Enhanced TDS

Identification & Functionality

- Chemical Family

- RTU Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Product Properties

- Very good thermal shock resistance

- Very good thermal endurance

- Flammability : UL 94 approval V0 for 4 mm thick layer

Applications & Uses

- Composites Processing Methods

- Product End Uses

- Markets

- Applications

Technical Details & Test Data

- Processing Information

Processing Information

- The ARALDITE resin component should be stirred and homogenized in the original container before use.

- The ARALDITE casting mix is best prepared by heating the ARALDITE resin up to 40- 50°C before stirring in the hardener.

- Brief degassing of the mix under 5-10 mbar vacuum improves the mixture homogeneity and enhances the dielectric properties of the castings.

Mix Ratio and Processing data

Property Condition Unit Value Mix Ratio - pbw 100 : 12 Initial Mix Viscosity 25°C mPa·s ca. 3,900 Initial Mix Viscosity 45°C mPa·s ca. 780 Gel Time (Gelnorm) 60°C min ca. 16 Mechanical and Physical properties

Determined on standard test specimens at 23°C, cured for 24 h/RT + 6 h/60°C

Color of castings Green Specific gravity at 25°C DIN 55990 g/cm³ ca. 1.63 Shore D hardness (4 mm plate) at 25°C DIN 53505 ca. 90 Tensile strength at 25°C ISO 527T2/93 MPa ca. 56 Elongation at break at 25°C ISO 527T2/93 % ca. 1.1 E modulus at 25°C ISO 527T2/93 MPa ca. 8450 Glass transition temperature TA STAR °C ca. 58 Coefficient of linear thermal expansion DIN 53 752/80 ppm/K ca. 52.25 Thermal conductivity ISO 8894/90 W/mK ca. 0.78 Water absorption 1 day at 23°C ISO 63/80 % ca. 0.08 30 min at 100°C ISO 62/80 % ca. 0.4 Electric strength 2 mm plate at 23°C IEC 243-1 kV/mm ca. 25 Flammability UL 94 V-0 4 mm Note: To determine whether cross-linking has been carried to completion and the final properties are optimal, it is necessary to carry out relevant measurements on the actual object or to measure the glass transition temperature. Different gelling and cure cycles in the customer’s manufacturing process could lead to a different degree of cross linking and thus a different glass transition temperature.

System tested:

ARALDITE® XB 5720 / ARALDITE® XB 5729

Mix ratio: 100 / 12 pbw

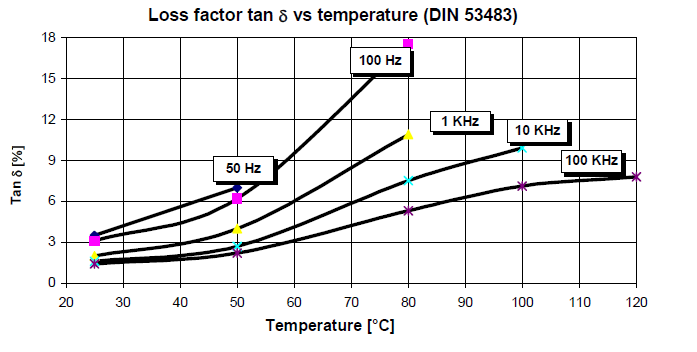

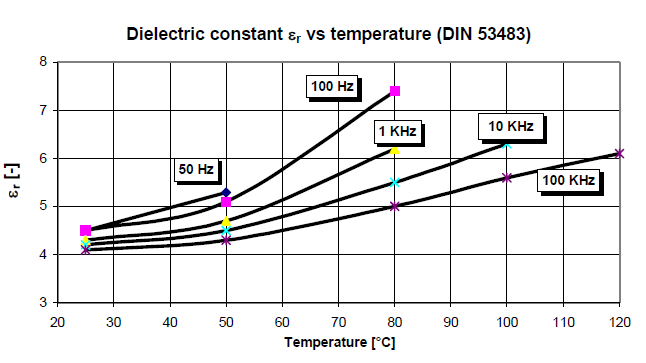

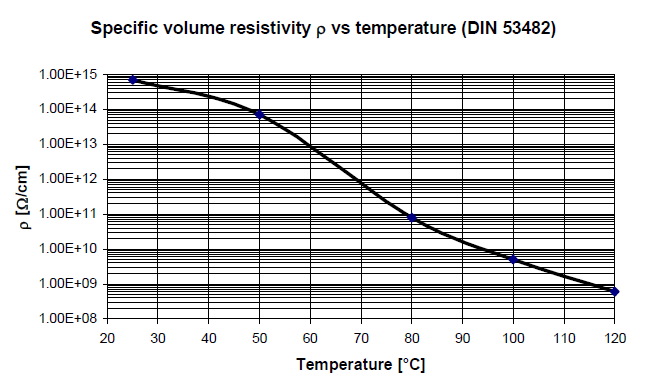

Guideline values determined on standard test specimens cured for 24 h/ RT + 6 h/60°CElectrical Properties

Processing methods: Atmospheric or Vacuum casting

Storage & Handling

- Storage and Handling Information

- Regular procedures approved by national and/or local authorities

- Store the components in a dry place at 18-25°C, in tightly sealed original containers.

- Under these conditions, the shelf life will correspond to the expiry date stated on the label.

- After this date, the product may be processed only after reanalysis.

- Partly emptied containers should be tightly closed immediately after use.

- Disposal: Regular procedures approvedand/or local authorities

Other

- Application Information

Value Units Test Method / Conditions Mix Ratio 0.12 %(W) Hardener : Resin