Enhanced TDS

Identification & Functionality

- Blend

- No

- Chemical Family

- Composite Core

- Function

- Core Material

- Single Ingredient

- Yes

Features & Benefits

- Ready-to-Use Product Features

- Key Features

- Single-shot manufacturing capability

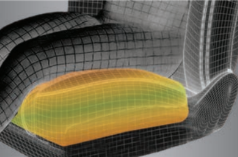

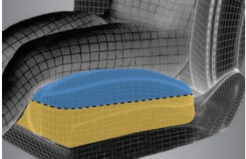

- Soft cushioning top

- Firm bottom layer for overall support

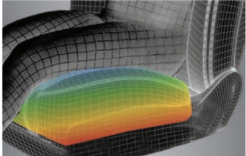

- Tunable gradient effect enables lower layer to be up to 175% firmer than surface

- Fully formulated system

- Standardised manufacturing processes

- Dynamic Advanced Comfort (AC)

- Typical Benefits

- Can provide drivers and passengers with a plush, comfortable ride, and very good initial showroom feel

- Firmness of bottom layers can provide very good overall support, maintaining H-Point

- Better pressure distribution and rolling stability

- Cost savings for automotive manufacturers by reducing steps, time, and labor associated with other manufacturing methods of layered foam

- Minimized craftsmanship issues of separately molded foam layers

Applications & Uses

- Product End Uses

- Markets

- Applications

- Typical Application

RUBIFLEX® Gradient Hardness™ polyurethane system is used in foam seat cushions, typically for densities at or above 65kg/m³.

MARKET LEADING TECHNOLOGY

Conventional seating foam technology is achieved by pouring one polyurethane system targeting a single overall hardness felt at top and bottom of the pad. The result is a seat that trends toward softer with less support, or firmer with less luxurious top-feel.

Some premium seat manufacturing uses two pieces of foam or a ‘topper’ with pad adhered together. The bottom piece of foam is firm while the top piece of foam is soft. The result is added steps and cost in the manufacturing process.

This next generation seating foam technology by Huntsman is completed in one pour, with one formulation. Huntsman’s RUBIFLEX® Gradient Hardness™ polyurethane system can provide optimal comfort for the driver and minimal steps in the manufacturing line, thus saving automakers time and money to deliver a level of comfort previously only experienced with premium seats.

Properties

- Typical System Properties

Range of Gradient Hardness™ Capability demonstrated by core CFDs with 5mm of skin removed per ISO 3386-1 40%.

Index Top CFD (kPa) Bottom CFD (kPa)

70 2.72 5.59 75 3.44 7.36 80 4.52 8.39 85 5.72 10.14 100 8.13 14.35 105 8.56 16.22 CFD = Compression Force Deflection.

Packaging & Availability

- Regional Availability

Other

- Mechanical Properties

Value Units Test Method / Conditions Compression Set 3.44-7.35 % % ISO 33861 0.4, Force Deflection - Physical Properties

Value Units Test Method / Conditions Density 62.0-74.0 kg/m³ kg/m³ ASTM D3574