Enhanced TDS

Identification & Functionality

- Chemical Family

- RTU Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Key Properties

- Produces homogeneous winding impregnation with excellent mechanical and dielectrical properties.

- Very good adhesion.

- High thermal load capacity.

- Key Properties

- Homogeneous, adhesive, mechanically and electrically high-quality winding impregnations. High thermal load capacity.

Applications & Uses

- Composites Processing Methods

- Product End Uses

- Application Method

- Trickle process using any of the common impregnation equipment

- Processing Information

Preheat the stator or rotor to 120-130°C for the impregnation process. Mount it in a fixture for rotation at 15-20 rpm. Incline the axis at 15-20° to the horizontal. Trickle carefully the prepared resin/hardener mix onto the upper end of the winding. When it strikes the hot winding, the mix will become very fluid and flow into the winding under the influence of gravity, capillary action and centrifugal force. All air will be expelled from the winding as the mix penetrates.

When the mix reaches the lower end of the winding, diskontinue trickling and shift the unit’s axis to the horizontal. Continue rotation in this position until the mix has gelled and solidified. This procedure keeps the mix from dripping off, thus minimizing losses and cleaning work. A post-cure at an elevated temperature (³ 30 min at 130°C) is recommended.

The length of time required for impregnation up to gelling of the mix depends on the size of the winding, the diameter of the wire and the reactivity of the impregnation system as well as the preheating temperature of the windings. It is advisable to run preliminary tests to establish the exact cycle time and resin quantity required per winding. With ideal settings up to 600 units can be impregnated per hour, depending on the trickling equipment used and the size of the given winding.

- Processing Methods

- The trickle method of applying solvent-free Araldite epoxy impregnating resin systems is suitable for insulating the round-wire windings of any axially symmetrical coil with windings parallel to the coil’s axis.

- This very economical impregnation method is mainly used for insulating and reinforcing the motor windings of smaller electrical power tools and household appliances. Besides facilitating simplified design, it is processed under favorable conditions and opens the way to efficient, automatic production.

- The process guarantees homogeneous distribution of the impregnation mix, thus enhancing the balance of the component. The excellent mechanical and dielectric properties of the Araldite epoxy trickle resin systems - even at increased service temperatures and severe dynamic loads - contribute to a higher service life of the impregnated components.

Properties

- Physical Form

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Additional Notes

Compatibility between the wire enamel and the trickling resin system can vary among wires of different manufacturers even for enamels with the same chemical structure. Where doubt exists, always run a few practical tests before starting regular production. To enhance heat dissipation in the winding - especially in the case of high power ratings and heavy wire diameters - fillers can be added to the trickle impregnation resin system. The amount added depends on the final properties required and on the processing capabilities of the trickle impregnation equipment used. For example, certain automatic trickle units are capable of processing only impregnation systems with viscosities lower than 2000 mPa×s. The viscosity can be adjusted by preheating the mix to about 40°C in the storage tank.

- Cured Properties

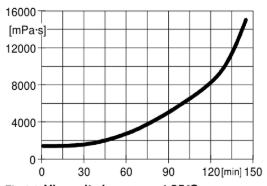

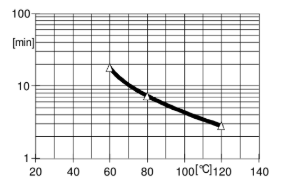

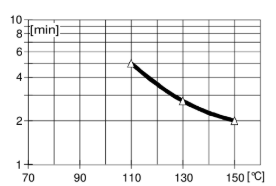

Viscosity Increase and Geltime

Fig.4.1: Viscosity increase at 25°C (measurements with Hoeppler)

Fig.4.3: Geltime measured with Gelnorm Instrument as a function of temperature (ISO 9396)

Fig.4.4: Geltime at thin layer as a function of temperature (measurements on heating plate)

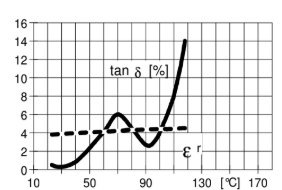

Dielectrical Properties

Determined on standard test specimen at 23°C Cured for 3h at 80°C + 3h at 130°C

Fig.4.5: Loss factor (tan δ) and dielectric constant (εr) as a function of temperature (measurement frequency: 50 Hz, IEC 60250)

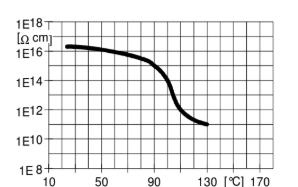

Fig.4.6: Volume resistivity (ρ) as a function of temperature (measurement voltage: 1000 V, IEC 60093)

Mechanical and Physical PropertiesProperty Test Method Unit Value Test Condition Tensile Strength ISO 527 MPa 65 - 75 Cured for 3h at 80°C + 3h at 130°C

Elongation at Break ISO 527 % 5 - 7 Cured for 3h at 80°C + 3h at 130°C

E Modulus from Tensile Test ISO 527 MPa 2300 - 2800 Cured for 3h at 80°C + 3h at 130°C

Flexural Strength ISO 178 MPa 105 - 115 Cured for 3h at 80°C + 3h at 130°C

Surface Strain ISO 178 % 8 - 9 Cured for 3h at 80°C + 3h at 130°C

E Modulus from Flexural Test ISO 178 MPa 2250 - 2650 Cured for 3h at 80°C + 3h at 130°C

Impact Strength ISO 179 kJ/m² 25 - 35 Cured for 3h at 80°C + 3h at 130°C

Glass Transition Temperature (DSC) ISO 11357-2 °C 90 - 105 Cured for 3h at 80°C + 3h at 130°C

Water Absorption (30 min at 100°C) ISO 62 % by wt. 0.40 - 0.50 Cured for 3h at 80°C + 3h at 130°C

Decomposition Temperature DTA °C > 350 Cured for 3h at 80°C + 3h at 130°C

Storage & Handling

- Storage Conditions

Store the components in a dry place according to the storage conditions stated on the label in tightly sealed original containers. Under these conditions, the shelf life will correspond to the expiry date stated on the label. After this date, the product may be processed only after reanalysis. Partly emptied containers should be tightly closed immediately after use.

Other

- Application Information

Value Units Test Method / Conditions Mix Ratio 0.3 %(W) %(W) Hardener : Resin