Enhanced TDS

Identification & Functionality

- Chemical Family

- RTU Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Key Features

- Good thermal conductivity.

- Low water absorption.

- Excellent thermal endurance.

- Flammability UL 94 V-0 (6.0 mm).

- UL 1446 System Temp Class 180(H).

- Railway EN 45545-2, R22 HL2 / R23 HL3

- Suitable for Explosion-proof castings

- Features and Benefits

- Good thermal conductivity

- Low water absorption

- Excellent thermal endurance

- Flammability of UL 94 V0 for 6.0 mm thick plaque

- UL 1446 System Temperature Class 180 (H)

- Railway certified EN 45545-2 R22 HL2 / R23 HL3

Applications & Uses

- Application Area

- Composites Processing Methods

- Product End Uses

- Markets

- Applications

- Application Details

- Transformers, filters, capacitors, etc.

- Electrical devices working in potentially

- Explosive environment

Properties

Regulatory & Compliance

- Certifications & Compliance

- Quality Standards

Technical Details & Test Data

- Cured Properties

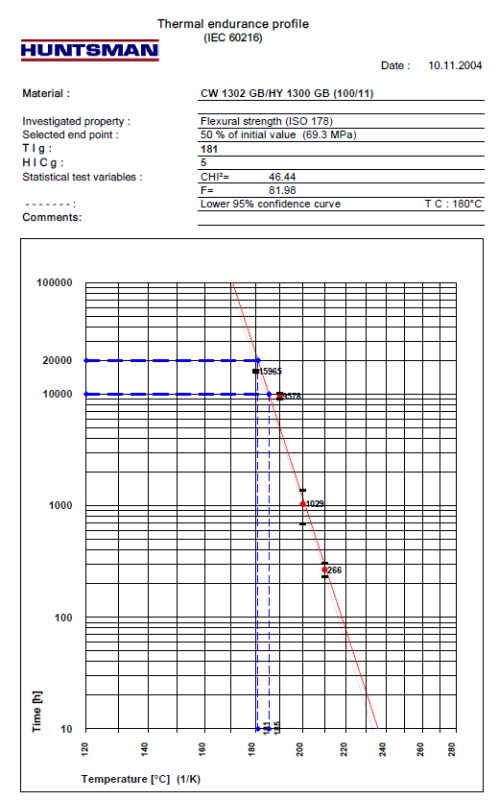

Key Value Unit Test Method Test Condition Glass transition temperature by DSC 74 - 76 °C ISO 6721 at 23°C, cured 24 hours at 25 °C plus 6 hours at 60°C Modulus in torsion G’ at 25°C 3,350 - 3,400 MPa ISO 6721 at 23°C, cured 24 hours at 25 °C plus 6 hours at 60°C Temperature index 181 °C IEC 60216 at 23°C, cured 24 hours at 25 °C plus 6 hours at 60°C System Temperature Class 180 (H) UL 1446 at 23°C, cured 24 hours at 25 °C plus 6 hours at 60°C Tensile strength 34 - 36 MPa ISO 527 at 23°C, cured 24 hours at 25 °C plus 6 hours at 60°C Tensile elongation at break 0.7 - 0.8 % ISO 527 at 23°C, cured 24 hours at 25 °C plus 6 hours at 60°C Tensile modulus 7,690 - 7,710 MPa ISO 527 at 23°C, cured 24 hours at 25 °C plus 6 hours at 60°C Flexural strength 64 - 66 MPa ISO 178 at 23°C, cured 24 hours at 25 °C plus 6 hours at 60°C Flexural modulus 8,450 - 8,550 MPa ISO 178 at 23°C, cured 24 hours at 25 °C plus 6 hours at 60°C Thermal linear coefficient (Alpha 1) 41 - 43 ppm/K ISO 11359-2 before Tg (at 23°C), cured 24 hours at 25 °C plus 6 hours at 60°C

Thermal linear coefficient (Alpha 2) 104 - 106 ppm/K ISO 11359-2 after Tg (at 23°C), cured 24 hours at 25 °C plus 6 hours at 60°C

Thermal conductivity 0.87 - 0.89 W/m·K ISO 8894-1 at 23°C, cured 24 hours at 25 °C plus 6 hours at 60°C Hardness 88 Shore D DIN 53505 at 23°C, cured 24 hours at 25 °C plus 6 hours at 60°C Flammability (UL file E96722) V0 - UL 94 6 mm thickness, cured 24 hours at 25 °C plus 6 hours at 60°C Flammability HB - UL 94 1.5 mm thickness, cured 24 hours at 25 °C plus 6 hours at 60°C

