Enhanced TDS

Identification & Functionality

- Chemical Family

- RTU Product Type

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Ready-to-Use Product Features

Applications & Uses

- Application Area

- Composites Processing Methods

Properties

- Physical Form

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Process Flow

- The winding body is first preheated at 120-130°C for the impregnation process. It is then fixed in a rotating device with an inclination of 15-20° and rotated around its longitudinal axis at 15-20 rpm.

- The carefully mixed impregnating resin compound is drizzled onto the upper winding head. On contact with the hot wire winding, it immediately becomes very thin and penetrates the winding as a result of gravity and capillary and centrifugal forces. In the process, the air contained in the winding is completely displaced by the impregnating compound and expelled (single-flow principle).

- As soon as the impregnating resin compound reaches the lower winding head, the material flow is interrupted and the winding body is brought into a horizontal position. In this position, rotation continues until the impregnating compound solidifies and gels. This measure prevents dripping of the impregnating resin system and minimizes losses and cleaning and maintenance work. Post-curing at elevated temperature (> 30 min at 130°C) is recommended.

- The duration of the impregnation process until the resin mass gels depends on the winding dimension, wire thickness and reactivity of the impregnation system. The impregnation time and impregnating resin requirement per winding are determined and specified in preliminary tests. With the appropriate settings, up to 600 units per hour can be produced, depending on the type of automatic beading machine and winding dimension.

- Additional Notes

The compatibility between wire enamel and carrier resin system varies with wires from different manufacturers even with the same chemical enamel structure. In case of doubt, own object tests are recommended before starting series production. To improve heat dissipation in the winding body - especially for high-power windings and larger wire diameters - filler can be added to the drip-resin system. The possible amount to be added depends on the required end properties and the processing possibilities on commercially available automatic trickling machines. For example, only impregnating resin systems with a viscosity of < 2000 mPa-s can be processed on various automatic trickling machines. The viscosity can be adjusted by preheating the impregnating resin in the storage tank to approx. 40°C.

- Trickling Process

All rotationally symmetrical windings with an axis-parallel coil structure made of round wire are suitable for insulation by the trickle process using impregnating compounds based on solvent-free Araldite epoxy resin systems. This very economical impregnation method is mainly used for insulation and for strengthening the motor windings of electrical tools and household appliances. It allows design simplifications, offers favorable processing conditions and enables a trouble-free automated manufacturing process.

The process guarantees homogeneous distribution of the impregnation mass, which is very advantageous in terms of balancing and concentricity. The high mechanical and dielectric end properties of Araldite epoxy resin systems, even at elevated operating temperatures and under strong dynamic loads, result in above-average service life expectations.

- Properties

Mechanical and physical properties

Property Value Unit Test Method Condition Tensile Strength 75 - 85 MPa ISO R 527 at 23°C, Curing: 3h at 80°C + 3h at 130°C.

Elongation at Break 5 - 7 % ISO R 527 at 23°C, Curing: 3h at 80°C + 3h at 130°C.

E-Modulus from Tensile Test 2300 - 2800 MPa ISO R 527 at 23°C, Curing: 3h at 80°C + 3h at 130°C.

Flexural Strength 125 - 135 MPa ISO 178 at 23°C, Curing: 3h at 80°C + 3h at 130°C.

Edge Fiber Stretch 8 - 9 % ISO 178 at 23°C, Curing: 3h at 80°C + 3h at 130°C.

E-Modulus from Bending Test 2450 - 2850 MPa ISO 178 at 23°C, Curing: 3h at 80°C + 3h at 130°C.

Impact Strength 40 - 50 kJ/m² ISO 179 at 23°C, Curing: 3h at 80°C + 3h at 130°C.

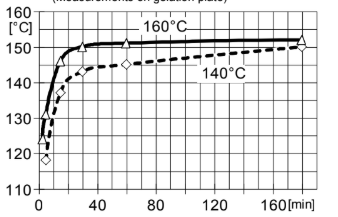

Glass Transition Temperature (DSC) 140 – 150 °C ISO 11357-2 at 23°C, Curing: 3h at 80°C + 3h at 130°C.

Water Intake (Test specimen: 50x50x4 mm) 0.15 - 0.25 Gew.-% ISO 62 30 min at 100°C, at 23°C, Curing: 3h at 80°C + 3h at 130°C.

Thermal Class 155 (F) °C IEC 60085 at 23°C, Curing: 3h at 80°C + 3h at 130°C.

Decomposition Temperature (Heating rate) > 350 °C TGA heating rate: 10 K/min, at 23°C, Curing: 3h at 80°C + 3h at 130°C.

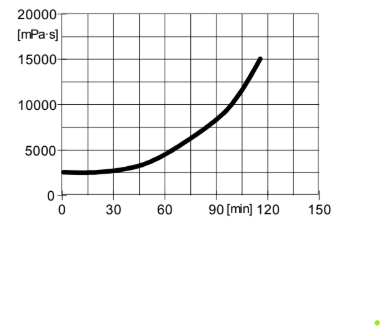

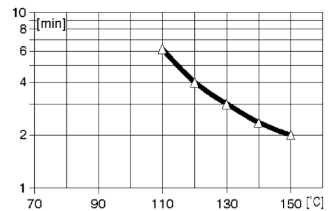

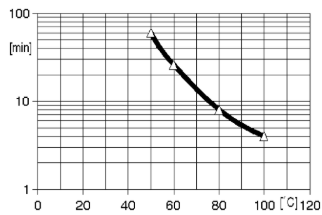

Viscosity profile and Gelation

Fig.4.1: Viscosity Curve at 25°C (Measurements with Hoeppler, ISO 12058)

Fig.4.2: Gelation times as a function of temperature, in thin layer (Measurements on gelation plate)

Fig.4.3: Gelation times as a function of temperature (Messungen acc. to ISO 9396)

Fig.4.4: Glass transition temperature as a function of curing time (isothermal hardening, ISO 11357-2)

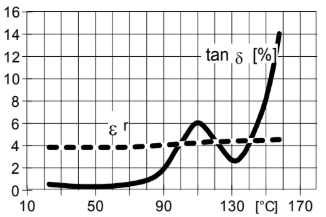

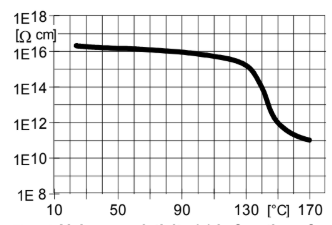

Dielectric Properties

Fig.4.5: Dielectric loss factor (tan δ) and dielectric constand εr) as a function of temperature (Measurement Frequency: 50 Hz, IEC 60250)

Fig.4.6: Volume resistivity (ρ) in function of temperature (Measurement Voltage: 1000 V, IEC 60093/)

Storage & Handling

- Storage Conditions

- The components must always be stored well closed and dry, if possible in the original containers. Under these conditions, the shelf life corresponds to the expiry date indicated on the product label. After this date, the product may only be further processed after a new analysis. Opened containers must be closed tightly again immediately after use.

Other

- Application Information

Value Units Test Method / Conditions Mix Ratio 0.32 %(W) %(W) Hardener : Resin