Enhanced TDS

Identification & Functionality

- Chemical Family

- RTU Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

Applications & Uses

- Composites Processing Methods

- Product Processing Instructions

Resin Transfer Moulding (RTM, SCRIMP, VARTM)

- Mixing Ratio

We recommend that the components are weighed with an accurate balance to prevent mixing inaccuracies which can affect the properties of the matrix system. The components should be mixed thoroughly to ensure homogeneity. It is important that the side and the bottom of the vessel are incorporated into the mixing process. When processing large quantities of mixture the pot life will decrease due to exothermic reaction. It is advisable to divide large mixes into several smaller containers.

Properties

- Notes

Gelation : The values shown are for small amounts of pure resin/hardener mix. In composite structures the gel time can differ significantly from the given values depending on the fibre content and the laminate thickness.

Technical Details & Test Data

- Product Properties

Araldite® LY 8615 / Aradur® 8615 or Hardener XB 5173 epoxy system is a twocomponent, low-viscosity material developed for production of advanced composite parts and moulds using vacuum-assisted resin transfer molding. Composites produced with Araldite® LY 8615 / Aradur® 8615 / XB 5173 epoxy system can achieve a Glass Transition Temperature of over 180°C following appropriate postCure and provide a long pot life.

- Properties of The Cured, Reinforced Formulation

Interlaminar Shear Test (ASTM D 2344)

Cure: 90 min. 80 °C + 1h 150 °C + 1h 180 °C

Property Unit LY 8615 / Aradur® 8615 LY 8615 / XB 5173

Shear strength MPa 72 – 77 74 – 79 Flexural Test – Reinforced Formulation (ISO 178)

Cure: 90 min. 80 °C + 1h 150 °C + 1h 180 °C

Property Unit LY 8615 / Aradur® 8615 LY 8615 / XB 5173

Flexural strength MPa 1260 – 1460 1170 – 1470 Ultimate strength MPa 1150 – 1350 1080 – 1280 Ultimate elongation % 1.00 – 1.20 0.90 – 1.10 Flexural modulus MPa 113500 – 133000 114000 – 134000

Tensile Test – Reinforced Formulation (ISO 527)

Cure: 90 min. 80 °C + 1h 150 °C + 1h 180 °C

Property Unit LY 8615 / Aradur® 8615 LY 8615 / XB 5173

Tensile strength MPa 1360 – 1560 1520 – 1720 Ultimate strength MPa 1290 – 1490 1450 – 1650 Ultimate elongation % 0.9 – 1.3 1.1 – 1.4 Tensile modulus MPa 120500 – 140000 129000 – 144000

- Properties of The Cured, Neat Formulation

Glass Transition Temperature (IEC 1006, DSC, 10 K/min)

Cure Condition Unit Araldite® LY 8615 / Aradur® 8615 Araldite® LY 8615 / XB 5173

90 min. 80 °C °C 64 – 71 80 – 84 90 min. 80 °C + 1h 150 °C °C 184 – 194 174 – 181 90 min. 80 °C + 1h 150 °C + 1h 180 °C °C 206 – 212 197 – 202 90 min. 80 °C + 1h 150 °C + 3h 180 °C °C 210 – 220 203 – 210 Glass Transition Temperature (ISO 6721, DMA, 2K/min)

Cure Condition Unit Araldite® LY 8615 / Aradur® 8615 Araldite® LY 8615 / XB 5173

90 min. 80 °C + 1h 150 °C °C 184 – 190 207 – 215 90 min. 80 °C + 1h 150 °C + 1h 180 °C °C 214 – 221 210 – 217 Tensile Test (ISO 527)

Cure: 90 min. 80 °C + 1h 150 °C

Property Unit Araldite® LY 8615 / Aradur® 8615 Araldite® LY 8615 / XB 5173

Tensile strength MPa 40 – 45 33 – 38 Ultimate elongation % 1.5 – 2.3 1.0 – 1.5 Tensile modulus MPa 2650 – 2850 2880 – 3080 Tensile Test (ISO 527)

Cure: 90 min. 80 °C + 1h 150 °C + 1h 180 °C

Property Unit Araldite® LY 8615 / Aradur® 8615 Araldite® LY 8615 / XB 5173

Tensile strength MPa 39 – 43 41 – 45 Ultimate elongation % 1.2 – 2.2 1.2 – 2.2 Tensile modulus MPa 2780 – 2980 3000 – 3200 Flexural Test (ISO 178)

