Enhanced TDS

Identification & Functionality

- Chemical Family

Features & Benefits

- Materials Features

Applications & Uses

- Plastics & Elastomers Processing Methods

- Markets

- Applications

- Application Information

With its elastic properties, Tecnothane® MPT450MX is particularly fitting for car shock absorbers.

Properties

- Physical Form

Regulatory & Compliance

Technical Details & Test Data

- Casting Information

Density (g/cm³) MPT450MX RH300MX Catalyst (%) Molds T (°C) Cream time (sec) Demolding (min) * 100.00 10.33 ** 50 5-7 10-12 The amount of main components is given on parts by weight.

*When casting car shock absorbers, it is necessary to keep a 10% higher density than the one required with an NDI-based system.

**Pot life and demolding time are referred to the system without catalyst, Tecnokat D5 can be used to adjust pot life and demolding time.- Test Data

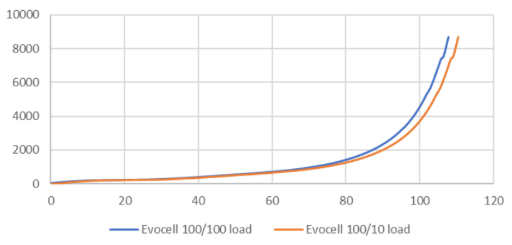

Compression test load (N) Vs deformation (mm)

Fatigue test: 500,000 cycles at 1,5Hz frequency with deformation between 0 and 69%

Deformation at cycle end: 5% (ref. NDI-foam 3%)- Post Curing Information

Do not allow excessive cooling of molded parts between demolding and post-curing.

Cycle Temperature (°C) Time (hours) 1 70 16 It is recommended to wait 24 h at room temperature before the post-curing cycle.

Packaging & Availability

- Regional Availability

- Storage Information

Materials are available in following packaging: 50 or 200 kg

Storage & Handling

- Handling Information

- In order to allow complete melting, pre-heat materials at following conditions (melting times are referred to 200 kg drums,stored at 20°C)

Pre-heating temperature (°C) 70 Pre-heating time (hours) 24 - After pre-heating, make sure all materials are completely melted.

- Add water to RH300MX in the quantity specified on the label of the material.

- Well mix melted material by drilling or rolling the drum

- Load materials to the machine immediately after mixing.

- Materials must be stored under nitrogen blanket after use.

Other

- Appearance (SDS)

- Solid

- Color (SDS)

- White

- Odor (SDS)

- Characteristic

- Mechanical Properties

Value Units Test Method / Conditions Compression Set 5.0 % % ISO 1856 Elongation 500.0 % % ISO 1798 Hardness 60.0 Shore A Shore A ISO 7619 Tear Strength 5.5 kN/m kN/m ISO 8067 Tensile Strength 7.0 N/mm² N/mm² ISO 1798 - Physical Properties

Value Units Test Method / Conditions Density 0.53 g/cm³ g/cm³ Viscosity1 4000.0 mPa.s mPa.s