Enhanced TDS

Identification & Functionality

- Chemical Family

- RTU Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Product Features

- Exceptionally high temperature resistance.

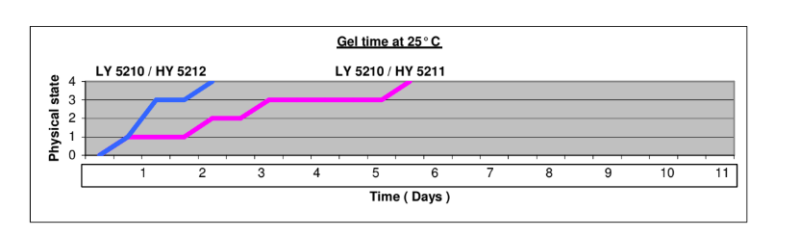

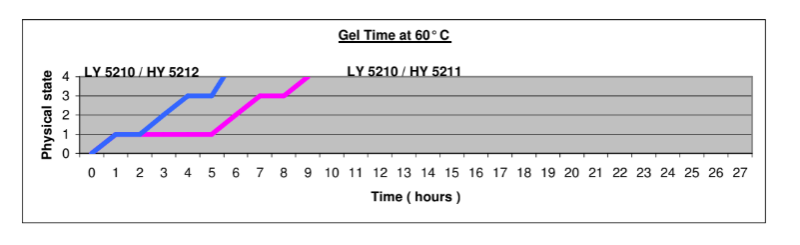

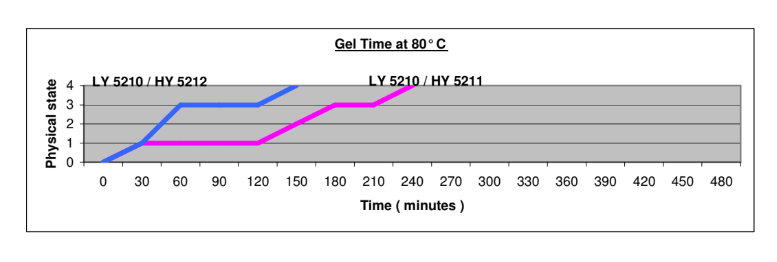

- Variable speed of cure control.

- Excellent fiber wet-out properties due to low viscosities.

- Partial cure at room temperature completed with indicated post cure.

- Excellent inter layer adhesion.

Applications & Uses

- Compatible Substrates & Surfaces

- Composites Processing Methods

- Product End Uses

- Markets

- Applications

- Application Information

- Extremely large tools can be produced due to very long pot life.

- Tools requiring heat resistance up to 200° C.

- Fast and medium hardeners allow better control over reaction.

- For heat resistant tools used with glass or carbon fibers.

- Pre-preg lay-up tools.

Properties

- Physical Form

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Processing Information

Processing

Mix Ratio

Parts by Weight

RenLam® LY 5210 100 Ren® HY 5212 40 Mix the two components thoroughly in the ratio indicated, then impregnate each layer of cloth as it is laid up to construct the laminate. Post-curing is essential to benefit the final properties.

After Cure

24 hours RT+ 12 hours at 40 °C + 2 hours at 80 °C + 2 hours at 100°C + 2 hours at 120°C + 2 hours at 140°C + 2 hours at 160 °C + 2 hours at 180 °C + 12 hours at 200 °C and slowly cooled down to RT

Density ISO 1183 g/cm³ 1.1 1.1 Hardness ISO 868 Shore 85 D 85 D Flexural Strength ISO 178 MPa 110 88 Flexural Modulus ISO 178 MPa 3300 3500 Compressive Strength ISO 604 MPa 130 153 Deflection Temperature ISO 75 °C 190 190 Glass Transition Temperature DSC °C 200 200 Impact Strength Charpy KJ/m² 2.5 3

Safety & Health

- Handling Information

Our products are generally quite harmless to handle provided that certain precautions normally taken when handling chemicals are observed. The uncuredmaterials must not, for instance, be allowed to come into contact with foodstuffs or food utensils, and measures should be taken to prevent the uncured materials from coming in contact with the skin, since people with particularly sensitive skin may be affected. The wearing of impervious rubber or plastic gloves will normally be necessary; likewise the use of eye protection. The skin should be thoroughly cleansed at the end of each working period by washing with soap and warm water.The use of solvents is to be avoided. Disposable paper - not cloth towels - should be used to dry the skin. Adequate ventilation of the working area is recommended.

Packaging & Availability

- Packaging Information

System RenLam® LY 5210 Ren® HY 5212 Quantity and Weight 25 kg 20 kg Quantity and Weight 1000 kg 165 kg

Storage & Handling

- Storage Conditions

Provided that RenLam® LY 5210 and Ren® HY 5212 are stored in a dry place in their original, properly closed containers. Partly emptied containers should be closed immediately after use. The product should be used when in the temperature range 18-25°C.

Other

- Application Information

Value Units Test Method / Conditions Mix Ratio 0.4 %(W) %(W) Hardener : Resin