Enhanced TDS

Identification & Functionality

- Chemical Family

- RTU Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Product Features

- Flexible processing and cure cycle

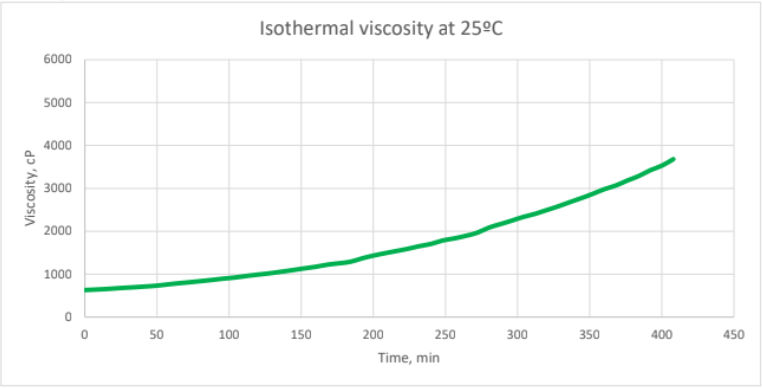

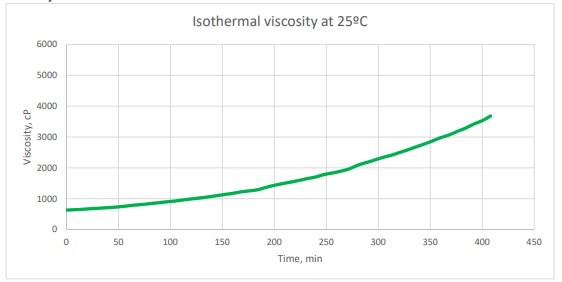

- Low viscosity and long injection window at ambient temperatures

- Rapid cure due to moderate enthalpy

- Low temperature cure (121ºC) with 130ºC glass transition temperature

- High fracture toughness K¹C 1.8 MPa√m

- Features and Benefits

- Flexible processing and cure cycle

- Low viscosity and long injection window at ambient temperatures

- Rapid cure due to moderate enthalpy

- Low temperature cure (121°C) with 130°C glass transition temperature

- High fracture toughness K1C 1.8 MPa√m

Applications & Uses

- Composites Processing Methods

- Product End Uses

- Markets

- Applications

- Application Information

ARA DEFEND® 50100 RESIN SYSTEM is a two-component liquid infusion system designed for the manufacture of components requiring high-damage tolerance or multiple impact events, such as composite ballistic armor systems.

- Application Information

ARA DEFEND® 50100 A/B is a two-component liquid infusion system designed for the manufacture of components requiring high-damage tolerance or multiple impact events, such as composite ballistic armor systems.

Properties

- Physical Form

Technical Details & Test Data

- Uncured Resin Properties

- ARA DEFEND® 50100 Part A and ARA DEFEND® 50100 Part B are added to approriate kettle

- Mixing under full vacuum at room temperature until homogeous and free of air

- Mold temperature at room temperature

- Injection / infusion lines at room temperature

- Mold / bagging leakage: below 15 mbar in 5 min

- Vacuum Infusion: below 5 mbar

- Cure Cycle: 180 min at 121°C, no post cure required (degree of cure >90%)

- Processing Information

Uncured Resin Properties

Processing Information

- ARA DEFEND® 50100 A/B are added to approriate kettle

- Mixing under full vacuum at room temperature until homogeous and free of air

- Mold temperature at room temperature

- Injection / infusion lines at room temperature

- Mold / bagging leakage: below 15 mbar in 5 min

- Vacuum Infusion: below 5 mbar

- Cure Cycle: 180 min at 121ºC, no post cure required (degree of cure min. 90%)

Neat Resin Properties

Property Value Unit Test Method Condition DSC Onset Temperature 81 ºC ASTM 3418 DSC Enthalpy 385 J/g DSC Peak 197 ºC Cure Schedule 3hr at121ºC Density 1.15 g/cm³ DMA, Tg 130 ºC D-4065 Degree of Cure 90 % Tensile Strength 8.05 ksi D-638 Tensile Modulus 355 ksi Tensile Elongation 8.63 % Flexural Strength 14.7 ksi D-790 Flexural Modulus 351 ksi Flexural Strain 7.1 % Fracture Toughness, K1C 1.8 MPa√m D-5045 Fracture Toughness, G1C 1629 J/m² Laminated Properties

Property Value Unit Test Method Condition Fiber type 463 S-2 Plain weave glass

24 oz/yd² Fiber volume, Fv 50 % Tensile strength 80 ksi D-3039 Tensile modulus 4.3 msi Compression strength 46 ksi D-6641 Compression modulus 4.2 msi ILSS 5.8 ksi D-2344 Flexural strength 62 ksi D-7264

Packaging & Availability

- Regional Availability

Storage & Handling

- Storage Information

- ARA DEFEND® 50100 Part A and ARA DEFEND® 50100 Part B should be stored in a dry place at 23°C - 25°C.

- Under these storage conditions the shelf life is 24 months. The product should not be exposed to direct sunlight.

- Storage Conditions

ARA DEFEND® 50100 A/B should be stored in a dry place at 23°C - 25°C. Under these storage conditions the shelf life is 24 months. The product should not be exposed to direct sunlight.

Other

- Application Information

Value Units Test Method / Conditions Mix Ratio 0.339 %(W) %(W) Hardener : Resin