Enhanced TDS

Identification & Functionality

- Blend

- No

- Chemical Family

- Composite Materials Functions

- Polymer Name

- Reinforcement Material

- Single Ingredient

- Yes

- Technologies

- Product Families

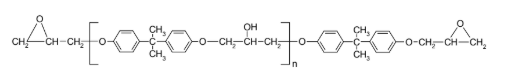

- Chemical Structure

Features & Benefits

- Materials Features

- Advantages

- Complete impregnation of fibers

- High glass transition temperature

- Good mechanical properties

- Low shrinkage

Applications & Uses

- Composites End Use

- Composites Processing Methods

- Markets

- Applications

Regulatory & Compliance

Packaging & Availability

- Regional Availability

Storage & Handling

- Storage Information

Tactix" 123 is supplied in 500 pound steel drums. This product should be stored in a dry place, in the sealed original container, at temperatures between +2°C and +40°C (+35.6°F and +104°F). Under these storage conditions, the shelf life is 5 years. The product should not be exposed to direct sunlight.

Like most liquid epoxy resins, Tactix® 123 may crystallize when stored below room temperature. Heating the resin to 60 - 70°C (140 - 160°F), preferably in a water bath, for several hours, will reliquify it and restore its original properties.

Other

- Appearance (SDS)

- Liquid

- Color (SDS)

- Light Yellow

- Odor (SDS)

- Slight

- Chemical Properties

Value Units Test Method / Conditions Epoxy Equivalent Weight 172.0-176.0 g/eq g/eq - Physical Properties

Value Units Test Method / Conditions Density 1.16 g/cm³ g/cm³ at 25°C Flash Point 251.0 °C °C Closed Cup Viscosity 3200.0-6000.0 mPa.s mPa.s at 27°C