Enhanced TDS

Identification & Functionality

- Chemical Family

- RTU Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

Applications & Uses

- Composites Processing Methods

- Product End Uses

Properties

- Physical Form

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

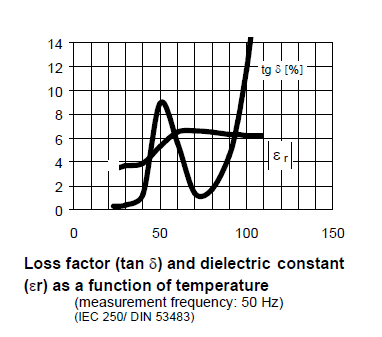

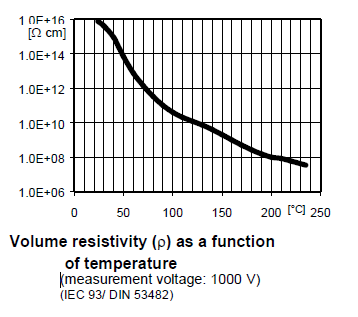

- Electrical Properties

System: ARALDITE® MY 750 100 pbw

HARDENER HY 5922 55 pbw

Determined on standard test specimen at 23°C

Curing Cycle: 6h at 40°C + 3h at 80°CBreakdown strength IEC 60243-1 kV/mm 25 - 30 Loss factor tan δ > 1% IEC 250/ DIN 53483 % 35 - 40 Loss factor tan δ > 5% IEC 250/ DIN 53483 % 40 - 45 Dielectric constant εr at 25℃ IEC 250/ DIN 53483 3.7 Volume resistivity at 25℃ IEC 93/ DIN 53482 ohm.cm 7.70E + 15

- Processing Information

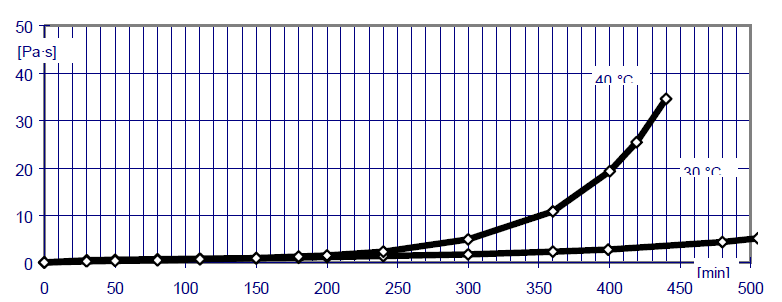

System: Araldite MY 750’ 100 pbw

Hardener HY 5922 55 pbwProcessing Viscosity

Fig.3.1: Viscosity increase at 30 and 40°C in function of the time

(measurements with Rheomat 115A, MS DIN 125, D =10 s-1)Viscosity increase at:

30°C - 4h 30 min

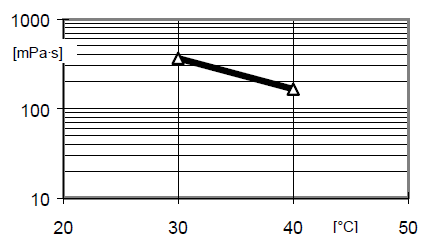

40°C - 3h 25 minFig.3.2: Viscosity increase at 30 and 40°C as a function of the time (measurements with Rheomat 115A, MS DIN 125, D =10 s-1)

Fig.3.3: Initial viscosity as a function of temperature

(measurements with Rheomat 115A, MS DIN 125, D =10 s-1)

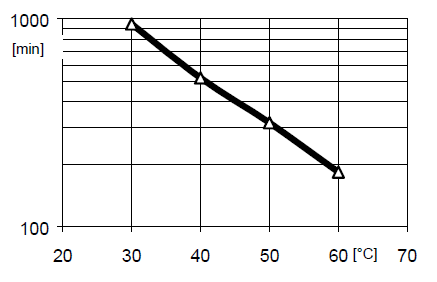

Fig.3.4: Geltime as a function of temperature (measured with Gelnorm Instrument, ISO 9396)

Mechanical and Physical properties

System: ARALDITE® MY 750 100 pbw HARDENER HY 5922 55 pbw Determined on standard test specimen at 23°C Curing Cycle: 6h at 40°C + 3h at 80°C Flexural strength ISO 178 MPa 95 - 105 Surface strain ISO 178 % 3.5 - 4.5 E modulus from flexural strength ISO 178 MPa 2700 - 3100 Tensile strength ISO R 527 MPa 55 - 65 Elongation at break ISO R 527 % 6 - 9 E modulus from tensile strength ISO R 527 MPa 2800 - 3200 Impact strength ISO 179 kJ/m² 60 - 70 Glass transition temperature (DSC) IEC 1006 °C 43 - 55 Heat Distortion Temperature ISO 75 °C 45 - 55 Bend Notch Critical Stress Intensity Factor Kic ISO/ DIN 1358 MPa.m1/2 0.95 - 1.0 Specific Energy at break Gic IEC 1006 °C 300 - 360 Test performed with plastic deformation precracking only: Critical Stress Intensity Factor Kic CG 216-0/89 MPa.m1/2 3.0 - 3.2 Specific Energy at break Gic J/m² 3300 - 3600 Water absorption (specimen: 50x50x4 mm) ISO 62 4 days at 23°C % 0.35 - 0.45 10 days at 23°C % 0.55 - 0.65 Storage under tropical conditions after 10 days at 40°C / 92% rel. humidity CG 75 % 1.1 - 1.4 - Mechanical & Physical Properties

System: Araldite MY 750' 100 pbw Hardener HY 5922 55 pbw Determined on standard test specimen at 23°C Curing Cycle: 6h at 40°C + 3h at 80°C Flexural strength ISO 178 MPa 95 - 105 Surface strain ISO 178 % 3.5 - 4.5 E modulus from flexural strength ISO 178 MPa 2700 - 3100 Tensile strength ISO R 527 MPa 55 - 65 Elongation at break ISO R 527 % 6 - 9 E modulus from tensile strength ISO R 527 MPa 2800 - 3200 Impact strength ISO 179 kJ/m² 60 - 70 Glass transition temperature (DSC) IEC 1006 °C 43 - 55 Heat Distortion Temperature ISO 75 °C 45 - 55 Bend Notch Critical Stress Intensity Factor Kic ISO/ DIN 1358 MPa.m1/2 0.95 - 1.0 Specific Energy at break Gic IEC 1006 °C 300 - 360 Test performed with plastic deformation precracking only: Critical Stress Intensity Factor Kic CG 216-0/89 MPa.m1/2 3.0 - 3.2 Specific Energy at break Gic J/m² 3300 - 3600 Water absorption (specimen: 50x50x4 mm) ISO 62 4 days at 23°C % 0.35 - 0.45 10 days at 23°C % 0.55 - 0.65 Storage under tropical conditions after 10 days at 40°C / 92% rel. humidity CG 75 % 1.1 - 1.4

Storage & Handling

- Storage Conditions

- Store the components in a dry place in tightly sealed original containers.

- Under these conditions, the shelf life will correspond to the expiry date stated on the label.

- Partly emptied containers should be tightly closed immediately after use.

Other

- Application Information

Value Units Test Method / Conditions Mix Ratio 0.55 %(W) %(W) Hardener : Resin