Enhanced TDS

Identification & Functionality

- Blend

- No

- Chemical Family

- Polymer Name

- Single Ingredient

- Yes

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Materials Features

- Performance Benefits

- Lightweight

- Cushioning effect

- High resilience

- Cold temperature resistant

- Hydrolysis resistant

- Good compression set

- Abrasion resistant

- Multiple color possibilities

- Suitable for PU/PU, PU/TPU, PU/VR

- Outstanding flow for design flexibility

- Cost benefits

- No additional investment required (suitable for processing on conventional polyurethane machinery)

- Low density

- Low scrap rate because of good flow and mold filling

- Lower energy consumption and assembling costs (compared to EVA)

- Processing Benefits

- Excellent flow

- Good blend stability in machine tanks

- Compatible with all existing and evolving shoe manufacturing techniques such as automation, speed, spraying, casting, etc. ...

- Excellent physical properties compared to EVA

- Production flexibility as one system can be used for both midsole and single density

- Product Feature

- High rebound and cushioning

- Excellent physical properties compared to EVA

Applications & Uses

- Compatible Polymers & Resins

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Markets

- Applications

Technical Details & Test Data

- Technical Data

Other

- Mechanical Properties

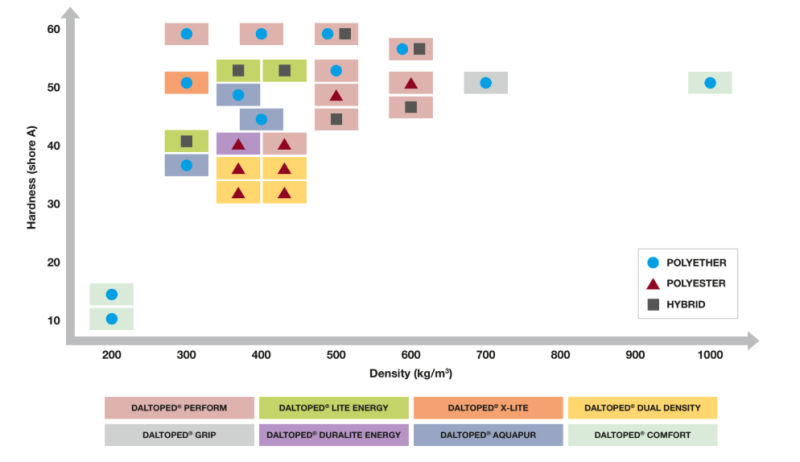

Value Units Test Method / Conditions Compression Set max. 10.0 - at room temperature, Midsoles Compression Set max. 10.0 - Unitsoles, at RT Elongation min. 300.0 - of Midsoles Elongation 340.0 - of Unitsoles Hardness 30.0-40.0 - Midsoles, tailor made Hardness 35.0-45.0 - Unitsoles, tailor made Tensile Strength 2.5-3.0 MPa MPa Midsoles Tensile Strength 2.5-3.5 MPa MPa Unitsoles - Physical Properties

Value Units Test Method / Conditions Density 350.0-450.0 - Midsoles Density 450.0-500.0 - Unitsoles