Enhanced TDS

Identification & Functionality

- Chemical Family

- RTU Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Product Features

- High mechanical and electrical properties

- High thermal shock resistance

Applications & Uses

- Composites Processing Methods

- Product End Uses

- System Preparation

General instructions for preparing liquid resin systems

Long pot life is desirable in the processing of any ARALDITE casting resin system. Mix all of the components together very thoroughly at room temperature or slightly above and under vacuum. Intensive wetting of the filler is extremely important. Proper mixing will result in:- Better flow properties and reduced tendency to shrinkage

- Lower internal stresses and therefore improved mechanical properties on object

- Improved partial discharge behaviour in high voltage applications.

For the mixing of medium- to highviscous ARALDITE casting resin systems and for mixing at lower temperatures, we recommend special thin film degassing mixers that may produce additional self-heating of 10-15 K as a result of friction. For low viscous ARALDITE casting resin systems, conventional anchor mixers are usually sufficient. The prefilled ARALDITE resin and ARADUR hardener can be stored at elevated temperature (about 60°C) for up to about 1 week, depending on formulation. Intermittent agitation during storage is advisable to prevent filler sedimentation.

Mixing time can vary from 0.5 to 3 hours, depending on mixing temperature, quantity, mixing equipment and the particular application. The required vacuum is 0.5 to 8 mbar. The vapour pressure of the individual components should be taken into account.- Applications

Dry type Distribution Transformer

Technical Details & Test Data

- Gelation / Cure Time

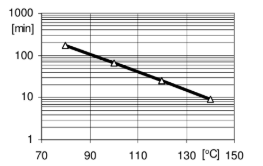

Fig.4.4: Geltime in function of temperature

(measured with Gelnorm Instrument, DIN 16945/6.3.1.)- Specific Instructions

The effective pot-life is about 2 days at temperature below 25°C. Conventional batch mixers should be cleaned once a week or at the end of work. For longer interruptions of work, the pipes of the mixing and metering installations have to be cooled and cleaned to prevent sedimentation and/or undesired viscosity increase. Interruptions over a weekend (approx. 48h) without cleaning are possible if the pipes are cooled at temperature below 18°C.

Viscosity increase and gel time at various temperatures, refer to Fig.4.1 and Fig.4.4.

Mould temperature

APG process : 130 - 160°C

Conventional vacuum casting : 70 - 100°C

Demoulding times (depending on mould temperature and casting volume)

APG process : 10 - 40 min

Conventional vacuum casting : 5 - 8h

Cure conditions

APG process (minimal postcure) : 4h at 130°C or 3h at 140°C

Conventional vacuum casting : 12h at 130°C or 8h at 140°CTo determine whether crosslinking has been carried to completion and the final proper-ties are optimal, it is necessary to carry out relevant measurements on the actual object or to measure the glass transition temperature. Different gelling and cure cycles in the manufacturing process could lead to a different crosslinking and glass transition temperature respectively.

- Mechanical & Physical Properties

System tested:

ARALDITE CW 5857-1 CI / ARADUR HW 5858-1 CI

Mix ratio: 100 / 100 pbw

Determined on standard test specimen at 23°C

Cured for 6h at 80°C + 10h at 130°CTensile strength

ISO 527

MPa

ca. 45

Elongation at break

ISO 527

%

ca. 0.75

E modulus from tensile test

ISO 527

MPa

ca. 10000

Critical stress intensity factor (KIc)

-

MPa.m1/2

ca. 2.6

Specific energy at break (GIc) - J/m2 ca. 630 Glass transition temperature (DSC)

IEC 1006

°C

ca. 60

Mean value for temperature range: <Tg

ppmK-1

ca. 43

Mean failure temperature

°C

-35

Limited oxygen index (LOI)

ASTM D2863/95

%

28

Storage & Handling

- Storage Conditions

ARADUR HW 5858-1 CI is sensitive to moisture. Partly emptied containers must be resealed immediately. Prefilled, liquid products always show filler sedimentation. Before partial use we recommend to stir up carefully the components or to use each container as complete unity.

Store the components dry at 18-40°C, in tightly sealed original containers. Under these conditions, the shelf life will correspond to the expiration date stated on the label. After this date, the product may be processed only following reanalysis. Partly emptied containers should be closed tightly immediately after use.

Other

- Application Information

Value Units Test Method / Conditions Mix Ratio 1.0 %(W) %(W) Hardener : Resin