Enhanced TDS

Identification & Functionality

- CASE Ingredients Functions

- Chemical Family

- Function

- Hardener

- Technologies

- Product Families

Features & Benefits

- CASE Ingredients Features

- Labeling Claims

- Key Features

ARADUR® 36 contains no organic solvents. It represents an optimum solution in terms of solids content at medium viscosity. When Aradur 36 is diluted with water, turbidity may occur below a 65% solids content level. In pre-pigmented form, however, more stable hardener solutions can be produced. In combination with liquid epoxy resins, relatively slow-drying films with good flow properties, good adhesion, flexibility and a high gloss finish can be achieved. With (proportional) use of solid resin dispersions such as Araldite PZ 3961-1, drying times can be significantly shortened. ARADUR® 36 provides good anti-corrosion properties. The pot life of dispersion coatings formulated with Aradur 36 is typically limited to a maximum of 2.5 hours (loss of gloss finish). A clear increase in viscosity occurs later especially in heavily diluted mixtures.Aradur® 36 Epoxy Curing Agent Universal water-based curing agent. Used for floor topcoat When it has high adhesion, high gloss, good Anti-UV yellowing performance. With extremely high solid content and Relatively low viscosity, suitable for high solid content coatings Materials such as self-leveling thick coating, epoxy cement, etc.

- Features

Aradur® 36 Epoxy Curing Agent Universal water-based curing agent. Used for floor topcoat When it has high adhesion, high gloss, good Anti-UV yellowing performance. With extremely high solid content and Relatively low viscosity, suitable for high solid content coatings Materials such as self-leveling thick coating, epoxy cement, etc.

Applications & Uses

- Coating End Applications

- Compatible Substrates & Surfaces

- Application Information

Used with liquid epoxy resins such as Araldite® GY9708-3, GY 776 or the emulsion PZ 33757/67, ARADUR® 36 is suitable for the formulation of water-based coatings for application to mineral and metallic substrates. Particularly suitable for solvent-free dispersion coatings with a high solids content and for epoxy cement concrete.

Properties

- Physical Form

- Mix Ratio

- The recommended mix ratio of Araldite GY 776 and ARADUR® 36 is 100:88 parts by weight.

- The recommended mix ratio of Araldite PZ 33757/67 and ARADUR® 36 is 100:62 parts by weight.

- The recommended mix ratio of Araldite PZ 3961-1 and ARADUR® 36 is 100:17 parts by weight.

- Deviations from this of up to 10 % can be tolerated. In this connection, a higher proportion of hardener results in greater flexibility and better adhesion, while improved levels of anti-corrosion protection are achieved with a lower proportion of hardener.

Regulatory & Compliance

- Chemical Inventories

Technical Details & Test Data

- Operation Guideline

1.ARADUR® 36 diluting

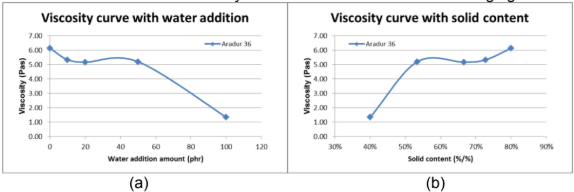

ARADUR® 36‘s solid content of is as high as 80% and its viscosity is about 6Pas. Customer can dilute ARADUR® 36 according to certain requirement. The viscosity vs. water addition amount and viscosity vs. solid content curve like following figures:

Fig.1 ARADUR® 36 viscosity diluting curve: (a) viscosity vs. Water addition amount; (b) viscosity vs. solid content

When the water addition amount is more than 50phr, ARADUR® 36 can be diluted effectively. If necessary, customer can use polar solvent to diluent ARADUR® 36, such as alcohol.

2.Pigment & filler dispersing

2.1 Select pigment & filler

ARADUR® 36 is water-based polyamine and behave weak alkaline. ARADUR® 36 should be formulated with neutral or alkaline pigment and filler. And pigment/filler should be compatible with amine system. In most cases, titanium dioxide like inorganic pigment is compatible with ARADUR® 36 well. When using organic pigment, please confirm if it is compatible with water based system.

