Enhanced TDS

Identification & Functionality

- Blend

- No

- Chemical Family

- Polymer Name

- Single Ingredient

- Yes

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Materials Features

- Product Advantages

Hard wearing outsoles:

- Density range 1.2 down to 0.7 kg/m3 depending on design

- Rubber-like grip and feel

- Non-floor marking

- Excellent abrasion resistance

- Good surface definition

- Improved sole flexibility (Bata belt / Bennewardt).

Lightweight comfortable midsole:

- Better cushioning

- Multiple colors possible (fashion oriented).

Productivity:

Compatible with standard polyurethane injection and casting machines; cumbersome stick on processes can be avoided.

Applications & Uses

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

Technical Details & Test Data

- Technical Data

- Typical Technical Properties

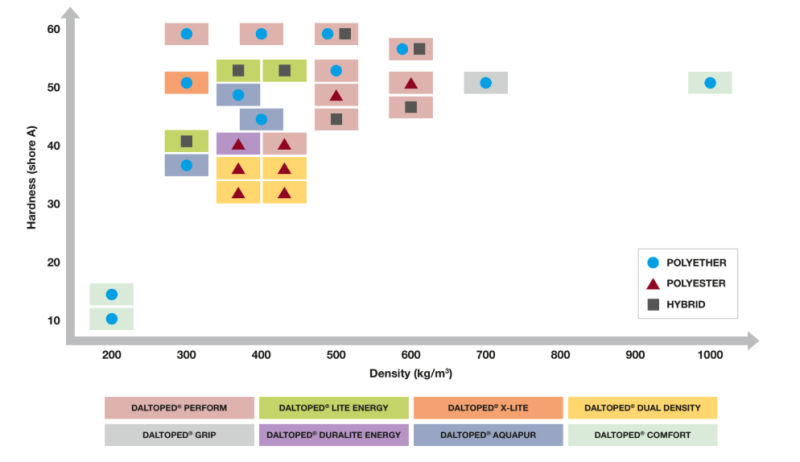

Polyether DALTOPED® DUAL DENSITY*

Outsole Outsole Midsole Midsole Density (kg/m3) 1000 kg/m3 800 kg/m3 450 kg/m3 300 kg/m3 Hardness (Shore A) 60 50 45 40 Trouser tear (N/mm) 9.0 8.5 5.5 4.0 Tensile strength (MPa) 5.5 5.0 3.0 2.0 Elongation (%) 450 400 350 300 Flex life Bennewardt 30 / 60 kcycl 0-0-0 0-0-0 N/a N/a Abrasion (mg loss) 40-80 60-100 N/a N/a *DALTOPED® DUAL DENSITY system based on polyether technology

Polyester DALTOPED® DUAL DENSITY*

Outsole Outsole Midsole Midsole Density (kg/m3) 1200 kg/m3 800 kg/m3 450 kg/m3 400 kg/m3 Hardness (Shore A) 65 55 45 40 Trouser tear (N/mm) 12.0 10.0 6.0 5.0 Tensile strength (MPa) 9.5 8.0 4.0 3.0 Elongation (%) 600 550 400 350 Flex life Bennewardt 30 / 60 kcycl 0-0-0 0-0-0 N/a N/a Abrasion (mg loss) 40-80 60-100 N/a N/a * DALTOPED® DUAL DENSITY system based on polyester technology