Enhanced TDS

Identification & Functionality

- Chemical Family

- RTU Product Type

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Ready-to-Use Product Features

- Features and Benefits

- High temperature resistance

- FST (Fire Smoke & Toxicity)

- Meets EN 45545-2 category HL1 / HL2 on R1 / R7 applications

- Meets UL 94 V0/V1

- Halogen free

- Unfilled resin system with low viscosity for low temperature processing

- Fast RTM curing capability (ca. 5 minutes at 150 °C)

- Can pultrude at ca.10 meters per hour

- High modulus

- Features and Benefits

- High temperature resistance

- FST (Fire Smoke & Toxicity)

- Meets EN 45545-2 category HL1 / HL2 on R1 / R7 applications

- Meets UL 94 V0/V1

- Halogen free

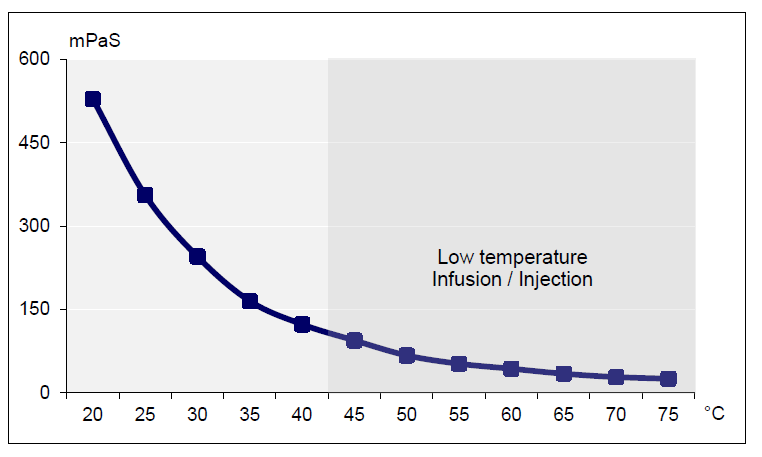

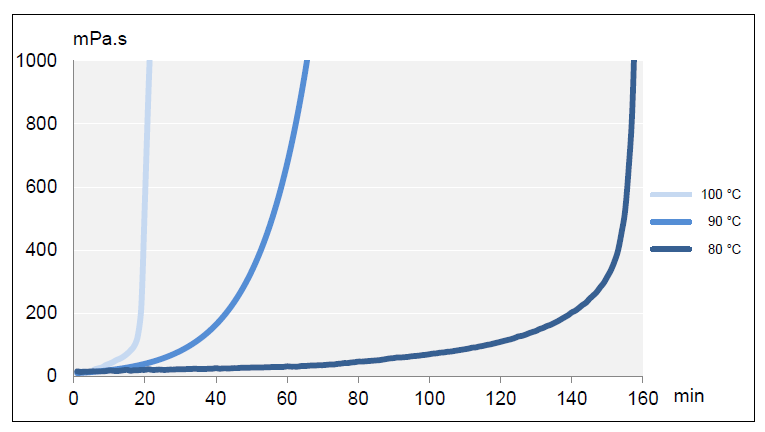

- Unfilled resin system with low viscosity for low temperature processing

- Fast RTM curing capability (ca. 5 minutes at 150 °C)

- Can pultrude at ca.10 meters per hour

- High modulus

Applications & Uses

- Composites Processing Methods

- Markets

- Applications

- Application Information

Araldite® FST 40004 / 40005 epoxy thermoset resin system with its FST properties suitable for manufacturing of composite parts such as battery box, automotive composites, railway, and interior aircrafts. The resin system can be processed by dynamic fluid compression molding DFCM), resin transfer molding (RTM), infusion, or pultrusion.

- Application Details

ARALDITE® FST 40004 / 40005 epoxy thermoset resin system with its FST properties suitable for manufacturing of composite parts such as battery box, automotive composites, railway, and interior aircrafts. The resin system can be processed by dynamic fluid compression molding (DFCM), resin transfer molding (RTM), infusion, or pultrusion.

Properties

- Physical Form

Regulatory & Compliance

- Certifications & Compliance

- Quality Standards

Technical Details & Test Data

- Cure Cycle

For large part: 1 hour at 100 °C + 1 hour at 120 °C

Demold to get free-standing parts

Post cure: 2 hours at 180 °C

For small or medium part: 5 minutes at 150 °C or 20 minutes at 120 °C

Demold to get free-standing parts

Post cure: 2 hours at 180 °C

For pultrusion: 10 meters per hourDepending on the application process, the required application and its economical, the curing cycle can be optimized to fit the required properties.

- Cured Properties

Initial mixed viscosity of Araldite® FST 40004 / 40005

Initial mixed viscosity of Araldite® FST 40004 / 40005

Key Value Unit Test Method Test Condition Glass Transition Temperature (Tg) 265 - 275 °C DMA, ISO 6721-4 at 2k/minute, G’ onset

Tensile Strength 40 - 50 MPa ISO 527 - Elongation at Break 1.0 - 2.0 % ISO 527 - E Modulus from Tensile Test 3,100 - 3,300 MPa ISO 527 - Fracture Toughness (K1C) 0.55 - 0.65 MPa·m½ ISO 13586 - Fracture Energy (G1C) 100 - 130 J/m² ISO 13586 - Interlaminar Shear Strength (ILSS) 48 - 52 MPa ASTM D2344 - Flame Retardant Properties (CFRP thickness) V1 - UL 94 CFRP thickness 2.0 mm, 50% FVC

Flame Retardant Properties (CFRP thickness) V0 - UL 94 CFRP thickness 3.2 mm, 50% FVC

Cured Conditions - - - Cured: 5 minutes at 150°C + 2 hours at 180°C

Safety & Health

- Safety Precautions

Huntsman Advanced Materials Americas LLC maintains up–to-date Safety Data Sheets (SDS) on all of its products. These sheets contain pertinent information that you may need to protect your employees and customers against any known health or safety hazards associated with our products. Users should review the latest MSDS to determine possible health hazards and appropriate precautions to implement prior to using this material.

Packaging & Availability

- Regional Availability

Storage & Handling

- Storage Information

- ARALDITE® FST 40004 should be stored in a dry place, in its sealed original container, at temperatures between 18°C - 40°C (64°F - 104°F). Under these storage conditions the shelf life is 1 year from the date of manufacture. The product should not be exposed to direct sunlight.

- ARALDITE® FST 40005 should be stored in a dry place, in its sealed original container, at temperatures between 2°C - 40°C (35°F - 104°F). Under these storage conditions the shelf life is 1 year from the date of manufacture. The product should not be exposed to direct sunlight.

- Storage Conditions

Araldite® FST 40004 should be stored in a dry place, in its sealed original container, at temperatures between 18°C - 40°C (64°F - 104°F). Under these storage conditions the shelf life is 1 year from the date of manufacture. The product should not be exposed to direct sunlight.

Araldite® FST 40005 should be stored in a dry place, in its sealed original container, at temperatures between 2°C - 40°C (35°F - 104°F). Under these storage conditions the shelf life is 1 year from the date of manufacture. The product should not be exposed to direct sunlight.

Other

- Application Information

Value Units Test Method / Conditions Mix Ratio 0.18 %(W) %(W) Hardener : Resin