Enhanced TDS

Identification & Functionality

- Chemical Family

- Composite Materials Functions

Features & Benefits

- Labeling Claims

- Materials Features

- PU Benefits

- Line speed up to 2.5 m/min

- Excellent wetting characteristics

- Low pull forces

- Good part surface quality

- Minimal emissions

- Product Features

- Line speed up to 2.5 m/min

- Excellent wetting characteristics

- Low pull forces

- Good part surface quality

- Minimal emissions

Applications & Uses

- Composites End Use

- Composites Processing Methods

- Application Information

- Sporting goods

- Window lineals

- Architectural moldings

- Flat springs

- Lightweight structural supports

- Stabilizer bars

- Transportation panels

- High strength, good deformation resistance.

- Low thermal conductivity, excellent thermal insulation.

- Stable, easy and reliable processing.

- Low VOC, low emissions.

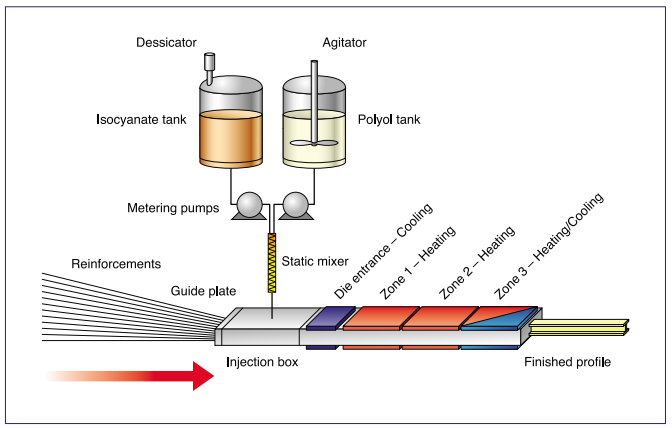

- Processing Requirements

- Temperature controlled die between 100 - 200°C

- Closed Injection box

- Two-component metering pump and static mixer

Technical Details & Test Data

- Processing Information

- Temperature controlled die between 160 - 200°C

- Closed injection box

- Two-component metering pump and static mixer

- Typical Processing Equipment and Conditions

RIMLINE® pultrusion systems are ideally processed on low pressure metering equipment consisting of two material components and a flushing solvent. This low-viscosity system offers multiple advantages in the pultrusion process including excellent wetting of reinforcements, fast reaction kinetics and low pull forces while providing good surface quality at accelerated line speeds with minimal VOCs. Extended gel times of the Huntsman system allow for ease of start-up and system purge.

Schematic of a Typical Polyurethane Pultrusion Set-up

- Polyurethane Resin System for Pultruded Composites

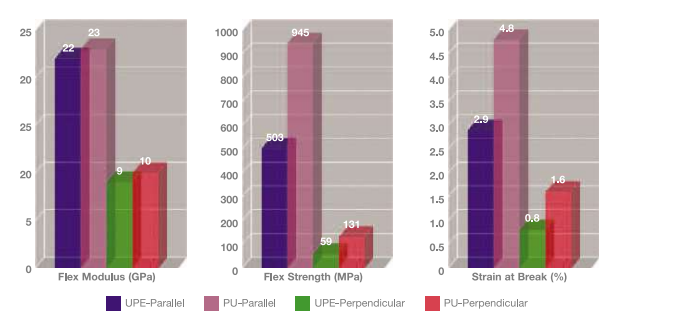

Comparison of Flexural Properties of Unsaturated Polyester (UPE) and Polyurethane (PU) Pultruded Profiles

A flat profile with mat reinforcements on the surface exhibits superior flexural properties when pultruded in a polyurethane resin versus an unsaturated polyester resin.