Enhanced TDS

Identification & Functionality

- Blend

- No

- Chemical Family

- Composite Materials Functions

- Function

- Resins, Binders & Matrix Materials

- Reinforcement Material

- Single Ingredient

- Yes

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Materials Features

- Ready-to-Use Product Features

- Product Benefits

- Moldable - permitting the formation of both thick and thin complex sandwich panels

- Can enable affordable part cost through cost effective resin and production process

- Can provide increased damage resistance by higher toughness and better core adhesion

- Reduced weight with durable mechanical performance

- Can enable high productivity thanks to short cycle times.

- Product Highlights

RIMLINE® WCM polyurethane system creates a face sheet material for overmolding core sandwich composite structures.

Advanced toughness for lightweight battery protection- Versatile and durable, enabling engineering design freedom

- Tunable to help meet customer manufacturing needs

- Can reduce weight and improve impact protection of EV battery packs

- Parts manufacturing with high fiber volume fraction under low pressure

- Developed for: Wet Compression Molding process

- Can enable a cost-effective formulation for affordable sandwich composites

- Can be molded into the complex 3D shape of the ready-to-use core

- Developed to perfectly complement RIMLINE® FC and LFI core resins.

- Benefits

- Moldable – permitting the formation of both thick and thin complex sandwich panels

- Can enable affordable part cost through cost effective resin and production process

- Can provide increased damage resistance by higher toughness and better core adhesion

- Reduced weight with durable mechanical performance

- Can enable high productivity thanks to short cycle times.

Applications & Uses

- Composites End Use

- Composites Processing Methods

- Markets

- Applications

- Application Information

RIMLINE® WCM polyurethane system creates a face sheet material for overmolding core sandwich composite structures that gives underbody battery protection panels their final shape. The system can be tailored to help to achieve a reduction in weight while maintaining stiffness and providing impact protection.

Technical Details & Test Data

- Test Data

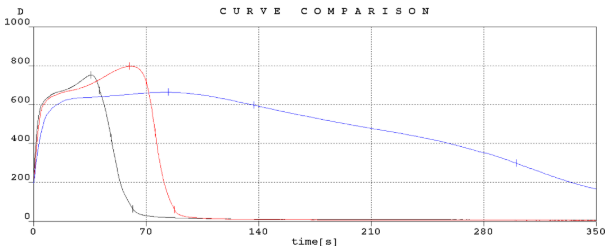

RIMLINE® WCM resin’s reactivity developed for WCM or RTM processes

- Ability to wet out large surfaces.

- Short cure times at processing temperature.

- Pot life* at 120°C is 40 seconds (black line)

- Pot life* at 80°C is 140 seconds (blue line)

- Pot life* at 40°C is >300 seconds

- Pot life* at 90% D

Packaging & Availability

- Regional Availability

Other

- Mechanical Properties

Value Units Test Method / Conditions Compressive Strength -509.0 MPa MPa ISO 14126-1 Compressive Strength 109.0 MPa MPa ISO 604 Flexural Strength 1082.0 MPa MPa ISO 14125 Flexural Strength 127.0 MPa MPa ISO 178 Tensile Strength 82.0 MPa MPa ISO 527 - Physical Properties

Value Units Test Method / Conditions Density 1.2 g/cm³ g/cm³ DIN EN ISO 1183 at 23°C Density 1.2 g/cm³ g/cm³ ISO 1183-3 at 23°C Glass Transition Temperature (Tg) min. 120.0 °C °C Dynamic Mechanical Analysis (DMA)