Enhanced TDS

Identification & Functionality

- Chemical Family

- Technologies

- Product Families

Features & Benefits

- Industrial Additives Features

- Labeling Claims

- Product Advantages

- Improved flexibility: The polyether backbone gives the product excellent flexibility.

- Improve hydrophilicity, polarity and antistatic properties: The polyether backbone imparts hydrophilicity, polarity and antistatic properties to the product.

- Versatility: Can be used with various types of nylon – such as nylon 6, nylon 66 and long chain nylons (nylon 12, nylon 610 and nylon 612 etc.

- Higher reactivity: The terminal amino group is more reactive than the hydroxyl group, and no catalyst is required for the polycondensation reaction, making the operation simple.

Applications & Uses

- Applicable Processes

- Compatible Substrates & Surfaces

- Industrial Additives End Use

- Markets

- Applications

Properties

- Physical Form

- Soluble In

- Use Ratio

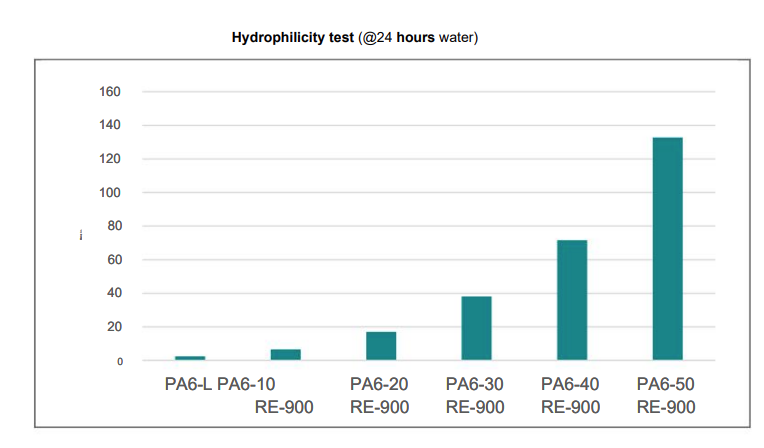

- When ELASTAMINE® RE-900 polyetheramine is copolymerized with lactam or nylon salt and dicarboxylic acid, in order to give the polyamide a certain hydrophilicity and flexibility, the recommended initial use amount is 20% of the total weight of the copolymer.

- The actual amount of polyetheramine should be adjusted according to the required elasticity and balance of other properties.

Regulatory & Compliance

Technical Details & Test Data

- Formulation Guide

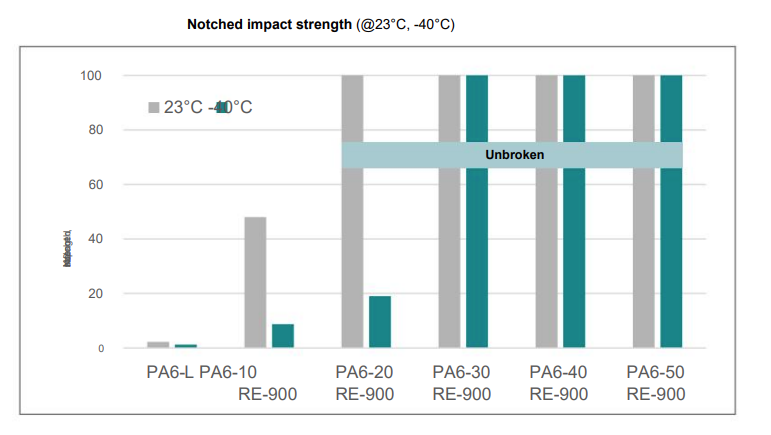

- ELASTAMINE® RE-900 polyetheramine can be used to improve the hydrophilicity and mechanical properties of polyamides. In a typical application case, ELASTAMINE® RE-900 polyetheramine can react with lactam or nylon salt and dicarboxylic acid to form polyether block polyamide copolymers. The polyether soft segment can improve the hydrophilicity, flexibility and polarity of polyamides.

ELASTAMINE® RE-900 polyetheramine improves hydrophilicity.

ELASTAMINE® RE-900 polyetheramine improves low temperature performance and impact resistance

Packaging & Availability

- Regional Availability

Storage & Handling

- Storage Information

- ELASTAMINE® RE-900 polyetheramine can be stored in air at room temperature for a considerable period of time, but we generally recommend storing it under nitrogen to reduce the risk of accidental exposure to high temperatures and reduce the product's absorption of water vapor and carbon dioxide in the air. It should be noted that as long as the temperature exceeds 140°F (60°C), even with gas protection, discoloration may occur.

- Equipment and pipes contaminated with ELASTAMINE® RE-900 can be cleaned with warm water and steam . In the event of an accidental spill, the area should be flushed with large amounts of water. The proper method of waste disposal is incineration in accordance with relevant federal, state or local regulations.

Other

- Appearance (SDS)

- Liquid

- Color (SDS)

- Light yellow