Enhanced TDS

Identification & Functionality

- Chemical Family

- RTU Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Features and Benefits

- Good impregnation capability.

- Excellent thermal endurance.

- Very good thermal shock restistance.

Applications & Uses

- Composites Processing Methods

- Product End Uses

- System Preparation

Preparation

Because of the tendency to sedimentation of the filler,filled components in principle require stirring before removal from the original containers. To avoid errors in dosage this step is especially important when removing only part of the contents. To facilitate stirring and removal, highly-filled components are heated to 60-80°C in the original container (e.g. overnight in an oven).

Mixing

To prepare the casting mix the resin component should be homogenized in holding tank A at 80-90°C under a vacuum of 1-5 mbar, the hardener component in holding tank B at 30-40°C and a vacuum of 1-5 mbar. A metering unit should be used to feed the resin and hardener components to an impeller mixer.

Curing

To determine whether cross-linking has been carried to completion and the final properties are optimal, it is necessary to carry out relevant measurements on the actual object or to measure the glass transition temperature. Different gel and cure cycles in the customer’s manufacturing process could lead to a different degree of cross-linking and thus a different glass transition temperature.

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

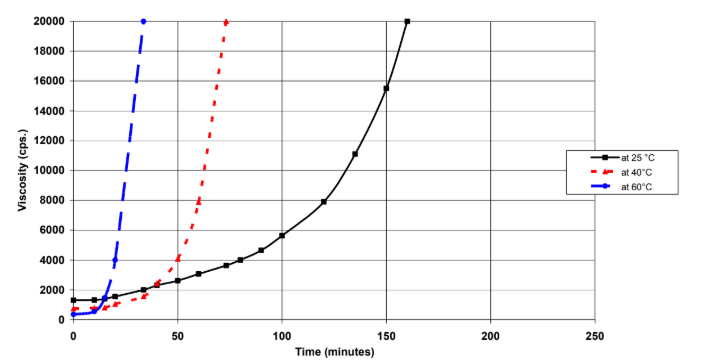

- Viscosity vs Time Graph

- Electrical Properties

Cure: 12 hr/23°C + 3 hr/95°C

Property

Value Range

Dielectric Strength (kV/mm)

