Enhanced TDS

Identification & Functionality

- Chemical Family

- RTU Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Product Features

- Medium - long pot-life up to 40°C

- Good mechanical and electrical properties

- Very good crack resistance

Applications & Uses

- Composites Processing Methods

- Cure Method

- Product End Uses

- Applications

Coils, Inductivities, e.g. MRI gradient coils, Instrument Transformers

- System Preparation

General instructions for preparing liquid resin systems

The filled resin component should be stirred and homogenized in the original container before use.

In the storage vessels of the production equipment, the pre-filled products should be stirred up from time to time to avoid sedimentation and irregular metering.

Brief degassing of the components under 5-10 mbar vacuum improves the mixture

homogeneity and enhances impregnation capability and the electrical end mechanical properties of the cured resin.

The casting mix is best prepared by heating the resin up to 30-40°C before stirring in the hardener.

Due to the relative short pot life, batch mixer is not recommended, a static or dynamic mixing and dosing equipment should be used.

Properties

- Processing Viscosities

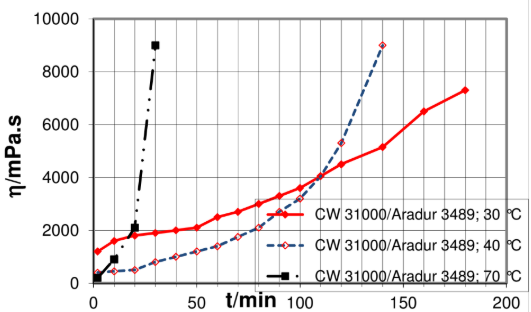

Viscosity vs. Time at 30°C, 40°C and 70 °C

Fig.4.1: Viscosity increase at 30, 40 and 70 °C

measurements with Rheostress 6000, PP20, 1 mm gap,10/sec

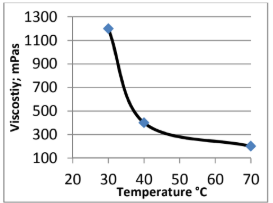

Fig.4.2: Initial viscosity in function of temperature

(measurements with Rheostress6000, D=10S-1)

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Mechanical & Physical Properties

Property

Test Method

Unit

Value

Tensile strength at 23 °C

ISO R527: 1999

N/mm²

65-70

Elongation at break

%

19-21

E modulus from tensile test

N/mm²

5800 - 6200

Tensile strength at -25 °C

ISO R527: 1993

N/mm²

89-92

Elongation at break

%

1.25

E modulus from tensile test

N/mm²

8058

Flexural strength

ISO 178: 2001

MPa

110-115

Surface strain

%

19-24

E modulus

MPa

6800 - 7200

Critical stress intensity factor (Kic)

PM 216-1989

MPa·m¹/²

1.9 - 2.4

Specific energy at break (Gic)

J/m²

510 - 540

Glass transition temperature (DSC)

ISO 11357-2: 1999

°C

72-76

Coefficient of linear thermal expansion

ISO 11359: 1999

ppm/K

59 (below Tg)

ppm/K

110 (above Tg)

Thermal conductivity similar to

ISO 8894-1

W/mK

0.61 - 0.63

Thermal ageing class (20000h)

IEC 60085

class

B

Water absorption (specimen: 50x50x4 mm)

ISO 62

% by wt.

10 days at 23°C

% by wt.

60 min at 100°C

% by wt.

10 h at 100°C

% by wt.

100 h at 100°C

Breakdown strength (1 mm thickness)

IEC 60243-1

kV/mm

50-55

Tracking resistance with test solution A

IEC 60112

CTI

> 600 < 1mm

Tracking resistance with test solution B

IEC 60112

CTI

350 M < 1mm

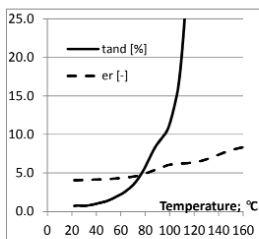

Fig.6.1: Loss factor (tan δ) and dielectric constant (εr) as a function of temperature

(measurement frequency: 50 Hz)

(IEC 250 / DIN 53483)

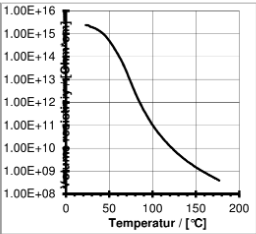

Fig.6.2: Volume resistivity (ρ) as a function of temperature

(measurement voltage: 1000 V)

(IEC 93 / DIN 53482)- Specific Instructions

The effective pot-life of the mix is about 4- 6 hours at temperatures at 25°C or below and 2 hours at 30 °C.

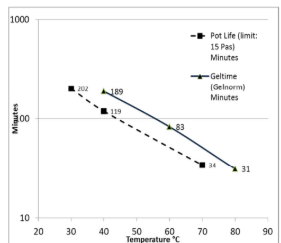

Viscosity increase and gel time at various temperatures,

Mould temperature

Conventional vacuum casting 30 - 50°C

Demoulding times (depending on mould temperature and casting volume)

Conventional vacuum casting 4 - 8 h

Cure conditions (minimal postcure)

Conventional Vacuum Casting 6 h at 50°C + 6h at 70°CTo determine whether crosslinking has been carried to completion and the final properties are optimal, it is necessary to carry out relevant measurements on the actual object or to measure the glass transition temperature. Different gelling and cure cycles in the manufacturing process could lead to a different crosslinking and glass transition temperature respectively.

- Gelation / Cure Time

Linear shrinkage after cure

12 h 30°C + 6 h 70°C: 0.15 %

Fig.4.4: Geltime and potlife measured in function of temperature

(Geltime measurement with Gelnorm Instrument)

Storage & Handling

- Storage Conditions

Store the components in a dry place in tightly sealed original containers. Under these conditions, the shelf life will correspond to the expiry date stated on the label. ARALDITE® 3489 is sensitive to humidity, partly emptied containers should be closed tightly immediately after use.

Other

- Application Information

Value Units Test Method / Conditions Mix Ratio 0.12 %(W) %(W) Hardener : Resin