Enhanced TDS

Identification & Functionality

- Chemical Family

- Fillers Included

- RTU Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Product Features

- Very good thermal shock resistance

- Very good thermal endurance

- Low viscosity

- Good storage stability

- Very good impregnation properties

Applications & Uses

- Composites Processing Methods

- Cure Method

- Product End Uses

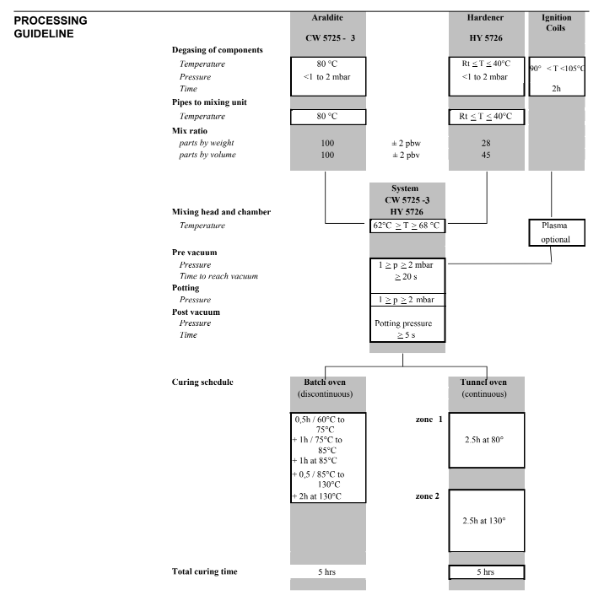

- System Preparation

Preparation

Araldite® CW 5725-3 Resin contains some fillers, which tend to settle over time. It is therefore recommended to carefully homogenize the container content before using. The material present in the production equipment storage tank should be stirred from time to time to prevent separation and inconsistent metering.Mixing

To facilitate stirring and removal, highly-filled components are heated to 60-80°C in the original container (e.g. overnight in an oven).

To prepare the casting mix the resin component should be homogenized in holding tank A at 70 - 80°C under a vacuum of 1-5 mbar, the hardener component in holding tank B at 30 - 40°C and a vacuum of 1 - 5 mbar. A metering unit should be used to feed the resin and hardener components to an impeller mixer.- Applications

- Automotive ignition coils

- Casting / vacuum casting

Technical Details & Test Data

- Mechanical & Physical Properties

Determined on standard test specimen at 23°C. Cured for 2.5h/90°C + 2.5h/130°C.

Color of casting

Visual

Black

Specific gravity

DIN 55990

g/cm2

1.73

Glass transition temperature

ISO 11357

°C

135- 150

Elastic modulus in flexion

ISO 178

MPa

7000

Max. bending stress

ISO 178

MPa

93-95

Surface strain (failure)

%

1.45-1.55

Double torsion test

PM 216-0/89

MPa m1/2

2.0 - 2.2

Double torsion test

PM 216-0/89

J/m2

475-700*

Coefficient of linear thermal expansion

DIN 53 752

ppm/K

35

Thermal conductivity

ISO 8894-1

W/mK

0.65

Hardness (4 mm plate)

DIN 53505

Shore D

90

Water absorption

ISO 62/80

10 days at 23°C

30 min at 100°CISO 62/80

% by wt.

0.08

0.05- Electrical Properties

Determined on standard test specimen at 23°C. Cured for 2.5h/90°C + 2.5h/130°C.

Dielectric strength (1 mm specimen)

IEC 60243-1

kV/mm

38

Volume resistivity, ρ ( 25°C)

IEC 60093

Ω cm

4.0 x1015

Tracking resistance

With test solution A

With test solution BIEC 60112

grade

CTI>600-0.1

CTI>600M-0.1Electrolytic corrosion

IEC 60426

grade

A-1

- Minimum Curing Time

2.5 hours at 90°C + 2.5 hours at 130°C

- Processing Guidelines

After curing, the components should be cooled down to min. 80°C for at least one hour in an enclosed area to exclude draughts and sudden temperature changes which might otherwise induce cracks in the cured casting.

Packaging & Availability

- Packaging Information

Araldite® CW 5725-3 Resin and Aradur® HY 5726 Hardener are supplied in 2,850 and 2,400 pounds totes respectively.

Storage & Handling

- Storage Conditions

When stored in a dry place in their original sealed containers at a temperature within 2°C and 40°C (35.6°F and 104°F), Araldite® CW 5725-3 Resin and Aradur® HY 5726 Hardener have a 12 months shelf-life from date of manufacture. The product should not be exposed to direct sunlight.

Other

- Application Information

Value Units Test Method / Conditions Mix Ratio 0.28 %(W) %(W) Hardener : Resin