Enhanced TDS

Identification & Functionality

- Chemical Family

- RTU Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Product Features

Fast curing epoxy systems with high thermo-mechanical properties and fatigue resistance ideal for the production of composite leaf springs.

Applications & Uses

- Composites Processing Methods

- Product End Uses

- Markets

- Applications

- Processing Information

- Resin Transfer Moulding (low and high pressure)

- Wet Compression Moulding

- Application Information

- Mass production of composite parts able to withstand long-term dynamic loading even under severe hot/wet conditions.

- Production of high thickness composite parts

Technical Details & Test Data

- Processing Information

Processing Guidelines

- We recommend that the components are weighed with an accurate balance to prevent mixing inaccuracies which can affect the properties of the matrix system.

- The components should be mixed thoroughly to ensure homogeneity. It is important that the side and the bottom of the vessel are incorporated into the mixing process.

- When processing large quantities of mixture the pot life will decrease due to exothermic reaction. It is advisable to divide large mixes into several smaller containers. Internal release agent at an amount of 0.5 – 2% is typically added to the system.

- It may either be mixed as a third component or premixed into the Araldite® LY 3585 immediately prior to use. The amount added depends on internal release agent type and part demolding behavior.

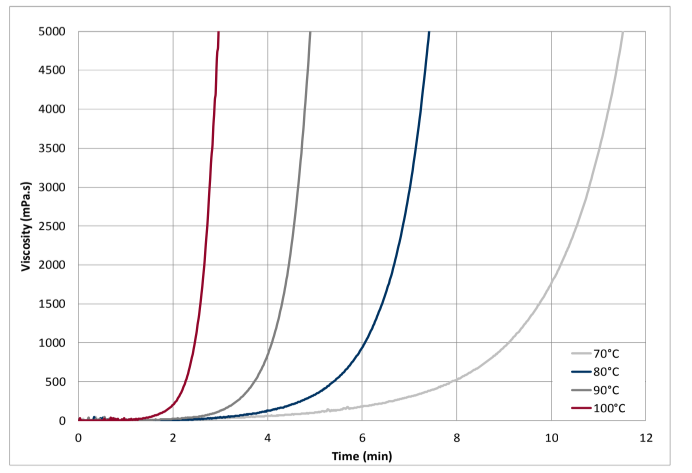

Viscosity Build Up (Brookfield)

Properties of The Cured, Neat Formulation (Thickness 4 mm)

Tensile Modulus 2800 - 2850 MPa ISO 527-2 Tensile Strength 80 - 85 MPa ISO 527-2 Ultimate Elongation 8.0 - 9.0 % ISO 527-2 Flexural Modulus 2800 - 2850 MPa ISO 178 Flexural Strength 125 - 130 MPa ISO 178 Ultimate Elongation 8.5 - 9.5 % ISO 178 Fracture Toughness (K1C) 0.70 - 0.75 MPa√m ISO 13586 Fracture Energy (G1C) 200 - 220 J/m² ISO 13586 - In mold cure - 5min at 100°C

- Oven post-cure - 2h at 140°C

Properties of The Cured, Neat Formulation (Thickness 2 mm)

Glass Transition Temperature (Tg) Onset, at 20 - 200°C 120 - 125 °C ISO 6721, DMA, 5K/MIN Glass Transition Temperature (Tg) Tan δ, at 20 - 200°C 130 - 135 °C ISO 6721, DMA, 5K/MIN - In mold cure - 5min at 100°C

- Oven post-cure - 2h at 140°C

- Viscosity Build Up (Brookfield)

- Properties of The Cured, Neat Formulation (Thickness 2 mm)

Glass Transition Temperature (Tg) Onset, at 20 - 200°C 120 - 125 °C ISO 6721, DMA, 5K/MIN Glass Transition Temperature (Tg) Tan δ, at 20 - 200°C 130 - 135 °C ISO 6721, DMA, 5K/MIN - In mold cure - 5min at 100°C

- Oven post-cure - 2h at 140°C

- Properties of The Cured, Neat Formulation (Thickness 4 mm)

Tensile Modulus 2800 - 2850 MPa ISO 527-2 Tensile Strength 80 - 85 MPa ISO 527-2 Ultimate Elongation 8.0 - 9.0 % ISO 527-2 Flexural Modulus 2800 - 2850 MPa ISO 178 Flexural Strength 125 - 130 MPa ISO 178 Ultimate Elongation 8.5 - 9.5 % ISO 178 Fracture Toughness (K1C) 0.70 - 0.75 MPa√m ISO 13586 Fracture Energy (G1C) 200 - 220 J/m² ISO 13586 - In mold cure - 5min at 100°C

- Oven post-cure - 2h at 140°C

Safety & Health

- First Aid Information

- Contamination of the eyes by resin, hardener or mix should be treated immediately by flushing with clean, running water for 10 to 15 minutes.

- A doctor should then be consulted. Material smeared or splashed on the skin should be dabbed off, and the contaminated area then washed and treated with a cleansing cream (see above).

- A doctor should be consulted in the event of severe irritation or burns.

- Contaminated clothing should be changed immediately. Anyone taken ill after inhaling vapours should be moved out of doors immediately. In all cases of doubt call for medical assistance.

Storage & Handling

- Storage Conditions

- Provided that Araldite® LY 3585 and Aradur® 3835 are stored in a dry place in their original, properly closed containers at the storage temperatures mentioned in the MSDS they will have the shelf lives indicated on the labels.

- Partly emptied containers should be closed immediately after use.

- Araldite® LY 3585 resin may sometimes crystallize during storage, forming a cloudy liquid or solid. It may be restored to its original state by heating to 60 - 80°C until a clear liquid is achieved.

- Handling Information

Protective clothing

Yes Gloves Essential Arm protector Recommended when skin contact likely

Goggestery diasses

Yes Respirator/dust mask

Recommended Skin protection before starting work

Apply barrier cream to exposed skin

Skin protection after washing

Apply barrier or nourishing cream

Skin protection cleansing of contaminated skin

Dab off with absorbent paper, wash with warm water and alkali-free soap, then dry with disposable towels. Do not use solvents

Clean shop requirements

Cover workbenches, etc. with light coloured paper. Use disposable breakers, etc.

Disposal of spillage

Soak up with sawdust or cotton waste and deposit in plastic-lined bin

Ventilation: of workshop

Renew air 3 to 5 times an hour

Ventilation: of workplace

Exhaust fans. Operatives should avoid inhaling vapours.