Enhanced TDS

Identification & Functionality

- Blend

- No

- CASE Ingredients Functions

- Chemical Family

- Composite Materials Functions

- Function

- Resins, Binders & Matrix Materials,Binder & Resin

- Polymer Name

- Single Ingredient

- Yes

- Technologies

- Product Families

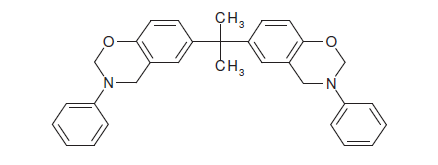

- Chemical Structure

Features & Benefits

- CASE Ingredients Features

- Materials Features

Applications & Uses

- Adhesive & Sealant End Applications

- Compatible Polymers & Resins

- Composites End Use

- Composites Processing Methods

- Markets

- Applications

Properties

- Physical Form

Regulatory & Compliance

- Chemical Inventories

Technical Details & Test Data

- Cast Procedure

Weigh benzoxazine material in an appropriate kettle equipped with heating capability, mechanical stirrer and temperature recording device. Heat with continuous stirring to 120 - 140°C until a clear homogeneous solution is obtained. Additional heating dictates the pot life of the resultant prepolymer. For clear casting, degas the resultant mixture, while maintained at 120°C - 140°C, at 26+ inches of vacuum for 15 minutes; or until foaming has stopped. This indicates that the product has been purged of any volatiles. Hot degassed melt can be poured into preheated molds; and cured at the desired conditions.

Packaging & Availability

- Regional Availability

Storage & Handling

- Storage and Handling Information

Araldite® MT35600 benzoxazine resin should be stored in a dry place, preferably in the sealed original container, at temperatures between 2 and 40 °C. The product should not be stored exposed to direct sunlight.

Other

- Appearance

- Yellowish solid

- Color (SDS)

- Yellow

- Odor (SDS)

- Odorless

- Mechanical Properties

Value Units Test Method / Conditions Flexural Strength 122.0 MPa ISO 178/01 cure schedule: 2h at 180°C + 2h at 200°C Tensile Strength 59.0 MPa ISO 527 T2/93 cure schedule: 2h at 180°C + 2h at 200°C - Physical Properties

Value Units Test Method / Conditions Flash Point min. 100.0 °C Pensky-Martens Closed Cup (PMCC) Flash Point min. 100.0 °C Closed Cup Flash Point min. 100.0 °C ISO 2719 Gel Time 250.0-550.0 s ISO 8130-6 at 220°C Glass Transition Temperature (Tg) 160.0-170.0 °C Differential Scanning Calorimetry ramp at 10°C/30°C-300°C/nitrogen Glass Transition Temperature (Tg) 170.0-180.0 °C Dynamic Mechanical Analysis (DMA) ramp at 10°C/30°C – 300°C/nitrogen Melting Point 60.0-80.0 °C Melting Point 58.0-70.0 °C Internal Method Viscosity 50.0-500.0 mPa.s ISO 3219 at 125°C