Enhanced TDS

Identification & Functionality

- Chemical Family

- RTU Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Product Features

- Laminating system with low viscosity and high flexibility.

- The reactivity of this system can be adjusted on demand.

Applications & Uses

- Composites Processing Methods

- Processing Information

- Infusion

- Resin Transfer Moulding

- Wet Lay-up

- Filament Winding

Technical Details & Test Data

- Processing Guidelines

Components Parts by weight Parts by volume Araldite® LY 1568 100 100 Aradur® 3489 28 35 - We recommend that the components are weighed with an accurate balance to prevent mixing inaccuracies which can affect the properties of the matrix system. The components should be mixed thoroughly to ensure homogeneity. It is important that the side and the bottom of the vessel are incorporated into the mixing process.

- When processing large quantities of mixture the pot life will decrease due to exothermic reaction. It is advisable to divide large mixes into several smaller containers.

- Properties of The Cured, Neat Formulation

Property Value Unit Test Method at Condition Glass transition temperature (TG) 142 - 149 °F IEC 1006 Cure: 15 h at 122°F1006, 10 K/min

Glass transition temperature (TG) 167 - 172 °F IEC 1006 Cure: 6 h at 158°F, 10 K/min

Glass transition temperature (TG) 169 - 174 °F IEC 1006 Cure: 4 h at 176°F, 10 K/min

Glass transition temperature (TG) 171 - 176 °F IEC 1006 Cure: 8 h at 176°F, 10 K/min

Glass transition temperature (TG) 174 - 181 °F IEC 1006 Cure: 5 h at 212°F, 10 K/min

Tensile strength 9.7 - 10.3 MPa ISO 527 Cure: 8 h at 176°F

Elongation at tensile strength 4.4 - 5.0 % ISO 527 Cure: 8 h at 176°F

Ultimate strength 7.8 - 8.4 MPa ISO 527 Cure: 8 h at 176°F

Ultimate elongation 10.5 - 11.0 % ISO 527 Cure: 8 h at 176°F

Tensile modulus 413 - 435 MPa ISO 527 Cure: 8 h at 176°F

Flexural strength 17.4 - 18.8 Kpsi ISO 178 Cure: 8 h at 176°F

Elongation at flexural strength 5.5 - 6.5 % ISO 178 Cure: 8 h at 176°F

Ultimate strength 14.5 - 16.6 Kpsi ISO 178 Cure: 8 h at 176°F

Ultimate elongation 9.0 - 10.0 % ISO 178 Cure: 8 h at 176°F

Flexural modulus 61.2 - 63.2 Kpsi ISO 178 Cure: 8 h at 176°F

Fracture toughness (K1C) 636 - 727 psi√inch PM 258-0/90 Cure: 8 h at 80°C

Fracture energy (G1C) 0.84 - 1.06 inch-lb./inch² PM 258-0/90 Cure: 8 h at 80°C

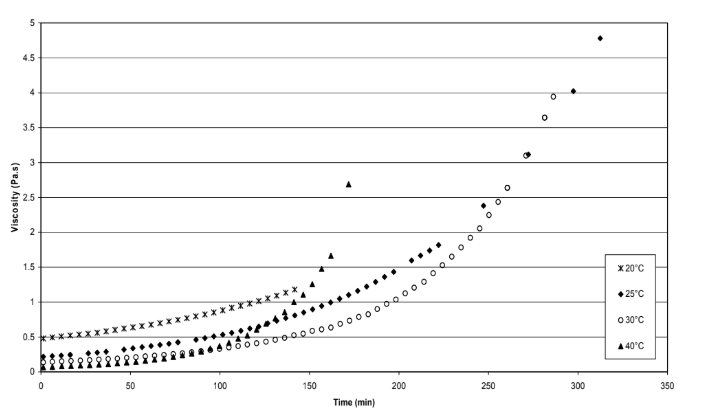

- Viscosity Build Up (Rhemoeter Agr2, Plate/Plate 25 Mm, 100 Rpm)

Storage & Handling

- Storage Conditions

- Araldite® LY 1568 should be stored in a dry place, in the sealed original container, away from heat and humidity, at temperatures between +2°C and +40°C (+35.6°F and +104°F). Under these storage conditions, the shelf life is 5 years. The product should not be exposed to direct sunlight. Partly emptied containers should be closed immediately after use.

- Aradur® 3489 should be stored in a dry place, in the sealed original container, away from heat and humidity, at temperatures between +2°C and +40°C (+35.6°F and +104°F). Under these storage conditions, the shelf life is 3 years. The product should not be exposed to direct sunlight.