Enhanced TDS

Identification & Functionality

- Blend

- No

- Chemical Family

- Composite Materials Functions

- Function

- Resins, Binders & Matrix Materials

- Single Ingredient

- Yes

- Technologies

- Product Families

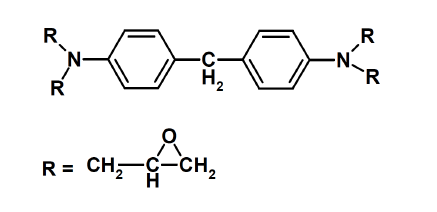

- Chemical Structure

Features & Benefits

- Materials Features

- Features

- Low viscosity for processing temperature

- Exceptionally long pot life

- Excellent wet-out of reinforcements

- Exceptionally good long-term, high-temperature performance

- Low moisture uptake

- Outstanding hot-wet performance

- Exceptional chemical and heat resistance

- Extremely high glass transition temperatures

- Excellent retention of modulus at elevated temperatures

- Good electrical properties

- Extremely low shrinkage

- Individual components are room temperature stable

Applications & Uses

- Application Area

- Composites Processing Methods

- Markets

- Applications

- Processing

Carefully heat the ARALDITE® MY 721 resin to 50°C and slowly stir in the ARADUR® 5200 hardener until a clear homogenous solution is obtained. For a clear casting, maintain a temperature between 40°C and 50°C and degas for 15 minutes at 30 inches of mercury. Then pour the material into the molds and cure according to the cure schedule listed below.

Properties

- Physical Form

Regulatory & Compliance

Packaging & Availability

- Regional Availability

Storage & Handling

- Storage and Handling Information

ARALDITE® MY 721 Resin is available in 145, 450, and 500 pound metal drums. The product should be stored in a dry place, in the sealed original container, away from heat and humidity, at temperatures between 2°C and 8°C (35.6°F and 46.4°F). Under these storage conditions, the shelf life is 2 years (from date of manufacture). The product should not be exposed to direct sunlight.

Other

- Appearance

- Clear brown liquid

- Color (SDS)

- Brown

- Odor (SDS)

- Slight

- Chemical Properties

Value Units Test Method / Conditions Epoxy Equivalent Weight 111.0-117.0 g/eq - Electrical Properties

Value Units Test Method / Conditions Dielectric Strength 440.0 V/mil - Mechanical Properties

Value Units Test Method / Conditions Flexural Strength 14.9 ksi Tensile Strength 8.7 ksi - Physical Properties

Value Units Test Method / Conditions Density 1.15-1.18 g/cm³ at 25°C Glass Transition Temperature (Tg) 237.0 °C Differential Scanning Calorimetry samples cured 2h at 150°C + 2h at 180°C, dry Glass Transition Temperature (Tg) 231.0 °C Differential Scanning Calorimetry samples cured 2h at 150°C + 2h at 180°C, wet Glass Transition Temperature (Tg) 214.0 °C Thermomechanical Analyzer samples cured 2h at 150°C + 2h at 180°C Viscosity 3000.0-6000.0 cPs at 50°C