Oxygen Index 36.1 % ISO 4589-2 at 23°C, cured 24 hours at 25 °C plus 6 hours at 60°C Smoke Density 238 - ISO 5659-2 at 23°C, cured 24 hours at 25 °C plus 6 hours at 60°C Smoke Toxicity 0.81 - NF X 70-100 at 23°C, cured 24 hours at 25 °C plus 6 hours at 60°C Water absorption 0.03 - 0.05 % by wt. ISO 62 1 day at 23°C, cured 24 hours at 25 °C plus 6 hours at 60°C Water absorption 0.21 - 0.23 % by wt. ISO 62 30 minutes at 100°C, cured 24 hours at 25 °C plus 6 hours at 60°C

Dielectric strength 26 - 28 kV/mm IEC 60243-1 at 23°C, 2mm thick plate, cured 24 hours at 25 °C plus 6 hours at 60°C

Dielectric strength (4.0 kV at 140°C) >300 kV EN 50028 at 140°C, 2mm thick plate, cured 24 hours at 25 °C plus 6 hours at 60°C

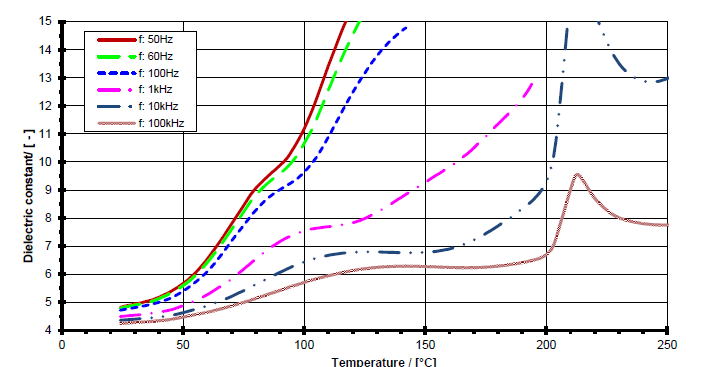

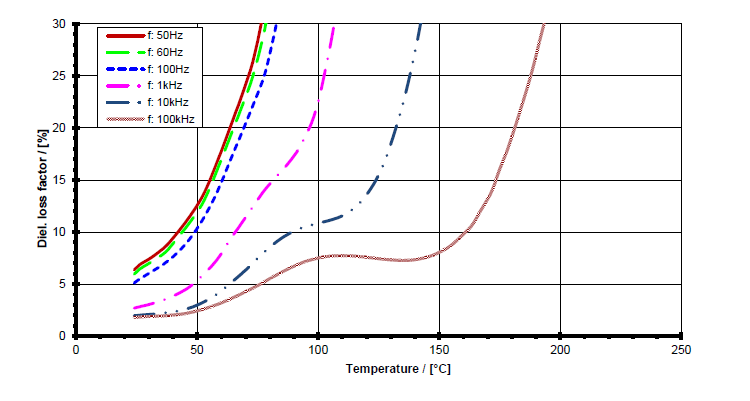

Dielectric constant 4.9 - IEC 60250 at 50Hz, 25°C, cured 24 hours at 25 °C plus 6 hours at 60°C Dissipation factor (tan δ) 5.3 % ISO 60250 at 50Hz, 25°C, cured 24 hours at 25 °C plus 6 hours at 60°C Tracking resistance CTI, grade >600 - IEC 60112 at 25°C, cured 24 hours at 25 °C plus 6 hours at 60°C Volume resistivity 1 × 10¹⁶ Ω·cm IEC 60093 at 25°C, cured 24 hours at 25 °C plus 6 hours at 60°C Electrolytic corrosion A-1 grade IEC 60426 at 23°C, cured 24 hours at 25 °C plus 6 hours at 60°C

Figure 1. Dielectric constant as a function of temperature (IEC 60250)

Figure 2: Dielectric loss as a function of temperature (IEC 60250)

Figure 3: Thermal endurance profile (IEC 60216)

- Processing Methods

Casting / vacuum casting.

- Processing Data

Preparation

CW 1302 contains fillers, which tend to settle over time. It is therefore recommended to carefully homogenize the complete contents of the container before use. In the storage vessels of the production equipment, the pre-filled products should be stirred up from time to time to avoid sedimentation and irregular metering.

