Enhanced TDS

Identification & Functionality

- Blend

- No

- CASE Ingredients Functions

- Chemical Family

- Function

- Binder

- Single Ingredient

- Yes

- Technologies

- Product Families

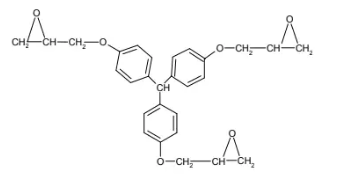

- Chemical Structure

Features & Benefits

- CASE Ingredients Features

- Materials Features

- Advantages

- Trifunctional

- Symmetrical and rigid backbone

- Large distance between epoxy reactive groups

- Provide very high Tg

- Excellent thermal stability

- TACTIX® 742 resin has the highest dry glass transition temperature of any resin in the TACTIX® resin line.

- Most commonly used in adhesive and composite formulation, especially for parts and components near high-heat zones. Aero grade.

Applications & Uses

- Adhesive & Sealant End Applications

- Compatible Substrates & Surfaces

- Markets

- Applications

- Application Details

- Composite and structural adhesives

- Especially for parts and components near high heat zones

Properties

- Physical Form

Regulatory & Compliance

Packaging & Availability

- Regional Availability

Storage & Handling

- Storage Information

TACTIX® 742 should be stored between 2 and 40°C in original container protected from direct sunlight in a dry, cool and well-ventilated area, away from food, drink and incompatible materials. Keep container tightly closed and sealed until ready for use. Containers that have been opened must be carefully resealed and kept upright to prevent leakage. Don’t store in unlabelled containers. Use appropriate containment to avoid environmental contamination.

Other

- Appearance

- Yellow to brown solid resin

- Color (SDS)

- Dark amber

- Insoluble in (SDS)

- Water

- Odor (SDS)

- Slight

- Physical Properties

Value Units Test Method / Conditions Density 1.23 g/cm³ g/cm³ At 25°C Flash Point min. 200.0 °C °C Closed Cup Flash Point min. 200.0 °C °C DIN 51758 Viscosity 700.0-800.0 - at 100°C Viscosity 25.0-60.0 - ISO 3219 1500°C, Brookfield CAP 2000