Enhanced TDS

Identification & Functionality

- Chemical Family

- Fillers Included

- RTU Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Key Properties

- Hydrophobicity transfer and recovery

- Good mechanical properties

- Good dielectric properties

- Very good thermal shock resistance

- High erosion resistance under UV radiation

- High tracking and arc resistance

- Extended insulation life-time

Note : The use of silanized silica flour produces stable dielectric properties under humid, outdoor conditions.

Applications & Uses

- Application Area

- Composites Processing Methods

- Cure Method

- Product End Uses

- Markets

- Applications

- Processing Methods

- Automatic pressure gelation process (APG)

- Conventional gravity casting process under vacuum

- Additional Information

This product data was based on two system formulations:

Component System A (pbw) System B (pbw) Araldite® CY 5622 Resin 100 100 Aradur® HY 1235-1 82 82 Accelerator DY 062 0.45 0.45 Filler: Silica Flour (Silanized) 325 355 The following color pastes may be used :

Araldite® DW 9134 BD (gray)

Araldite® DW 0126 (brown)- Remarks

Araldite® CY 5622 epoxy resin is supplied with a gel-like consistency. It is liquefied by stirring. To adjust a suited viscosity range of the resin, the temperature of the resin at the beginning of the stirring process should be above 6 °C, and below 30°C. In case of longer exposure to temperatures below 6 °C the temperature should be controlled inside in the middle of the packaging before stirring. If the temperature inside the bulk of the product is measured to be below 6 °C the packaging should be heated smoothly from out side (best from below) with max. 30 °C. As this warming process may take up to several weeks depending on size of packaging and temperature conditions, the lead times and storage space should be adjusted in winter accordingly. The resin heats up due to the stirring, the maximum temperature should be 40 °C. Special mixing equipment is needed, as it has to be introduced via the hole of the container. To achieve sufficient and homogenous stirring effect, the stirrer should extend inside the container and a special design is needed for rectangular containers such as a tote. Such design has to ensure that all liquid in edges is sufficiently homogenized. A dynamic torque controlled motor will be needed as the stirring has to start smoothly. Recommendations for suited stirrer equipment are available on request. Transferring the gel-like structure into a normal, low viscous liquid might take several hours. During consumption of the resin, it should be stirred 5 – 15 minutes / hour.

Properties

- Physical Form

Technical Details & Test Data

- Typical Electrical Properties

Test Values System A

Filler load : 64 %System B

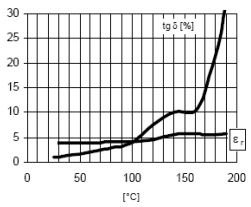

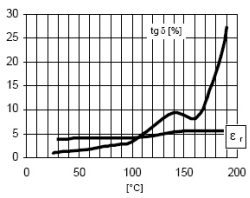

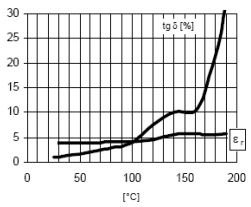

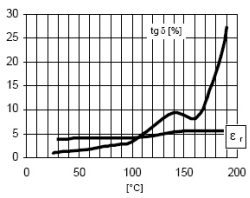

Filler Load : 66 %Test Method Breakdown Strength, kV/mm 21 – 26 21 – 26 IEC 602243-1 HV Diffusion breakdown strength, Class HD – Class 2 HD – Class 2 DIN 57 441 Temperature of specimen after test, °C (°F) < 24 (75) < 24 (75) HV Arc Resistance, s 183 – 186 184 – 186 IEC 61621 Tracking Resistance, CTI With test solution A > 600 0.0 > 600 0.0 With test solution B > 600 M 0.1 > 600 M 0.1 HV Tracking Resistance, Class n/a 1B4.5 IEC 60587 Electrolytic Corrosion, Grade A-1 A-1 IEC 60426 Fig. 7.1 Loss factor (tan 8) and dielectric constant (er) as a function of a function of temperature System A: 64% filler content

