Enhanced TDS

Identification & Functionality

- Blend

- No

- CASE Ingredients Functions

- Chemical Family

- Composite Materials Functions

- Function

- Resin

- Plastics & Elastomers Functions

- Single Ingredient

- Yes

- Technologies

- Product Families

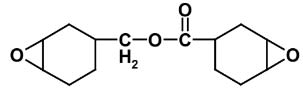

- Chemical Structure

Features & Benefits

- CASE Ingredients Features

- Materials Features

- Product Features

- Low viscosity coupled with long working life

- High heat deflection temperature

- Excellent dielectric properties that remain low over a wide range of temperatures

- Superior arc, corona and tracking resistance

- High endurance under outdoor (UV) exposure

Applications & Uses

- Composites Processing Methods

- Plastics & Elastomers End Uses

- Markets

- Applications

Properties

- Physical Form

Regulatory & Compliance

- Certifications & Compliance

- Chemical Inventories

Technical Details & Test Data

- Formulation Information

- Although ARALDITE® CY 179-1 may be cured with nearly all carboxylic acid anhydrides, ARADUR® HT 907 is best recommended for outdoor electrical applications. Such systems offer superior arc & track resistance, excellent mechanical & electrical properties and very good handling characteristics, especially when used in conjunction with Accelerator DY 183.

- The properties of ARALDITE® CY 179-1 systems at room temperature can be enhanced by the incorporation of the Flexibilizer DY 040. For example, by adding DY 040 at levels of 10-40 parts per hundred parts of resin (phr) by weight, it is possible to improve the handling characteristics of the mixture, reduce the raw material cost and improve the mechanical performance of the cured system.

- Accelerator DY 183 is used at levels up to 12 phr, dependent upon the mass and desired speed of cure.

- The Araldite® cycloaliphatic epoxy systems exhibit a sharp decrease in viscosity with temperature. These low viscosities permit the incorporation of large proportions of inorganic fillers, e.g., over 400 phr. or 65% by weight. The use of such fillers is recommended for casting for electrical or electronic applications to reduce exotherm, shrinkage, coefficient of linear thermal expansion, as well as cost.

- Typical Physical Properties

- Unless otherwise stated, the data were determined with typical production batches using standard test methods. They are typical values only, and do not constitute a product specification.

- Curing is best accomplished by first gelling at 80°C to 120°C (176°F - 248 °F) for 1 hour or more followed by higher curing temperature of 120°C - 200°C (248 °F - 392°F). The curing condition is dependent on the resin system used and the desired properties.

- Processing Information

- ARALDITE® CY 179-1 is preheated to a temperature greater than the melting point of the anhydride used, e.g. 50°C-60 °C (120 °F-140 °F) when using ARADUR® HT 907. ARADUR® HT 907 in its liquid state (min.40°C or 104°F) can then be added and mixed readily with the resin. The mixture can then be cooled to room temperature if desired. Accelerators and/or other modifiers such as DY 040 should then be added to the resin/hardener mixture at the desired process temperature. Separate mixtures of DY 040 and anhydride are to be avoided since there is a risk of a reaction between such components.

- Casting is best accomplished by using molds preheated to a temperature approximately 10°C higher than that of the casting mixture. A practical procedure is to first mix the resin, hardener and modifier; then stir in the filler. Mix thoroughly under vacuum of 2 to 6 torr to de-air. The accelerator is best added last, immediately prior to casting.

- The pot life at room temperature, as measured by viscosity versus time, is more than eight hours. For example, 100 phr Araldite® CY 179-1 US + 105 phr ARADUR® HT 907 + 12 phr Accelerator DY 183 remains below 4000 cPs for 16 hours at 25°C, exhibiting an initial viscosity of > 400 cPs.

Effect of Flexibilizer DY 040 on Mechanical Properties

- Curing cycle

- Gel at 80°C (176°F) + 6 hours at 120°C (248°F) or Gel at 80°C (176°F) + 4-6 hours at 140°C (284°F)

- Test specimen size for water absorption: 60 x 10 x 4 mm

Packaging & Availability

- Regional Availability

Other

- Appearance

- Liquid

- Color (SDS)

- Colorless

- Odor (SDS)

- Slight

- Chemical Properties

Value Units Test Method / Conditions Epoxy Equivalent Weight 128.0-145.0 g/eq g/eq ISO 3001 - Physical Properties

Value Units Test Method / Conditions Density 1.15-1.18 g/cm³ g/cm³ ISO 4630 at 25°C Flash Point 118.0 °C °C Closed Cup Flash Point 118.0 °C °C ISO 1523 Viscosity 100.0-600.0 mPa.s mPa.s ASTM D445 at 25°C