Cure: 90 min. 80 °C + 1h 150 °C

Property Unit LY 8615 / Aradur® 8615 LY 8615 / XB 5173

Flexural strength MPa 92 – 97 115 – 125 Ultimate elongation % 3.1 – 4.5 4.9 – 5.9 Flexural modulus MPa 2650 – 2850 2850 – 3050 Flexural Test (ISO 178)

Cure: 90 min. 80 °C + 1h 150 °C + 1h 180 °C

Property Unit LY 8615 / Aradur® 8615 LY 8615 / XB 5173

Flexural strength MPa 82 – 86 113 – 117 Ultimate elongation % 2.7 – 3.7 4.1 – 5.1 Flexural modulus MPa 2740 – 2940 3008 – 3280 Fracture Properties – Bend Notch Test (PM 258-0/90)

Cure: 90 min. 80 °C + 1h 150 °C

Property Unit LY 8615 / Aradur® 8615 LY 8615 / XB 5173

Fracture toughness K₁C MPa√m 0.57 – 0.72 0.60 – 0.84 Fracture energy G₁C J/m² 140 – 170 147 – 179 Fracture Properties – Bend Notch Test (PM 258-0/90)

Cure: 90 min. 80 °C + 1h 150 °C + 1h 180 °C

Property Unit LY 8615 / Aradur® 8615 LY 8615 / XB 5173

Fracture toughness K₁C MPa√m 0.59 – 0.74 0.54 – 0.70 Fracture energy G₁C J/m² 130 – 165 130 – 165 Water Absorption (ISO 62)

Cure: 90 min. 80 °C + 1h 150 °C

Condition Unit LY 8615 / Aradur® 8615 LY 8615 / XB 5173

10 days H₂O at 23 °C % 0.50 – 0.60 0.53 – 0.63 Water Absorption (ISO 62)

Cure: 90 min. 80 °C + 1h 150 °C + 1h 180 °C

Condition Unit LY 8615 / Aradur® 8615 LY 8615 / XB 5173

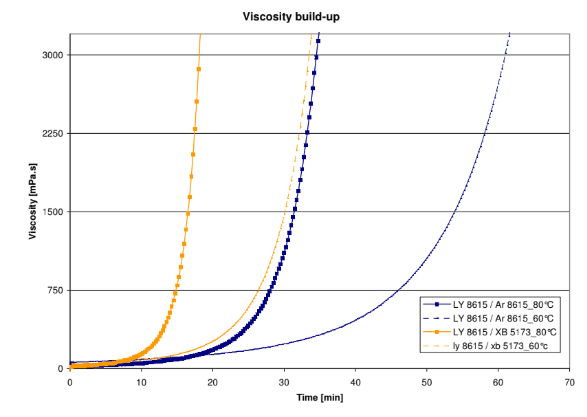

10 days H₂O at 23 °C % 0.55 – 0.65 0.55 – 0.65 - Viscosity Build Up

Safety & Health

- Handling Precautions

Personal hygiene Safety precautions at workplace protective clothing overalls gloves essential arm protectors recommended when skin contact likely goggles/safety glasses yes Skin protection before starting work Apply barrier cream to exposed skin after washing Apply barrier or nourishing cream Cleansing of contaminated skin Dab off with absorbent paper, wash with warm water

and alkali-free soap, then dry with disposable towels.

Do not use solventsDisposal of spillage Soak up with sawdust or cotton waste and deposit in

plastic-lined binVentilation of workshop Renew air 3 to 5 times an hour Ventilation of workplaces Exhaust fans. Operatives should avoid inhaling

vapoursFirst Aid : Contamination of the eyes by resin, hardener or mix should be treated immediately by flushing with clean, running water for 10 to 15 minutes. A doctor should then be consulted. Material smeared or splashed on the skin should be dabbed off, and the contaminated area then washed and treated with a cleansing cream (see above). A doctor should be consulted in the event of severe irritation or burns. Contaminated clothing should be changed immediately. Anyone taken ill after inhaling vapours should be moved out of doors immediately. In all cases of doubt call for medical assistance.

Storage & Handling

- Storage Conditions

Provided that Araldite® LY 564, Araldite® LY 3585 or Hardener XB 3458 are stored in a dry place in their original, properly closed containers at the storage temperatures mentioned in the MSDS they will have the shelf lives indicated on the labels. Partly emptied containers should be closed immediately after use. Araldite® LY 3585 which has crystallized and looks cloudy can be restored to its original state by heating to 60 - 80°C.

Other

- Application Information

Value Units Test Method / Conditions Mix Ratio 0.5 %(W) Hardener (ARADUR® 8615) : Resin Mix Ratio 0.38 %(W) Hardener (HARDENER XB 5173) : Resin