Fig. 7.2 Loss factor (tan 8) and dielectric constant (er) as a function of a function of temperature System B: 66% filler content

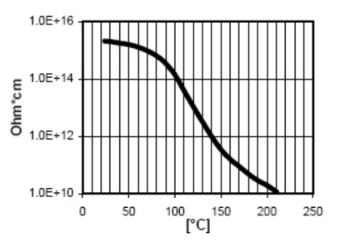

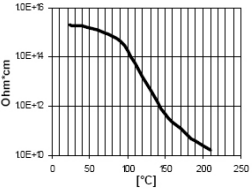

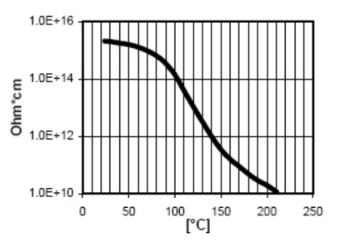

Fig. 7.3 Volume resistivity (p) as a function of temperature System A: 64% filler content

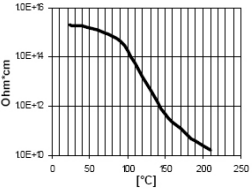

Fig. 7.4 Volume resistivity (p) as a function of temperature System B: 66% filler content

- Process Viscosity

System A : 100 parts Araldite® CY 5622 + 82 parts Aradur® HY 1235-1 + 0.45 part Accelerator DY 062 + 325 parts Silica flour silanized (System A) OR 355 parts (System B).

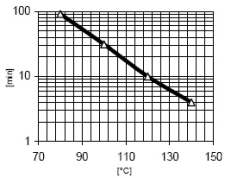

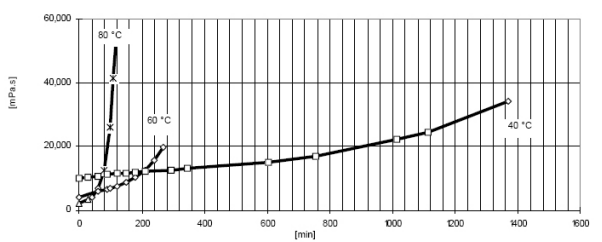

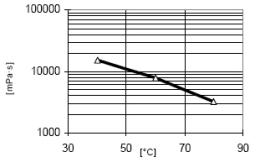

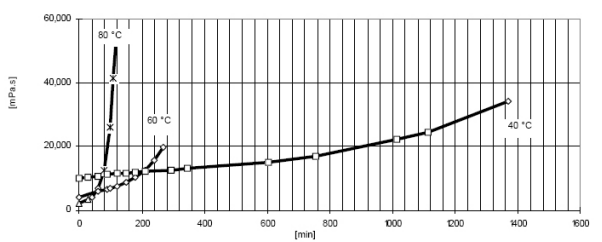

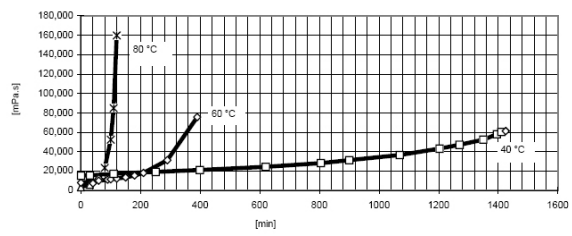

Fig. 5.1 Viscosity increase at 40°C, 60°C and 80°C*: System A: 64% filler content

*40°C = 104°F; 60°C = 140°F; 80°C = 176°F

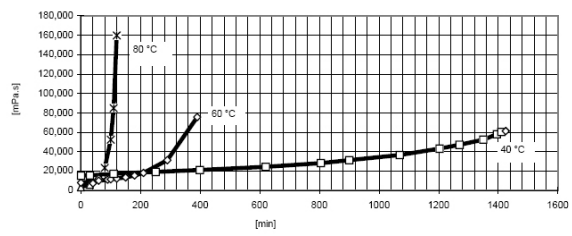

Fig. 5.2 Viscosity increase at 40°C, 60°C and 80°C*: System B: 66% filler content

