Enhanced TDS

Identification & Functionality

- Blend

- No

- CASE Ingredients Functions

- Chemical Family

- Composite Materials Functions

- Function

- Resin Modifier, Binder, Resin, Resins, Binders & Matrix Materials

- Plastics & Elastomers Functions

- Single Ingredient

- Yes

- Technologies

- Product Families

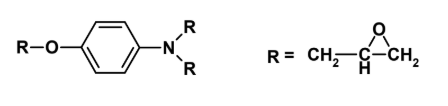

- Chemical Structure

Features & Benefits

- CASE Ingredients Features

- Product Features

- Low viscosity

- Fast reacting

- Excellent chemical resistance

- Good mechanical strength

- Excellent thermal properties

- Outstanding corrosion resistance

Applications & Uses

- Application Area

- Composites End Use

- Plastics & Elastomers End Uses

- Markets

- Applications

Properties

- Physical Form

Regulatory & Compliance

Technical Details & Test Data

- Formulations

Araldite® MY 0510 is a particularly effective resin in a wide variety of formulating applications including adhesives, laminating systems, etc. It can be used as a viscosity modifier and also with slow reactivity resins to boost their rate of cure; however, caution must be exercised in the selection of hardeners and cure conditions because of its rapid cure characteristics. Even moderate amounts, when cured with aliphatic amines, can develop sufficient exotherm to cause charring and smoke evolution. This can also occur if aromatic amine hardened systems are gelled at excessively high temperatures or if catalysts, such as boron trifluoride monoethylamine, are used alone or in conjunction with aromatic

Formulation Parts by weight MY 0510 100 100 Aradur® 976-1 49 - Aradur® 5200 - 45 Gel time, min. 42.2 at 160°C 94.3 at 120°C 18.9 at 180°C 24.8 at 150°C 8.2 at 200°C 8.4 at 180°C Cure schedule 0.5hr/80°C 2hrs/150°C 0.5hr/100°C 2hrs/200°C 1.5hr/120°C 2hr/177°C Glass Transition Temperature DMA (DRY) (°C) 270 252 DMA (WET1) (°C) 184 183 Water absorbance² (%) 2.8 4.8 Flexural test at 25°C Modulus, ksi (GPa) 501 (3.4) 467 (3.2) Strength, ksi (MPa) 20 (137) 16.5 (113) Tensile test at 25°C Modulus, ksi (GPa) 515 (3.5) 455 (3.1) Strength, ksi (MPa) 10.4 (71.1) 10.8 (73.8) Elongation, % 2.7 3.6 Tensile test at 100°C Modulus, ksi (GPa) 336 (2.3) 266 (1.8) Strength, ksi (MPa) 7.4 (50.5) 5.7 (39) Elongation, % 2.5 2.4

Packaging & Availability

- Regional Availability

Storage & Handling

- Storage Information

- Araldite® MY 0510 comes in a 55 gallon, non-returnable, closed-head, black iron drum (DOT 17E) containing 500 pounds. This product should be stored in a dry place, in the sealed original container, at temperatures between +2C and +8C (+35.6°F and 46.4°F ). Under these storage conditions, the shelf life is 3 years. The product should not be exposed to direct sunlight.

- Never store Araldite® MY 0510 in warm areas near heat sources or hot equipment, or even in direct sunlight, because violent exothermic reaction or explosion may result.

- Storage at higher temperatures may adversely affect properties. Maximum temperatures this product should be subjected to while thawing for use should not exceed 37 8C (100°F). To facilitate handling of Araldite MY 0510 as a workable liquid, warm the container gradually by letting it stand in an area at room temperature approximately 23.9°C ( 75°F) prior to use. Never accelerate warming by using hot ovens, band heaters, hot plates, open flames, or any means which could cause a "hot spot." Such practices may initiate violent exothermic reaction or explosion. Contamination, especially by acidic or basic substances, may also start a violent exothermic reaction and must be avoided.

Other

- Appearance

- Clear, no contamination

- Physical Properties

Value Units Test Method / Conditions Density 1.21-1.22 g/cm³ g/cm³ at 25°C Flash Point min. 93.0 °C °C Closed Cup Viscosity 550.0-850.0 mPa.s mPa.s at 25°C