Enhanced TDS

Identification & Functionality

- Chemical Family

- RTU Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Product Properties

- Excellent heat resistance up to 210 °C after post-cure

- Self levelling

- Good environmental resistance

- Long pot life

Applications & Uses

- Applications

- The resin/hardener mix may be applied manually or robotically to the pretreated and dry joint surfaces.

- Huntsman stresses that proper adhesive joint design is critical for a durable bond.

- The joint components should be assembled and secured in a fixed position as soon as the adhesive has been applied.

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Cured Properties

Typical Cured Properties

- Unless otherwise stated, the figures given below were all determined by testing standard specimens made by lap-jointing 114 x 25 x 1.6 mm strips of aluminium alloy. The joint area was 12.5 x 25 mm in each case.

- The figures were determined with typical production batches using standard testing methods. They are provided solely as technical information and do not constitute a product specification.

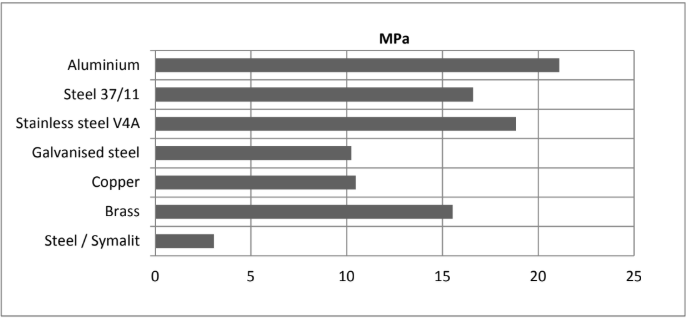

Average lap shear strengths of typical metal-to-metal joints (ISO 4587) (typical average values)

- Cured 2h/120°C

- Pretreatment - Sand blasting + degreasing

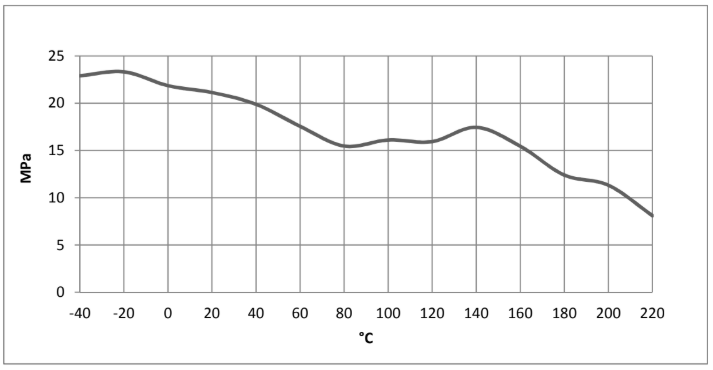

Lap shear strength versus temperature (ISO 4587) (typical average values)

- Cured for 2h/120 °C

- Pretreatment - Sand blasting + degreasing

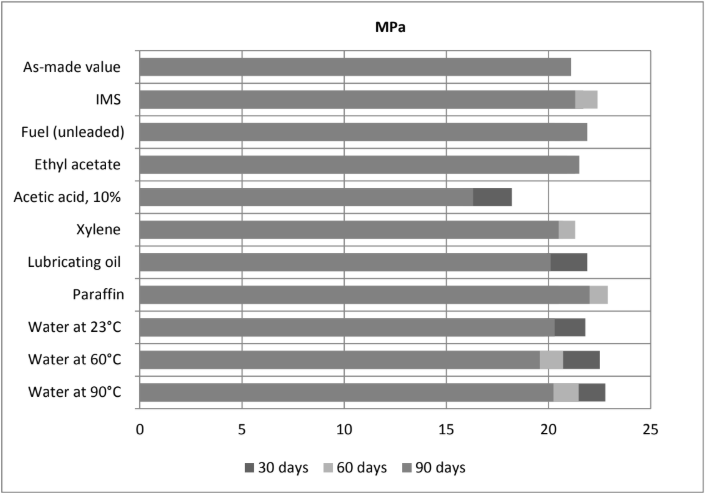

Lap shear strength versus immersion in various media (ISO 4587) (typical average values)

- Unless otherwise stated, L.S.S. was determined after immersion for 90 days at 23°C

