensity factor (K1C)

-

MPa·m¹/²

1.84

Specific energy at break (G1C)

-

J/m²

410

Glass transition temperature (DSC)

IEC 61006

°C

144

Coefficient of linear thermal expansion

DIN 53 752

ppm/K

38

Thermal conductivity

VDE 0304

W/m·K

0.65

Water absorption (10 days at 23°C)

ISO 62

% by wt.

0.08

Water absorption (30 min at 100°C)

ISO 62

% by wt.

0.05

Safety & Health

- First Aid

- Contamination of the eyes by resin, hardener or casting mix should be treated immediately by flushing with clean, running water for 10 to 15 minutes. A doctor should then be consulted.

- Material smeared or splashed on the skin should be dabbed off, and the contaminated area then washed and treated with a cleansing cream (see above). A doctor should be consulted in the event of severe irritation or burns. Contaminated clothing should be changed immediately.

- Anyone taken ill after inhaling vapours should be moved out of doors immediately. In all cases of doubt call for medical assistance.

- Industrial Hygiene

Mandatory and recommended industrial hygiene procedures should be followed when- ever our products are being handled and processed.

- Safety Precautions

Safety Precautions at Workplace

Protective Clothing: Yes

Gloves: essential

Arm Protectors: Recommended when skin contact likely

Goggles/Safety Glasses: Yes

Respirator/Dust Mask: NoSkin Protection

Before Starting Work: Apply barrier cream to exposed skin

After Washing: Apply barrier or nourishing cream

Cleansing of Contaminated Skin: Dab off with absorbent paper, wash with warm water and alkali-free soap, then dry with disposable towels. Do not use solvents.Clean Shop Requirements

Cover workbenches: Cover with light-colored paper. Use disposable beakers, etc.

Disposal of Spillage: Soak up with sawdust or cotton waste and deposit in a plastic-lined bin.Ventilation

Ventilation of Workshop: Renew air 3 to 5 times an hour

Ventilation of Workplace: Exhaust fans. Operatives should avoid inhaling vapors.

Storage & Handling

- Storage Conditions

Store the components in a dry place at 2-40°C, in tightly sealed original containers. Under these conditions, the shelf life will correspond to the expiry date stated on the label. After this date, the product may be processed only after reanalysis. Partly emptied containers should be tightly closed immediately after use.

Other

- Application Information

Value Units Test Method / Conditions Mix Ratio 0.28 %(W) %(W) Hardener : Resin