Enhanced TDS

Identification & Functionality

- CASE Ingredients Functions

- Chemical Family

- Function

- Accelerator, Catalyst, Hardener, Curing Agent

- Technologies

- Product Families

Features & Benefits

- CASE Ingredients Features

- Key Properties

- Co-hardener when used with polyamine, polyamidoamines and their adducts

- Good compatibility with amine hardeners

- Effective accelerator and co-hardener in polyurethane systems

- Good for low temperature and waterborne systems

- Accelerator with no leaching effect.

- Good property retention due to its amine functionality.

- Enables solvent free coatings – low VOC formulations.

- Reactive

- Tertiary amine based accelerator

- For ambient cure epoxy systems

- Low plasticising effect

- Product Features

- Reactive

- Tertiary amine based accelerator

- For ambient cure epoxy systems

- Low plasticising effect

- Key Benefits

- Accelerator with no leaching effect.

- Good property retention due to its amine functionality.

- Enables solvent free coatings – low VOC formulations.

Applications & Uses

- Coating End Applications

- Compatible Polymers & Resins

- Markets

- Applications

- Application Information

In solvent free coatings:

- At low use levels, Accelerator 2950 produces the same effect as the industry standard tertiary amine such as Accelerator 960-1

- At high use levels, e.g., 20phr, Accelerator 2950 increases cure speed dramatically and coatings are open to foo traffic after 24 hours at 5°C.

In solvent containing coatings:

- At low use levels, Accelerator 2950 produces the same effect as Accelerator 960-1 but nearly twice the pot life.

- At high use levels, Accelerator 2950 give the same effect as in solvent free coatings.

In polyurethane systems:

- More dramatic results than in epoxy systems.

- Extremely short de-molding times for tooling systems.

Properties

- Physical Form

Regulatory & Compliance

Technical Details & Test Data

- Test Data

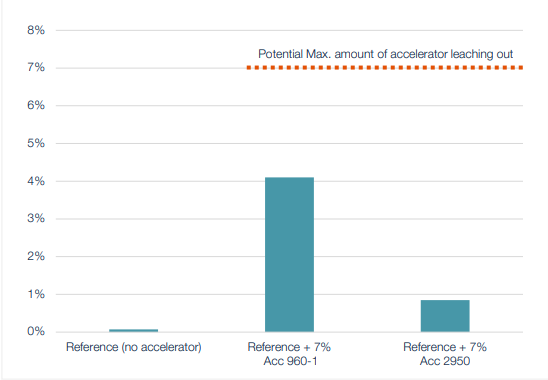

No Leaching Effect:

Its unique amine functionality gives it the ability to co-react with the epoxy resin, making it part of the polymer backbone. The normal leaching is 5 times less than other accelerators, minimizing the impact on chemical or corrosion resistance properties.

Reference system: ARALDITE® GY 250 fully cured with IPDA based hardener ARADUR® 20315

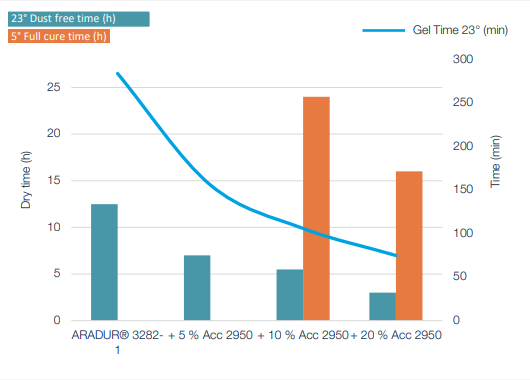

Drying and Gel Time:

Accelerator 2950 offers a good balance between faster drying time and reduction of gel time also at low temperatures.