- Cure 2 hours at 120°C

- Pretreatment - Sand blasting + degreasing

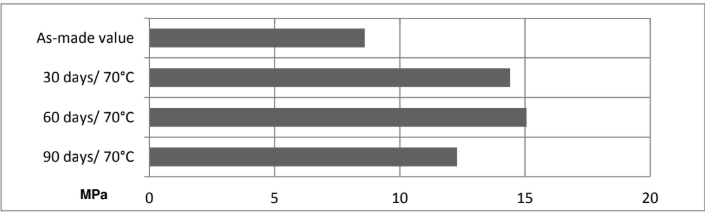

Lap shear strength versus heat ageing (ISO 4587) (typical average values)

- Cure: 16 hours at 40°C

- Pretreatment - Sand blasting + degreasing

Typical Mechanical Properties

Property Value Unit Test Method at Condition Tensile Strength 53 MPa ISO 527 Cure: 24 hours at RT + 2 hours at 90°C, tested at 23°C

Tensile Modulus 6200 MPa ISO 527 Cure: 24 hours at RT + 2 hours at 90°C, tested at 23°C

Elongation at Break 1.4 % ISO 527 Cure: 24 hours at RT + 2 hours at 90°C, tested at 23°C

Shore D Hardness 90 Shore D ISO 868 Cure: heated up gradually up to 180°C

Coefficient of Thermal Expansion 50 × 10⁻⁶ K⁻¹ ISO 11359 Cure: heated up gradually up to 180°C

Glass Transition Temperature (Tg) by DSC

Cure Cycle Tg (onset) Tg (midpoint) Unit 1h at 80°C 55°C 60°C °C 1h at 120°C 110°C 130°C °C 2h at 120°C 120°C 140°C °C 1h at 150°C 150°C 160°C °C 1h at 120°C + 1h at 180°C 155°C 170°C °C - Processing Information

Pretreatment

- The strength and durability of a bonded joint are dependent on proper treatment of the surfaces to be bonded.

- At the very least, joint surfaces should be cleaned with a good degreasing agent such as acetone or other proprie- tary degreasing agents in order to remove all traces of oil, grease and dirt. Low-grade alcohol, gasoline (petrol) or paint thinners should never be used.

- The strongest and most durable joints are obtained by either mechanically abrading or chemically etching (“pick- ling”) the degreased surfaces.

- Abrading should be followed by a second degreasing treatment.

Mix Ratio Parts by Weight Parts by Volume

Araldite® AW 4804 100 100 Hardener HW 4804 15 28 Equipment maintenance

- All tools should be cleaned with hot water and soap before adhesives residues have had time to cure.

- The removal of cured residues is a difficult and time-consuming operation.

- If solvents such as acetone are used for cleaning, operatives should take the appropriate precautions and, in addition, avoid skin and eye contact.

Typical cure requirements

- To achieve optimum performance properties an elevated temperature cure is recommended. This adhesive will not reach sufficient cure at temperatures below 100°C.

- Suggested cure schedules are:

- 2h at 120°C

- 1h at 150°C

- 1h at 120°C + 1h at 180°C

Storage & Handling

- Storage and Handling Precautions

Storage

-

Araldite® AW 4804 and Hardener HW 4804 must be stored at 2-18°C in the original sealed containers.

Handling Precautions

- Our products are generally quite harmless to handle provided that certain precautions normally taken when handling chemicals are observed.

- The uncured materials must not, for instance, be allowed to come into contact with food- stuffs or food utensils, and measures should be taken to prevent the uncured materials from coming in contact with the skin, since people with particularly sensitive skin may be affected.

- The wearing of impervious rubber or plastic gloves will normally be necessary; likewise the use of eye protection.

- The skin should be thoroughly cleansed at the end of each working period by washing with soap and warm water.

- The use of solvents is to be avoided. Disposa- ble paper - not cloth towels - should be used to dry the skin.

- Adequate ventilation of the working area is recommended.

-

Other

- Appearance

- Grey paste

- Application Information

Value Units Test Method / Conditions Mix Ratio 0.15 - Hardener : Resin - Physical Properties

Value Units Test Method / Conditions Specific Gravity approx. 1.65 - Viscosity approx. 17.0 Pa.s Pa.s