*40°C = 104°F; 60°C = 140°F; 80°C = 176°F

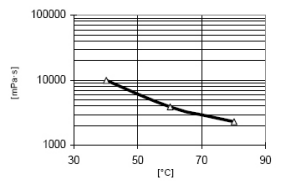

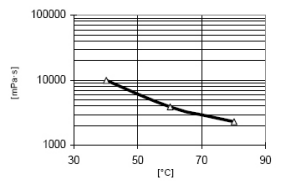

Fig. 5.3 Initial viscosity as a function of temperature System A: 64% filler content

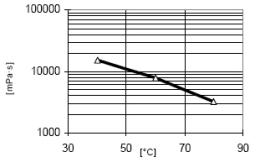

Fig. 5.4 Initial viscosity as a function of temperature System B: 66% filler content

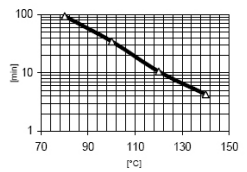

Gelation and Cure Times

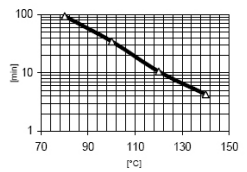

System A : 100 parts Araldite® CY 5622 + 82 parts Aradur® HY 1235-1 + 0.45 part Accelerator DY 02 + 325 parts Silica flour silanized (System A) OR 355 parts (System B).(Measurements with Gelnorm Instrument / DIN 61945)Fig. 5.5 Gel time measured as a function of temperature System A: 64% filler content

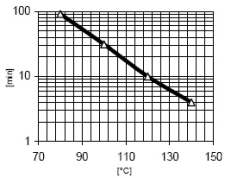

Fig. 5.6 Gel time measured as a function of temperature System B: 66% filler content

- Typical Mechanical and Physical Properties

Determined on standard specimen at 23 °C (73 °F)

Cured for 6 hours at 80 °C (176 °F) + 10 hours at 140 °C (284 °F)Property Unit System A System B Test Method Tensile Strength

MPa 65 - 90

9,425 – 13,05080 - 105

11,600 – 15,225ISO 527

Psi Elongation at break % 0.80 - 1.20 1.20 - 1.60 - E modulus from tensile test

MPa 10,600 – 11,000

1,537 – 1,59511,300 – 11,700

1,638 - 1,696-

Ksi Flexural Strength

MPa 125 - 145

18,125 – 21,025130 – 150

18,850 – 21,750ISO 178

Psi Surface Strain % 1.30 – 1.60 1.35 – 1.65 - E modulus from flexural test

MPa 11,000 - 11,500

1,595 – 1,66811,300 – 11,800

1,638 – 1,711-

Ksi Double Torsion Test Critical stress intensity factor (Kᵢ꜀) MPa m.¹/² 2.30 - 2.50 2.40 - 2.60 CG 216 Specific energy at break (Gᵢ꜀) J/m² 460 - 500 490 - 530 IEC 61006 Glass transition temperature, DSC

°C 100 – 115

212 - 239100 – 115

212 - 239IEC 61006

°F Coefficient of linear thermal expansion Mean value for temperature range: 20 – 80 °C (68 – 176 °F), K-1 34 – 37 x 10-6 32 – 35 x 10-6 Thermal Conductivity, W/m·K 0.90 - 1.00 0.95 - 1.05 ISO 8894 Water Absorption (specimen: 50 x 50 x 4 mm) 10 days at 23 °C (73 °F) % by wt. 0.10 – 0.15 0.10 – 0.15 ISO 62 60 min. at 100 °C (212 °F) % by wt. 0.07- 0.12 0.07- 0.12 ISO 62 Oxygen Index % -- 32 ASTM D-2863 Decomposition Temperature, Heating rate: 10 K/min. °C (°F) 350 (662) 350 (662) DTA Density g/cm3 1.83 - 1.92 1.85 - 1.95 ISO 1183 Filler Content % 64 66 - - Processing Information

For optimized processing, Huntsman recommends that users first prepare separate pre-mixtures of both a resin component containing the inorganic filler and a hardener component also containing inorganic filler. These two prepared components can be stored in separate, heated and agitated vessels under constant vacuum prior to use. In this case, the vessel temperatures should be kept between 50°C and 60°C (122°F and 140°F) at a vacuum range of between 1 and 8 mbar.

