Enhanced TDS

Identification & Functionality

- Chemical Family

- RTU Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Key Properties

Amine-cured laminating system with reactive diluent showing excellent flexibility and high reactivity.

Applications & Uses

- Composites Processing Methods

- Product End Uses

- Markets

- Applications

- Application Information

Industrial composites

Technical Details & Test Data

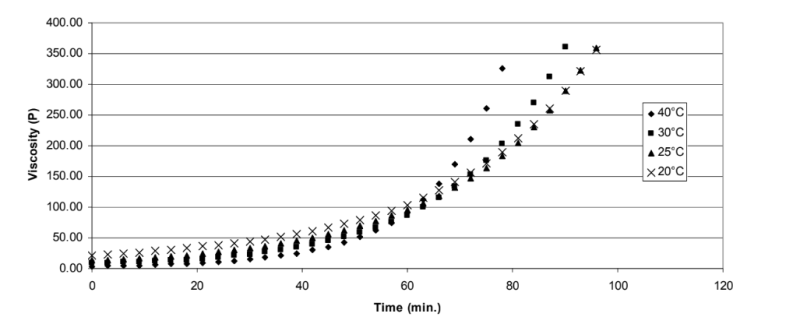

- Viscosity Build Up

VISCOSITY BUILD UP (BROOKFIELD, #6 CONE, 200 RPM)

- Processing Methods

- Filament Winding

- Pressure Moulding

- Resin Transfer Moulding (RTM)

- Wet Lay-up

- Processing Recommendation

Araldite® LY 1556 should be stored in a dry place, in the sealed original container, away from heat and humidity, at temperatures between +2°C and +40°C (+35.6°F and +104°F). The product should not be exposed to direct sunlight. Like many liquid epoxy resins, Araldite® LY 1556 may crystallize when stored below room temperature. Heating the resin to 60-70°C (140-160°F), preferably in a water bath, for several hours, will re-liquify it and restore its original properties. Aradur® 3492 should be stored in a dry place, in the sealed original container, away from heat and humidity, at temperatures between +2°C and +40°C (+35.6°F and +104°F). The product should not be exposed to direct sunlight.

- Cured Properties

Key

Value

Unit

Test Method

Test Condition

Glass Transition Temperature (Tg) 107 - 117 °C IEC 1006, DSC 10 K/MIN, Cure: 3 h at 194°F [90°C]

Tensile strength 9870 - 10,990 psi ISO 527 Cure: 1 h at 110°C

Elongation at tensile strength 3.9 - 6.3 % ISO 527 Cure: 1 h at 110°C

Ultimate strength 9725 - 10,320 psi ISO 527 Cure: 1 h at 110°C

Ultimate elongation 3.9 - 11.4 % ISO 527 Cure: 1 h at 110°C

Tensile modulus 413020 - 422680 psi ISO 527 Cure: 1 h at 110°C

Flexural strength 14,580 - 14,800 psi ISO 178 Cure: 1 h at 110°C

Flexural modulus 385,890 - 390,800 psi ISO 178 Cure: 1 h at 110°C

Fracture toughness K1C 860 - 940 psi/inch PM 258-0/90 Cure: 1 h at 110°C

Fracture energy G1C 1.85 - 2.04 in-lb/inch² PM 258-0/90 Cure: 1 h at 110°C

Safety & Health

- Handling Precautions

Huntsman Advanced Materials Americas LLC maintains up–to-date Material Safety Data Sheets (MSDS) on all of its products. These sheets contain pertinent information that you may need to protect your employees and customers against any known health or safety hazards associated with our products. Users should review the latest MSDS to determine possible health hazards and appropriate precautions to implement prior to using this material.

Other

- Application Information

Value Units Test Method / Conditions Mix Ratio 0.27 %(W) %(W) Hardener : Resin