27.9 at 2 mm thickness

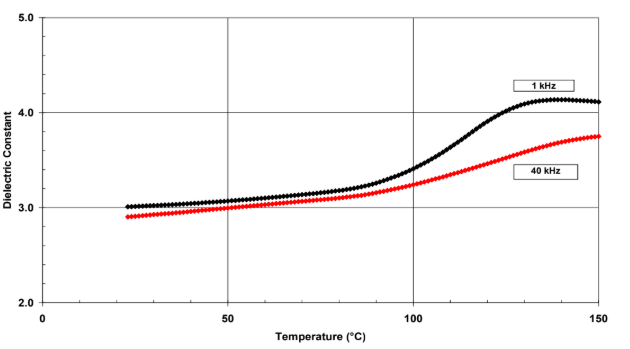

Dielectric Constant

See Figure 3

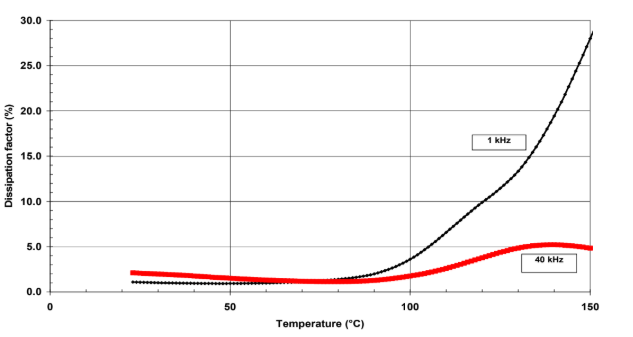

Dissipation Factor

See Figure 4

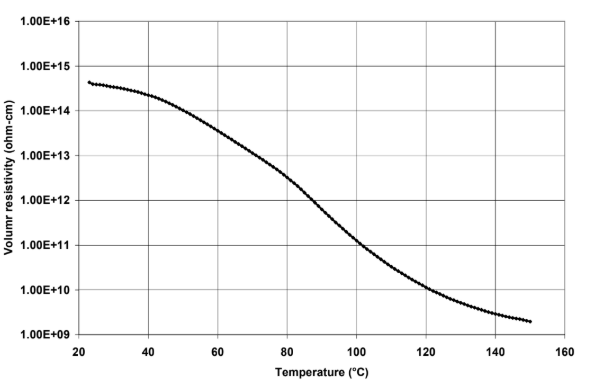

Volume Resistivity

See Figure 5

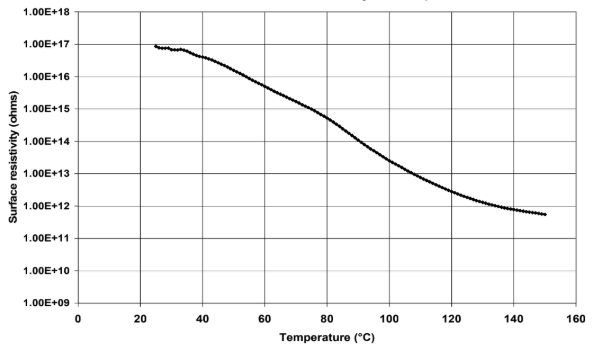

Surface Resistivity

See Figure 6

Figure 3 Dielectric Constant vs Temperature

Figure 4 Dissipation Factor vs Temperature

Figure 5 Volume Resistivity vs Temperature

Figure 6 Surface Resistivity vs Temperature

- Physical Properties

Cure: 12 hr/23°C + 3 hr/95°C

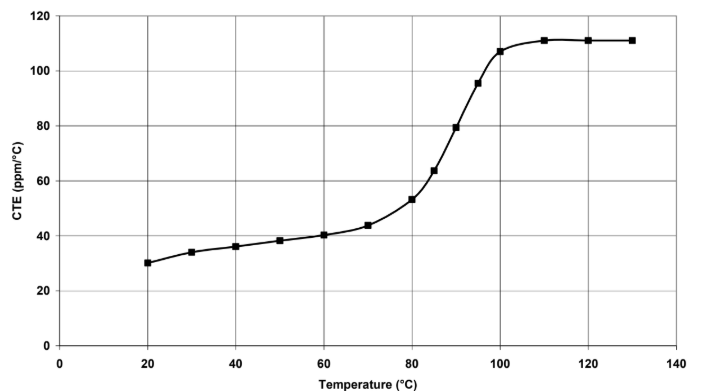

Property Value Range Flexural Strength (psi) 9,000 – 12,000 Flexural Modulus (psi) 520,000 – 540,000 Hardness (Shore D) 78 - 84 Glass Transition Temperature (°C) 90 - 95 Coefficient of Thermal Expansion (in/in-°C) See Figure Linear Shrinkage (%) Less than 0.005 inches/inch Cure: 12 hours at 23°C + 3 hours at 95°C

Coefficient Linear Thermal Expansion v. Temperature

- Typical Properties

Unless otherwise stated, the data were determined with typical production batches using standard test methods. They are typical values only, and do not constitute a product specification. Data is collected on cured standard specimen at 23 °C. The specimens are cured 2h/80°C + 1h/120°C + 2h/200°C.

Physical Property Value Test Method Color of casting Black Visual Density of cured casting, g/cm3 1.70 - 1.72 ISO 1183 Glass transition temperature by DSC, °C 200-230 ISO 11357-2 Thermal class N IEC 60085 Modulus in torsion G' at 25°C, MPa 4250 - 4350 ISO 6721 Flexural strength, MPa 79.5 - 80.5 ISO 178 Flexural modulus, MPa 6,900 - 7,100 ISO 178 Flexural elongation, % 1.15 - 1.25 ISO 178 Tensile strength, MPa 37.5 - 38.5 ISO 527 Tensile modulus, MPa 7900 - 8100 ISO 527 Elongation at break, % 0.45 - 0.55 ISO 527 Critical stress intensity factor (K1c), MPa.m1/2 1.8 - 1.9 Specific energy at break (G1c), J/m2(calculated) 425 - 435 Coefficient of thermal expansion, a1, ppm/K 38 - 42 ISO 11359-2 eq. ASTM E1545 Thermal conductivity, W/m.K 0.6 - 0.7 ISO 8894-1 Hardness Shore D 89 - 91 DIN 53505 Water absorption, % by weight

10 days at 23 °C

30 minutes at 100 °C

0.40 - 0.50

0.11 - 0.13ISO 62/80 Electrical Property

Dielectric strength, kV/mm (1 mm thick) 39.5 - 40.5 IEC 60243-1 Dielectric constant (&r) at 50Hz, 25 ℃ 4.55-4.65 IEC 60250 Dissipation factor (tan 8) at 50Hz, 25 ℃, % 1.5-2.5 IEC 60250 Volume resistivity (p) 25℃, ncm 1 x 1015 IEC 60093 Tracking resistance, CTI > 600 IEC 60112 Electrolytic corrosion, Grade A-1 IEC 60426 - Standard Cure Cycle

2 h at 80°C + 1 h at 120°C + 2 h at 200°C

- Processing Guidelines

Gel time at 25°C (120 grams), minutes : 170 - 220

Gel time at 40C (10 grams), minutes : 100 - 150

Gel time at 60C (10 grams), minutes : 30 - 35Recommended cure time: 12 hours @ 23°C + 3 hours @ 95°C

Storage & Handling

- Storage Conditions

Store the components in a dry place in tightly sealed original containers. Under these conditions, the shelf life will correspond to the expiry date stated on the label. Partly emptied containers should be tightly closed immediately after use.

Other

- Application Information

Value Units Test Method / Conditions Mix Ratio 0.33 %(W) Hardener : Resin