Preparation of pre-filled resin component- Stir Araldite® CY 5622 epoxy resin at low shear to liquefy

- Charge liquefied Araldite® CY 5622 epoxy resin to a mixer

NOTE : Special thin-film mixers are available that facilitate de-airing - Bring material to an elevated temperature with agitation (typically 50 – 60 °C / 122 – 140 °F)

- Charge selected inorganic filler(s)

NOTE : the moisture content of the filler should be less than 0.2 % for casting electrical components - Mix at elevated temperature under vacuum (1 to 8 mbar). Mixing times vary batch size in the range of 0.5 to 3 hours.

Preparation of pre-filled hardener component

- Charge Aradur® HY 1235-1 hardener to a mixer

NOTE 1 : Special thin-film mixers are available that facilitate de-airing

NOTE 2 : Aradur® HY 1235-1 hardener is a liquid anhydride and will react with moisture. Any prolonged contact of this material with ambient air should be avoided. Once opened, any unused portion in the container should be blanketed with dry nitrogen - Charge Accelerator DY 062

- Bring to an elevated temperature with agitation (typically 50 – 60 °C / 122 – 140 °F)

- Charge selected inorganic filler(s)

NOTE : the moisture content of the filler should be less than 0.2 % for casting electrical components - Mix at elevated temperature under vacuum (1 to 8 mbar). Mixing times vary with batch size in the range of 0.5 to 3 hours

Final Mixing of Prepared Pre-filled Components

In larger plants, particularly those employing the Automatic Pressure Gelation casting process, metering pumps are typically used to feed premixed resin and hardener components to a final continuous static or dynamic mixer. The mixed material is then delivered directly into the casting mold.

In smaller batch operations, the prepared components are typically weighed into a final batch mixing vessel. They are then mixed at temperatures typically of 50 °C to 80 °C (122 °F to 176 °F) with a vacuum of 1 to 8 mbar for a period of 0.5 to 3 hours depending on mix temperature, quantity and particular application.

Typical mold temperatures

APG process: 130 – 150 °C (266 – 302 °F)

Conventional vacuum casting: 80 – 100 °C (176 – 212 °F)

Typical de-molding times

APG process: 10 – 30 minutes

Conventional vacuum casting: 2 – 6 hours

Typical cure cycles

APG process: After de-molding, immediately post-cure either: 2 – 3 hours at 150 °C (302 °F) or 4 – 6 hours at 140 °C (284 °F)

Conventional vacuum casting: Gel at 80 – 100 °C (176 – 212 °F) for 2 – 6 hours (depending on part size and application) Parts may be de-molded after gelation then immediately post-cured. Post-curing varies with part size and application. For small parts post-cure can be 2 hours at 150 °C (302 °F)

For large parts, typical post-cures are at lower temperatures for longer times or may be ramped or done stepwise at increasing temperature increments- Typical Mechanical and Physical Properties

Determined on standard specimen at 23 °C (73 °F)

Cured for 6 hours at 80 °C (176 °F) + 10 hours at 140 °C (284 °F)Property Unit System A System B Test Method Tensile Strength

