Enhanced TDS

Identification & Functionality

- Chemical Family

- RTU Product Type

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Ready-to-Use Product Features

- Key Properties

- High impact strength and shear strength

- Outstanding arc and tracking resistance

- Thermal class F according IEC 60085

- Good thermal aging resistance in conjunction with glass cloth and mica paper

Applications & Uses

- Composites Processing Methods

- Cure Method

- Product End Uses

- Processing Information

System Preparation

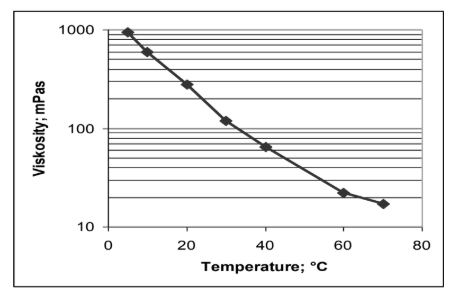

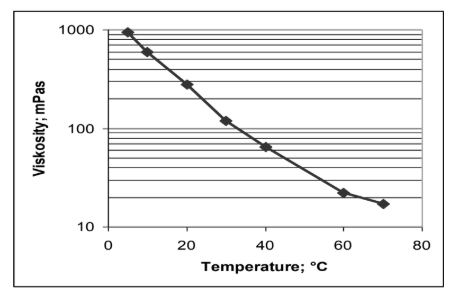

- Processing details depend very much on the conductor or machine type, on customer’s defined parameters and type of insulating tapes or fibers used. Generally the VPI system is used in impregnation vessels up to 30 tons where the conductor, rotor or stator is impregnated at elevated temperatures. Goods usually are prewarmed (30-50°C; also under vacuum) in order to remove moisture and to reduce viscosity during impregnation.

- After impregnation the VPI bath should be pumped into storage tanks and cooled down to 5 to 10°C and should be stored in dry conditions in order to obtain a long bath life. Actual bath life depends on additional parameters, e.g. impregnation temperature and duration of impregnation, impurities in the bath, wash-out of catalyst from mica tapes into the unaccelerated resin system, replenishment rate, moisture exposure etc. The viscosity of the bath should be checked periodically in order to maintain a suitable viscosity for

- impregnation.

- Impregnated, yet uncured parts in unconditioned atmosphere may pick up moisture. Therefore curing directly after impregnation or storage in a moisture controlled area is recommended. Generally machine parts are rotated when removed from the bath and during the first part of curing in order to avoid drip off.

- Replenishment of the batch depends on actual processing parameters and conditions and has to be evaluated at the customer site.

- On single coils and Roebel-bars the mica insulation is normally covered with a tight glass tape to prevent drainage of the impregnation resin.

Specific Instructions- To determine whether crosslinking has been carried to completion and the final properties are optimal, it is necessary to carry out relevant measurements on the actual object or to measure the glass transition temperature. Different gelling and cure cycles in the manufacturing process could lead to a different crosslinking and glass transition temperature respectively.

Properties

- Physical Form

- Resistance To Solvents

Solvent Result Acetone no change Benzene no change Hexane no change Methanol no change Carbon disulfide no change According to VDE 0170/0171/2.61 § 7a, immersion resin mixes for explosion-proof electrical equipment, protection (Ex)e, must be tested for resistance to solvent vapors. The solvents prescribed are acetone, benzene, hexane, methanol, and carbon disulfide with a purity of at least DAB 6.

Technical Details & Test Data

- Processing Methods

Vacuum Pressure Impregnation (VPI - process) for the impregnation of single conductors and for full-bath impregnation

- Cured Properties

Fig.1: :Viscosity of the impregnation mixture as a function of temperature

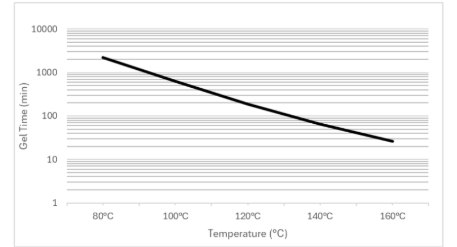

Fig.2: Geltime measured as a function of temperature

(measurements with Gelnorm Instrument /DIN 16945/ 6.3.1)

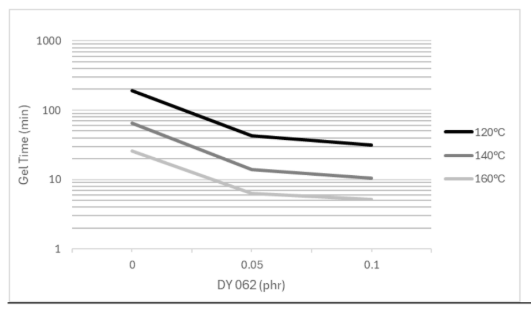

Fig.3: Addition of accelerator DY 062 for increased reactivity

(measurements with Gelnorm Instrument /DIN 16945/ 6.3.1)Property Test Method Unit Value Test Condition Tensile Strength ISO 527 MPa 75 - 85 Cured for 4h at 140°C

