Enhanced TDS

Identification & Functionality

- Blend

- No

- Chemical Family

- Composite Materials Functions

- Single Ingredient

- Yes

- Technologies

- Product Families

Features & Benefits

- Materials Features

- Key Properties

- Homogeneous insulation.

- Good mechanical and electrical properties.

- Excellent adhesion to the substrate.

- Good resistance to humidity.

- Practically no emission.

- Proven excellent long term storage and tank stability.

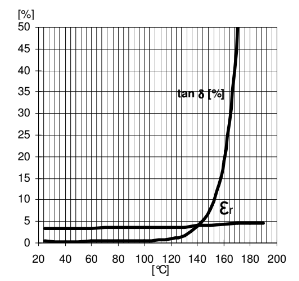

- Low loss tangent at high temperature.

Applications & Uses

- Application Area

- Composites End Use

- Composites Processing Methods

- Product End Uses

- Markets

- Applications

- Processing Information

- Vacuum pressure impregnation.

- Dip rolling impregnation process.

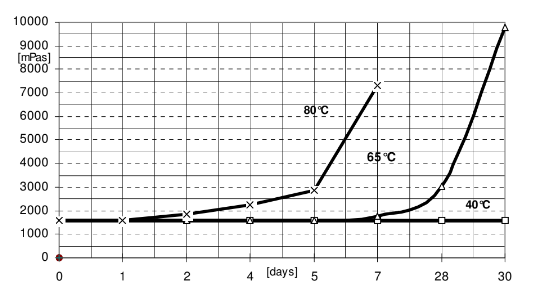

- Long potlife up to 40°C.

Properties

- Physical Form

Regulatory & Compliance

- Certifications & Compliance

- Chemical Inventories

Technical Details & Test Data

- Test Data

Fig.1: Loss factor (tan δ) and dielectric constant (εr) as a function of temperature

(measurement frequency: 50 Hz / DIN 60250/

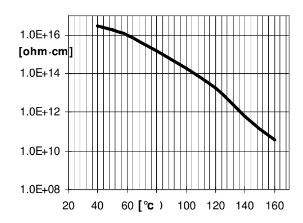

Fig.2: Volume resistivity (ρ) as a function of temperature

(measurement voltage: 1000 V / IEC 60093)- Processing Viscosities

Fig.1: Viscosity measured at 25°C, after storage at 40°C, 65 and 80°C

Measurements with Rheomat 115, Shear rate D = 10 s-1

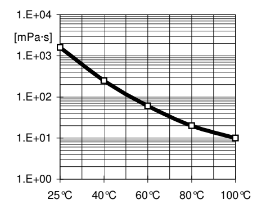

Fig 2: Initial viscosity as a function of temperature

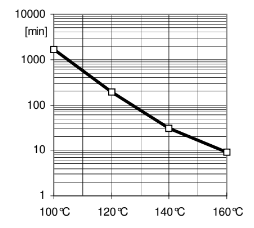

Measurements with Rheomat 115, D =10 s-1- Gelation / Cure time

Fig.1: Geltime measured with Gelnorm Instrument as a function of temperature (ISO 9396)

Storage & Handling

- Storage

Store the components in a dry place according to the storage conditions stated on the label in tightly sealed original containers. Under these conditions, the shelf life will correspond to the expiry date stated on the label. After this date, the product may be processed only after reanalysis. Partly emptied containers should be tightly closed immediately after use.

Other

- Appearance

- Clear to slightly hazy, pale-yellow liquid free from solid matter

- Color (SDS)

- Light

- Insoluble in (SDS)

- Water

- Odor (SDS)

- Slight

- Mechanical Properties

Value Units Test Method / Conditions Flexural Strength 95.0-105.0 MPa MPa ISO 178 at 23°C Hardness 80.0-85.0 Shore D Shore D at 25°C Hardness 80.0-85.0 Shore D Shore D DIN 53505 at 25°C Tensile Strength 40.0-50.0 MPa MPa ISO 527 at 23°C - Physical Properties

Value Units Test Method / Conditions Density 1.16-1.17 g/cm³ g/cm³ ISO 2811-3 at 25°C Glass Transition Temperature (Tg) 120.0-140.0 °C °C Differential Scanning Calorimetry Glass Transition Temperature (Tg) 120.0-140.0 °C °C ISO 11357-2 Viscosity 1350.0-1850.0 mPa.s mPa.s ISO 2884 at 25°C - Thermal Properties

Value Units Test Method / Conditions Thermal Conductivity1 0.2-0.3 W/m·K W/m·K