Enhanced TDS

Identification & Functionality

- Blend

- No

- CAS Number

- 25068-38-6

- Chemical Family

- Chemical Name

- Composite Materials Functions

- Function

- Resins, Binders & Matrix Materials

- Polymer Name

- Single Ingredient

- Yes

- Synonyms

- (Chloromethyl)oxirane-4,4′-(1-methylethylidene)bisphenol copolymer, 1-Chloro-2,3-epoxypropane-4,4′-isopropylidenebisphenol polymers, 1-Chloro-2,3-epoxypropane-4,4′-isopropylidenediphenol polymer, 2,2-Bis(4-hydroxyphenyl)propane-epichlorohydrin copolymer, 2,2-Bis(4-hydroxyphenyl)propane-epichlorohydrin polymer, 2,2-Bis(hydroxyphenyl)propane-epichlorohydrin copolymer, 2,2-Bis(p-hydroxyphenyl)propane-epichlorohydrin condensate, 2,2-Bis(p-hydroxyphenyl)propane-epichlorohydrin copolymer, 2,2-Bis(p-hydroxyphenyl)propane-epichlorohydrin polymer, 2,2-Diphenylolpropane-epichlorohydrin polymer, 4,4′-Dihydroxydiphenylpropane-epichlorohydrin polymer, 4,4′-Isopropylidenediphenol-1-chloro-2,3-epoxypropane polymer, 4,4′-Isopropylidenediphenol-epichlorohydrin copolymer, 4,4′-Isopropylidenediphenol-epichlorohydrin polymer, Bis(p-hydroxyphenyl)dimethylmethane-epichlorohydrin copolymer, Bisphenol A-(chloromethyl)oxirane copolymer, Bisphenol A-epichlorohydrin condensate, Bisphenol A-epichlorohydrin copolymer, Bisphenol A-epichlorohydrin epoxy resin, Bisphenol A-epichlorohydrin polymer, Bisphenol A-epichlorohydrin resin, Bisphenol a-epichlorohydrin-benzyl alcohol copolymer, Bisphenol a-epichlorohydrin-dibenzylamine copolymer, Bisphenol A-epichlorohydrine copolymer, Bisphenol A-glycidyl chloride copolymer, Bisphenol A-p-cumylphenol-epichlorohydrin copolymer, Dian-epichlorohydrin copolymer, Dian-epichlorohydrin polymer, Diphenylolpropane-epichlorohydrin copolymer, Diphenylolpropane-epichlorohydrin polymer, Epichlorohydrin-2,2-bis(4-hydroxyphenyl)propane copolymer, Epichlorohydrin-2,2-bis(4-hydroxyphenyl)propane polymer, Epichlorohydrin-4,4′-dihydroxydiphenylpropane copolymer, Epichlorohydrin-4,4′-isopropylidenediphenol copolymer, Epichlorohydrin-4,4′-isopropylidenediphenol polymer, Epichlorohydrin-bisphenol A copolymer, Epichlorohydrin-bisphenol A epoxy resin, Epichlorohydrin-bisphenol A polymer, Epichlorohydrin-bisphenol A resin, Epichlorohydrin-diphenylolpropane polymer, NSC 11096

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Materials Features

Applications & Uses

- Composites End Use

Properties

- Physical Form

Regulatory & Compliance

- Certifications & Compliance

- Chemical Inventories

Technical Details & Test Data

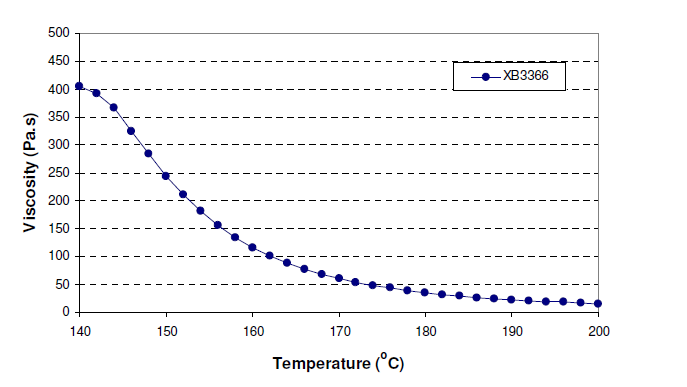

- Viscosity vs Temperature Graph

Safety & Health

- Handling and Safety Information

Forced ventilation and dust masks or respirators should be used to ensure that operatives do not breath in dust generated by the system.

Personal hygiene

Safety precautions at workplace:

protective clothing - yes

gloves - essential

arm protectors - recommended when skin contact likely

goggles/safety glasses - yes

Skin protection:

before starting work - Apply barrier cream to exposed skin

after washing - Apply barrier or nourishing cream

Cleansing of contaminated skin:

Dab off with absorbent paper, wash with warm water

and alkali-free soap, then dry with disposable towels.

Do not use solvents

Disposal of spillage:

Soak up with sawdust or cotton waste and deposit in

plastic-lined bin

Ventilation:

of workshop - Renew air 3 to 5 times an hour

of workplaces - Exhaust fans. Operatives should avoid inhaling

vapours

Packaging & Availability

- Regional Availability

Storage & Handling

- Storage and Handling Information

Provided that the product described above is stored in a dry place in its original, properly closed container. At the above mentioned storage temperature it will have the shelf live indicated on the label. The product should not be stored exposed to direct sunlight. Partly emptied containers should be closed immediately after use.

Other

- Appearance

- White powder

- Color (SDS)

- White

- Odor (SDS)

- Odorless

- Chemical Properties

Value Units Test Method / Conditions Hydroxyl Value 3.1 Eq/kg ISO/DIS 4629 - Physical Properties

Value Units Test Method / Conditions Density 1.17-1.19 g/cm³ ISO 8130-3 at 25°C Flash Point min. 215.0 °C ISO 2592 Glass Transition Temperature (Tg) 75.0-85.0 °C Melting Point 150.0 °C