MPa 65 - 90

9,425 – 13,05080 - 105

11,600 – 15,225ISO 527

Psi Elongation at break % 0.80 - 1.20 1.20 - 1.60 - E modulus from tensile test

MPa 10,600 – 11,000

1,537 – 1,59511,300 – 11,700

1,638 - 1,696-

Ksi Flexural Strength

MPa 125 - 145

18,125 – 21,025130 – 150

18,850 – 21,750ISO 178

Psi Surface Strain % 1.30 – 1.60 1.35 – 1.65 - E modulus from flexural test

MPa 11,000 - 11,500

1,595 – 1,66811,300 – 11,800

1,638 – 1,711-

Ksi Double Torsion Test Critical stress intensity factor (Kᵢ꜀) MPa m.¹/² 2.30 - 2.50 2.40 - 2.60 CG 216 Specific energy at break (Gᵢ꜀) J/m² 460 - 500 490 - 530 IEC 61006 Glass transition temperature, DSC

°C 100 – 115

212 - 239100 – 115

212 - 239IEC 61006

°F Coefficient of linear thermal expansion Mean value for temperature range: 20 – 80 °C (68 – 176 °F), K-1 34 – 37 x 10-6 32 – 35 x 10-6 Thermal Conductivity, W/m·K 0.90 - 1.00 0.95 - 1.05 ISO 8894 Water Absorption (specimen: 50 x 50 x 4 mm) 10 days at 23 °C (73 °F) % by wt. 0.10 – 0.15 0.10 – 0.15 ISO 62 60 min. at 100 °C (212 °F) % by wt. 0.07- 0.12 0.07- 0.12 ISO 62 Oxygen Index % -- 32 ASTM D-2863 Decomposition Temperature, Heating rate: 10 K/min. °C (°F) 350 (662) 350 (662) DTA Density g/cm3 1.83 - 1.92 1.85 - 1.95 ISO 1183 Filler Content % 64 66 - - Typical Electrical Properties

Test Values System A

Filler load : 64 %System B

Filler Load : 66 %Test Method Breakdown Strength, kV/mm 21 – 26 21 – 26 IEC 602243-1 HV Diffusion breakdown strength, Class HD – Class 2 HD – Class 2 DIN 57 441 Temperature of specimen after test, °C (°F) < 24 (75) < 24 (75) HV Arc Resistance, s 183 – 186 184 – 186 IEC 61621 Tracking Resistance, CTI With test solution A > 600 0.0 > 600 0.0 With test solution B > 600 M 0.1 > 600 M 0.1 HV Tracking Resistance, Class n/a 1B4.5 IEC 60587 Electrolytic Corrosion, Grade A-1 A-1 IEC 60426 Fig. 7.1 Loss factor (tan 8) and dielectric constant (er) as a function of a function of temperature System A: 64% filler content

Fig. 7.2 Loss factor (tan 8) and dielectric constant (er) as a function of a function of temperature System B: 66% filler content

Fig. 7.3 Volume resistivity (p) as a function of temperature System A: 64% filler content

Fig. 7.4 Volume resistivity (p) as a function of temperature System B: 66% filler content

- Process Viscosity

System A : 100 parts Araldite® CY 5622 + 82 parts Aradur® HY 1235-1 + 0.45 part Accelerator DY 062 + 325 parts Silica flour silanized (System A) OR 355 parts (System B).

Fig. 5.1 Viscosity increase at 40°C, 60°C and 80°C*: System A: 64% filler content

*40°C = 104°F; 60°C = 140°F; 80°C = 176°F

Fig. 5.2 Viscosity increase at 40°C, 60°C and 80°C*: System B: 66% filler content

*40°C = 104°F; 60°C = 140°F; 80°C = 176°F

Fig. 5.3 Initial viscosity as a function of temperature System A: 64% filler content

Fig. 5.4 Initial viscosity as a function of temperature System B: 66% filler content

Gelation and Cure Times

System A : 100 parts Araldite® CY 5622 + 82 parts Aradur® HY 1235-1 + 0.45 part Accelerator DY 02 + 325 parts Silica flour silanized (System A) OR 355 parts (System B).(Measurements with Gelnorm Instrument / DIN 61945)Fig. 5.5 Gel time measured as a function of temperature System A: 64% filler content

Fig. 5.6 Gel time measured as a function of temperature System B: 66% filler content