Mixing

The casting mix is best prepared by heating the resin up to 40 to 50 °C before stirring in the hardener. Brief degassing of the mix under 5 to 10 mbar vacuum improves the mixture homogeneity and enhances the dielectric properties of the castings.

Curing

To determine whether cross-linking has been carried to completion and the final properties are optimal, it is necessary to carry out relevant measurements on the actual object or to measure the glass transition temperature. Different gel and cure cycles in the customer’s manufacturing process could lead to a different degree of cross- linking and thus a different glass transition temperature.- Mixed Properties

Property ARALDITE® CW 1302 Resin / ARADUR® HY 1300 Hardener Test Method Mixed viscosity at 40 °C, mPas 3,450 – 3,550 Rheomat Gel time, minutes at 25 °C 79 - 81 Gelnorm Gel time, minutes at 40 °C 50 - 75 Gelnorm Gel time, minutes at 60 °C 25 - 35 ISO 9396 Pot life at 40 °C, minutes (Time to reach 15,000 mPas) 36 - 38 Rheomat - Processing Guidelines

ARALDITE® CW 1302 Resin contains fillers which tend to settle over time. It is therefore necessary to carefully homogenize the complete contents of the container before use. To prevent filler separation and inconsistent metering, the components should be gently stirred from time to time while they are present in the production equipment storage tanks.

Mixing

To facilitate stirring and handling, highly filled component should be heated to 40 - 50°C in their original container (e.g. overnight in an oven) before adding the hardener. After a thorough mixing, the mixed material should be degassed under a 5 - 10 mbar vacuum to yield quality casting.

Curing

In manufacturing environment, the uncured impregnated parts will pick up moisture. Therefore, it is critical to fully cure the parts right after the impregnation or immediately store the uncured impregnated parts in a moisture-controlled area. To determine whether cross-linking has been carried to completion and the final properties are optimal, it is necessary to carry out some relevant measurements on the actual part or to measure the glass transition temperature of the cured system. Different gel and cure cycles in the manufacturing process are likely to lead to a different degree of crosslinking, hence different glass transition temperatures. The suggested curing process is 24 hours at room temperature (about 25 °C) plus 6 hours at 60 °C to yield parts with low shrinkage and best surface aspect. The minimum curing condition can be 48 hours at 25 °C.

Safety & Health

- Safety Precautions

Huntsman Advanced Materials Americas LLC maintains up-to-date Safety Data Sheets (SDS) on all of its products. These sheets contain pertinent information that you may need to protect your employees and customers against any known health or safety hazards associated with our products. Users should review the latest MSDS to determine possible health hazards and appropriate precautions to implement prior to using this material.

Storage & Handling

- Storage Conditions

ARALDITE® CW 1302 Resin contains some curing catalyst and / or accelerator. It should preferably not be stored for long periods at temperatures exceeding 40°C nor should it be exposed to temperatures more than 100°C for more than 2 hours. Incorrect handling will result in an increase in viscosity and reduced performance properties of the cured system.

ARALDITE® CW 1302 Resin should be stored in a dry place, in their sealed original container, at temperatures between 2°C and 40°C (35.6°F and 104°F). Under these storage conditions the shelf life is 1.5 years (from date of manufacture). These products should not be exposed to direct sunlight.

ARADUR® HY 1300 Hardener contains some curing catalysts and / or accelerators. Storage at elevated temperatures (>80°C) for extended periods (e.g. >5 days) will result in an undesirable increase in viscosity and will negatively affect the reactivity of the mixed system. This hardener is sensitive to moisture. Partially used containers should be closed immediately after use. The use of a desiccant venting device is highly recommended unless the material is going to be used rapidly after opening.

ARADUR® HY 1300 Hardener should be stored in a dry place, in their sealed original container, at temperatures between 2°C and 40°C (35.6°F and 104°F). Under these storage conditions the shelf life is 3 years (from date of manufacture). These products should not be exposed to direct sunlight.

- Storage Information

Store the components in a dry place according to the storage conditions stated on the label in tightly sealed original containers. Under these conditions, the shelf life will correspond to the expiry date stated on the label. After this date, the product may be processed only after reanalysis. Partly emptied containers should be tightly closed immediately after use.

Other

- Application Information

Value Units Test Method / Conditions Mix Ratio 0.11 %(W) %(W) Hardener : Resin