Standard low viscosity Epoxy

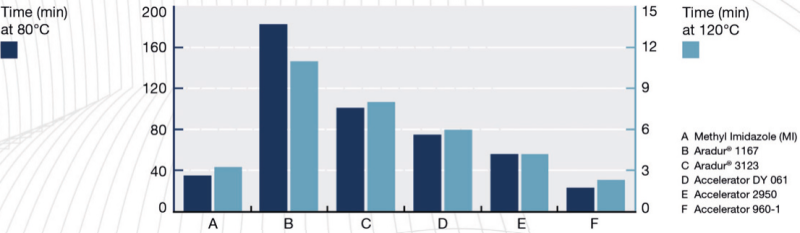

- Accelerators for Anhydride Hardeners

Product Latency / reactivity Impact on mechanical properties Form/processability Reference Methyl Imidazole (MI) Very fast High Tg Standard modulus Liquid (~ 40mpa.S) Accelerator 2950 Almost equivalent to reference Higher modulus medium Tg Liquid (~ 4000 mpa.S) Kinetics

Viscosity build-up, time to reach 1 000 Pa.s

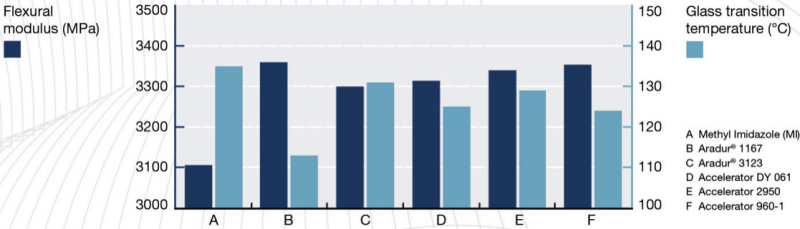

Thermo-mechanical properties

Modulus and Tg

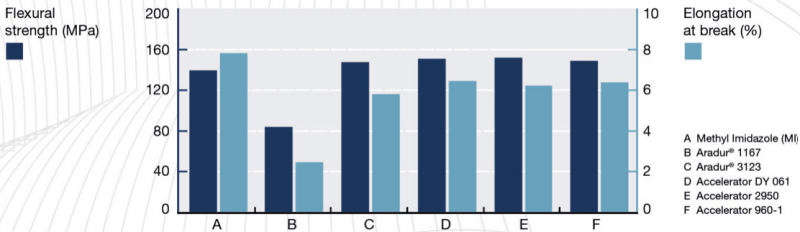

Mechanical properties

Elongation at break and flexural strength

Note: Detailed information about Accelerators for dicyandiamide hardeners & Accelerators for amine cure from RT to 60°C can be accessed through this link.

- Effect

ARALDITE®GY 250 100 100 100 ARALDITE®GZ 7071 X 75 100 10 100 ARADUR®2963-1 45 45 22 ARADUR® 115 38 38 38 ACCELERATOR 2950 CH 1.5 20 0.7 6 Xylene / Butanol ( 4 : 1 ) 72 70 67 Pot life (min) 40 22 12 390 180 30 Dust dry time 20°C 65% r.h. (h) 4 3 1 7 5 1 Persoz hardness 1 day 5°C (s) 22 30 240 30 24 100

Packaging & Availability

- Regional Availability

Storage & Handling

- Storage Information

- Accelerator 2950 should be stored at room temperature in the original sealed container. The expiry date is indicated on the label.

- Handling Precautions

Caution

To protect against any potential health risks presented by our products, the use of proper personal protective equipment (PPE) is recommended. Eye and skin protection is normally advised. Respiratory protection may be needed if mechanical ventilation is not available or is insufficient to remove vapors.

Other

- Appearance

- Pale yellow liquid

- Color (SDS)

- Yellow

- Odor (SDS)

- Amine like

- Application Information

Value Units Test Method / Conditions Mix Ratio 39.0 g/100g g/100g - Chemical Properties

Value Units Test Method / Conditions Amine Hydrogen Equivalent Weight 75.0 g/eq g/eq Amine Value 640.0-700.0 mg KOH/g mg KOH/g - Physical Properties

Value Units Test Method / Conditions Density 0.99 g/cm³ g/cm³ At 20°C Flash Point min. 110.0 °C °C Closed Cup Viscosity 2000.0-6000.0 cPs cPs At 25°C