Elongation at Break ISO 527 % 0.90 - 1.10 Cured for 4h at 140°C

E Modulus from Tensile Test ISO 527 MPa 10,000 - 11,000 Cured for 4h at 140°C

Flexural Strength ISO 178 MPa 120 - 130 Cured for 4h at 140°C

Surface Strain ISO 178 % 1.20 - 1.40 Cured for 4h at 140°C

E Modulus from Flexural Test ISO 178 MPa 11,000 - 12,000 Cured for 4h at 140°C

Double Torsion Test (Critical stress intensity factor K1C) CG 216-0/89 MPa·m½ 3.10 - 3.70 Cured for 4h at 140°C

Double Torsion Test (Specific energy at break G1C) CG 216-0/89 J/m² 400 - 460 Cured for 4h at 140°C

Impact Strength ISO 179 kJ/m² 10 - 12 Cured for 4h at 140°C

Thermal Conductivity Similar To ISO 8894-1 W/m*K 1.02 - 1.04 Cured for 4h at 140°C

Coefficient of Linear Thermal Expansion ISO 11359-2 K⁻¹ 33 - 37*10⁻⁶ Cured for 4h at 140°C

Glass Transition Temperature (DSC) ISO 11357-2 °C 50 - 60 Cured for 4h at 140°C

Water Absorption (10 days at 23°C) ISO 62 % by wt. 0.15 - 0.22 Cured for 4h at 140°C

Water Absorption (60 min at 100°C) ISO 62 % by wt. 0.20 - 0.30 Cured for 4h at 140°C

Density ISO 1183 g/cm³ 1.83 - 1.86 Cured for 4h at 140°C

Dielectric Strength (1 min value, measured with 2mm sheet) IEC 60243-1 kV 57 - 83 Cured for 4h at 140°C

Dielectric Strength (after 96h / 20°C and 92% r.h.) IEC 60243-1 kV 38 - 50 Cured for 4h at 140°C

Dielectric Strength (at 150°C) IEC 60243-1 kV 39 - 52 Cured for 4h at 140°C

Volume Resistivity after Exposure to Water (Initial value) IEC 600093 Ω·cm ca. 10¹⁶ Cured for 4h at 140°C

Volume Resistivity after Exposure to Water (after 24h) IEC 600093 Ω·cm ca. 10¹⁵ Cured for 4h at 140°C

Volume Resistivity after Exposure to Water (after 48h) IEC 600093 Ω·cm ca. 10¹⁵ Cured for 4h at 140°C

Volume Resistivity after Exposure to Water (after 96h) IEC 600093 Ω·cm ca. 10¹⁵ Cured for 4h at 140°C

Volume Resistivity after Exposure to Water (after 240h) IEC 600093 Ω·cm ca. 10¹⁴ Cured for 4h at 140°C

Dielectric Loss Factor tan δ (at 23°C) IEC 60250 % 0.4 - 0.5 Cured for 4h at 140°C

Dielectric Loss Factor tan δ (at 60°C) IEC 60250 % 0.3 - 0.4 Cured for 4h at 140°C

Dielectric Loss Factor tan δ (at 80°C) IEC 60250 % 0.5 - 0.6 Cured for 4h at 140°C

Dielectric Loss Factor tan δ (at 100°C) IEC 60250 % ca. 3 Cured for 4h at 140°C

Dielectric Constant εr (at 23°C) IEC 60250 - 3.5 - 3.8 Cured for 4h at 140°C

Dielectric Constant εr (at 100°C) IEC 60250 - 3.8 - 4.0 Cured for 4h at 140°C

Tracking Resistance IEC 60112 grade KA 3c Cured for 4h at 140°C

Tracking Resistance IEC 60112 CTI >600 Cured for 4h at 140°C

Arc Resistance IEC 61621 s 180 - 190 Cured for 4h at 140°C

Electrolytic Corrosion IEC 60426 grade A-1 Cured for 4h at 140°C

Lapshear strength as a function of temperature

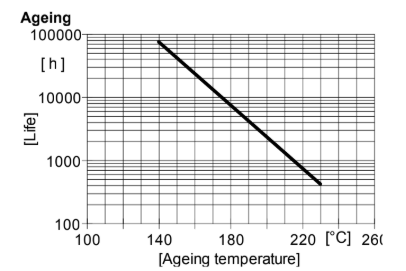

Ageing diagramm for 3% weight loss according IEC 60216

Storage & Handling

- Storage Conditions

Store the components in a dry place in tightly sealed original containers. Under these conditions, the shelf life will correspond to the expiry date stated on the label. Partly emptied containers should be tightly closed immediately after use.

Other

- Application Information

Value Units Test Method / Conditions Mix Ratio 1.0 %(W) %(W) Hardener : Resin