In most cases, TALC, barium sulfate, wollastonite, nepheline and calcium carbonate should be compatible with ARADUR® 36. However, the compatibility is highly dependent on the surface treatment of filler. Pigment and filler’s content, particle size will determine ARADUR® 36’s formulation rheology, appearance and process properties. Generally speaking, higher viscosity is attribute to filler’s higher content, lower size, higher oil absorption or better dispersing. Customer should adjust the pigment/filler type and content according to real process requirement.

2.2 Select dispersing agent

When dispersing pigment and filler in ARADUR® 36 solution, suitable dispersing agent and right adding sequence is necessary. Water based silicone dispersing agent can disperse pigment and filler effectively, such as Disperbyk® 192. The amount of dispersing agent is depended on the filler volume.

2.3 Select dispersing process

Normally, high speed disperser and dispersing pan can disperse many kind of pigment and filler effectively. The dispersing speed is dependent on the disperser capability and real field condition. If necessary, ball mil or triple roll mil should be used to disperse pigment & filler.3.Additives selection and adding sequence

Water based silicone defoamer can eliminate foam in ARADUR® 36 formulated system effectively while keep good compatibility, such as BYK 019, BYK 024 and etc. Water based silicone surfactant can wet substrate effectively, such as BYK 345, BYK 346 and etc. The addition amount of defoamer and surfactant is dependent on the total formulation amount. When formulating ARADUR® 36 system, following sequence can be followed : 1 st step : add defoamer, dispersing agent and water, mix evenly with high speed ; 2 nd step : add pigment, filler and increase mixing speed. Grid the mixture til the fineness is acceptable ; 3rd step : decrease mixing speed. Add surfactant, flash rush inhibitor, thickener or other additives. Then add water to decrease viscosity.4.Formulation tips

4.1 Adjust reacting/drying speed

To shorten tack-free period, alcohol or other fast drying polar solvent can be used. To shorten both tack-free period and cure-through period, Accelerator 960-1 can be added into formulation. It also can be achieved by adding other faster drying curing agents, such as Aradur 39 and Aradur 3985. To extend pot life, more solvent can be added, such as water, alcohol or propylene glycol monomethyl ether. It also can be achieved by adding acetic acid. However, all of above methods will change other performance.

4.2 Adjust film hardness

To increase film hardness, multi-functional epoxy can be added into formulation, such as Araldite EPN1183, Araldite EPN1179; To decrease the hardness and improve flexibility, reactive diluent can be added into formulation, such as Araldite DY-E, Araldite DY-3601, Araldite DY-D.

4.3 Improve chemical resistance

Following approaches can be used to improve chemical resistance:

Method 1, increase epoxy stoichiometric ratio in formulation. 10% to 20% excess of epoxy part will improve the acid resistance while not decreasing other properties greatly;

Method 2, select right reactive diluent. Araldite DY-K diluent have good acid resistance ;

Method 3 : select multi-functional epoxy, such as Araldite EPN1183、Araldite EPN1179 or Araldite PZ 323.5.Application enviroment

Temperature below 10°C or humidity above 70% should be avoided. Good ventilationshould be provided during application.

Packaging & Availability

- Regional Availability

Storage & Handling

- Storage Information

ARADUR® 36 should be stored in a dry place, preferably in the sealed original container, at temperatures between 2 and 40°C (temperatures will never be allowed to drop under 0°C). The product should not be stored exposed to direct sunlight.

Other

- Appearance

- Clear liquid

- Color (SDS)

- Light Yellow

- Odor

- Amine

- Application Information

Value Units Test Method / Conditions Mix Ratio 88.0 g/100g g/100g With Araldite® GY 6010 Liquid Epoxy Resin - Chemical Properties

Value Units Test Method / Conditions Amine Value 185.0-225.0 mg KOH/g mg KOH/g ISO 9702 - Physical Properties

Value Units Test Method / Conditions Density 1.04 g/cm³ g/cm³ ISO 1675 at 20°C Flash Point min. 190.0 °C °C Pensky-Martens Closed Cup (PMCC) Flash Point min. 190.0 °C °C ISO 2719 Viscosity 4000.0-7000.0 mPa.s mPa.s ISO 3219 at 25°C Viscosity 4000.0-7000.0 mPa.s mPa.s Rotational Viscometer at 25°C