Enhanced TDS

Identification & Functionality

- Chemical Family

- RTU Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Product Features

- Low viscosity components for easy pumping

- Coloured components to indicate mix quality

- Special mix rheology to enable application from 10mm to 20mm thickness

- Rapid cure, but formulated for low exotherm

- Room temperature curing: machinable after 1 day

- Excellent adhesion to clean EPS (expanded polystyrene): pre-treatment not necessary

- Rapid, easy machining formulation, with low noise and dust free shavings

- Fine, seamless surface after machining/ sanding

- Low shrinkage combined with excellent dimensional stability

Applications & Uses

- Compatible Substrates & Surfaces

- Product End Uses

- Markets

- Applications

- Application Information

- Production of seamless plugs and models

- Manufacture of short production-run moulds

Properties

- Physical Form

Technical Details & Test Data

- Curing Cycle

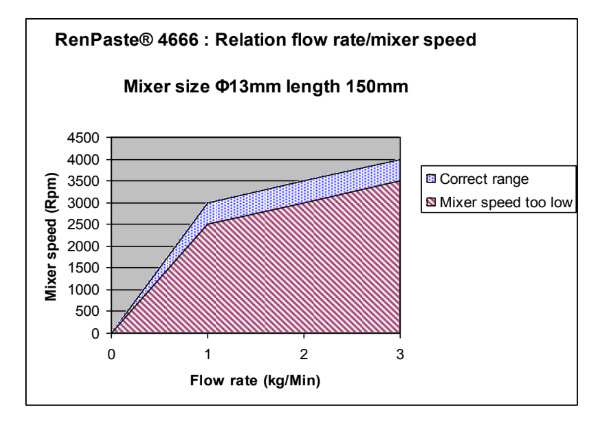

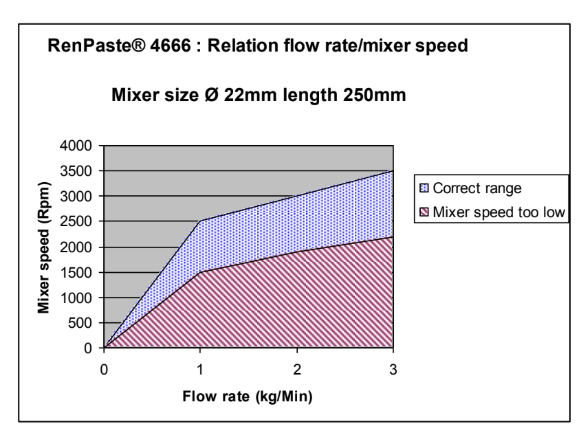

Dynamic Mixer Speed

RenPaste® 4666 is designed to be used with a dynamic type of mixer (rotary mixer element). In addition, the rheology (dynamic viscosity) of the product may be altered by regulation of the mixer speed.

Regulation of the mixer speed allows operators to select from a fluid paste to a thick, highly thixotropic product according to the application requirements.

In order to have a fully mixed paste free from application problems, it is recommended to regulate the mixer within certain limits. The exact speed required will depend on the mixer length, diameter and the flow rate of the paste through the mixer.

Furthermore, a fabric hose with a length of 3 meters to a maximum of 5 meters should be used.- Paste too thin (fluid): Increase mixer speed

- Paste too thick (viscous): Decrease mixer speed

After cure: 7 days at Room Temperature (23°C)

Key Test method Unit Value Density ISO 1183 g/cm³ 0.90 - 1.0 Hardness ISO 868 Shore D 60 - 65 Coefficient of Thermal Expansion ISO 11359 10⁻⁶ k⁻¹ 75 - 80 Glass Transition Temperature TMA °C 56 Compressive Strength ISO 604

MPa

20 Compressive Modulus 1135 Flexural Strength ISO 178

MPa 19 Flexural Modulus MPa 1200 Elongation at Break % 2.2 Linear Shrinkage (Test Sample 500x80x30mm, Released.) mm/m 0.4 Heat Deflection Temperature

Cure Test method Unit Value Cure 7 Days RT (23°C) ISO 75B

°C

52 RT cure + 8 hours 40°C 58 RT cure + 8 hours 60°C 72 RT cure + 8 hours 80°C 82 - Processing Information

Processing

Mix Ratio

Parts by Weight

Parts by Volume

RenPaste® 4666 Resin 100 100 Ren 4666 Hardener 100 100 - It is strongly recommended to apply the paste using a pumping/ dosing machine equipped with screw pumps and a dynamic mixer head. It has been found that static type mixers may not give a homogenous mix quality.

- Apply paste as a single layer up to 20mm in thickness onto a clean, stable substrate (typically 30kg/m3 expanded polystyrene).

- Allow to cure for at least 24 hours at room temperature before machining.

Safety & Health

- Handling Precaution

Our products are generally quite harmless in use provided that normal chemical handling precautions are observed. The uncured materials must not, for instance, be allowed to come into contact with foodstuffs or food utensils, and measures should be taken to prevent direct contact of the uncured materials with the skin, since people with particularly sensitive skin may be

affected. Eye protection and latex or nitrile gloves should be worn when handling the product. The skin should be thoroughly cleansed at the end of each working period using soap and warm water. The use of solvents for skin cleaning is to be avoided. Disposable paper - not cloth towels - should be used to dry the skin. Adequate ventilation of the working area is recommended.

Storage & Handling

- Storage Conditions

Provided that RenPaste® 4666 Resin and RenPaste® 4666 Hardener are stored in a dry place in their original, properly closed containers. Partly emptied containers should be closed immediately after use.

In general Seamless Modeling Pastes should be processed at a minimum temperature of 18°C. Be aware that during winter time it is necessary to store the material at least for one week at 18-20°C before use to assure a complete similar material temperature.

Other

- Application Information

Value Units Test Method / Conditions Mix Ratio 1.0 %(W) %(W) Hardener : Resin