Enhanced TDS

Identification & Functionality

- Chemical Family

- RTU Product Type

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Ready-to-Use Product Features

- Key Properties

- Flame retardant

- Good aging resistance

- Good mechanical and electrical end properties

- High thermal endurance properties

- Suited for class F applications

Applications & Uses

- Composites Processing Methods

- Cure Method

- Product End Uses

- Filament Winding

Fiberglass direct rovings are immersed in a resin bath where they are coated with resin system. The impregnated tows are then literally wound around a mandrel (mold core) in a controlled pattern to form the shape of the part. After winding, the resin is then cured, typically using heat.

To achieve best mechanical and dielectric performance and good wetting, predrying of fibers is advised.

For good wetting of fibers and reproducable quality results it is recommended to warm up the impregnation batch to 30 - 40°C.

Temperature of the mandrel should be 60 - 90°C, preferred 70 - 80°C. With this setup gelation should occure from inner layers to outside layers, a good de-air will be achieved and

shrinkage minimized.

Resin is optimized for easy degassing.

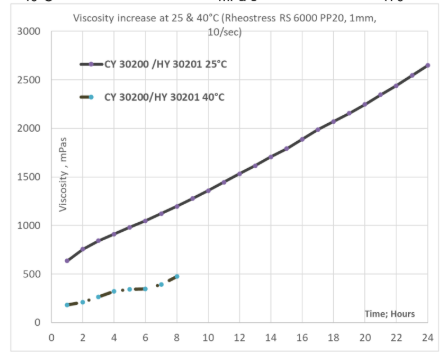

Usuable potlife of the mixed resin is > 1 shift (8 h) at 25°C and 40°C.

After impregnation and winding curing of the part should start as fast as possible, as the hardener in the reactive mixture is sensitive versus moisture.

Cure: 4 h 80 °C + 8 h 140 °C (standard lab condition)

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Mechanical, Physical and Electrical Properties

Mechanical, Physical and Properties

Property Value Unit Test Method At Condition Color RAL 8017 - - - Glass Transition Temperature 110-115 °C DSC, Mettler TA 4000 - Tensile Strength 88-95 N/mm² ISO 527 at 25°C Max. Tensile Stress 140-150 N/mm² ISO 527 at 25°C Elongation at Break 5-6 % ISO 527 at 25°C Elastic Modulus from Tensile Test 3000-3400 MPa ISO 527 at 25°C Flexural Strength 140-150 N/mm² ISO 178 at 25°C Elongation at Break (Flexural Strength) 6.5-7.3 % ISO 178 at 25°C Bend Notch Test - - ISO 178 - Critical Stress Intensity Factor (KIc) 0.7-0.75 MPa.m1/2 ISO 178 at 25°C Specific Energy at Break (GIc) 160-180 J/m² ISO 178 at 25°C Flammability >30 % ISO 60062 at 23°C Water Absorption 0.12 % ISO 62 at 23°C Water Absorption (at 100°C) 0.23 % ISO 62 at 100°C Coefficient of Linear Thermal Expansion 50-60 ppm/K ISO 11359: 1999 below Tg Electrical Properties

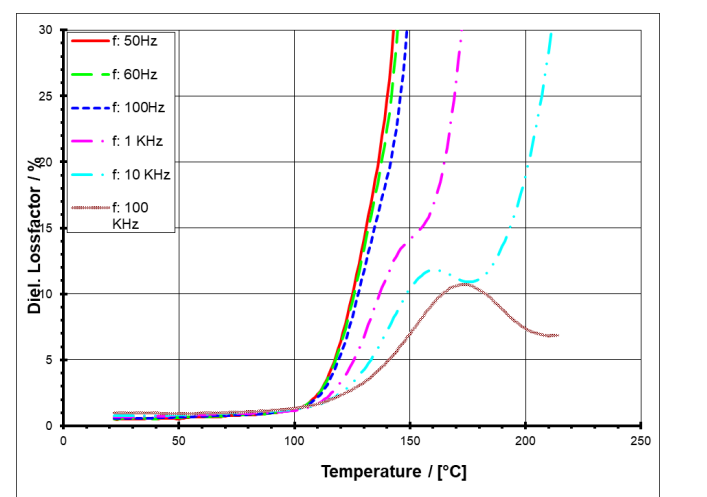

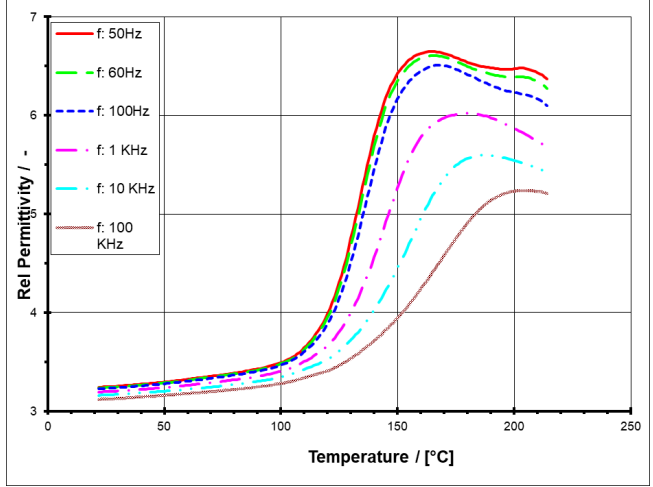

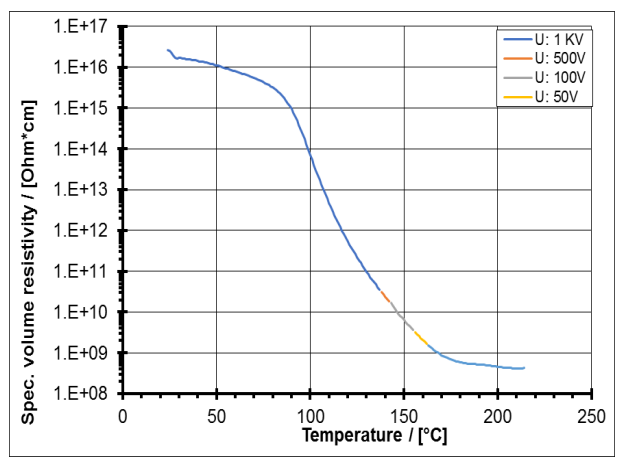

Property Value Unit Test Method At Condition Dielectric Constant (50 Hz) 3.2 % DIN 53483 at 23°C Dissipation Factor tan δ (50 Hz) 0.5 % DIN 53483 at 23°C Volume Resistivity (ρ) 2.60E+16 Ω·cm DIN 53482 at 23°C Electrolytic Corrosion A-1 grade DIN 53482 Tracking Resistance, Solution A CTI > 600 <1mm

IEC 60112 Tracking Resistance, Solution B CTI > 600M <1mm

IEC 60112 Electric Strength 28 - 30 kV/mm IEC 60243-1 at 23°C for 20 s

- Processing Information

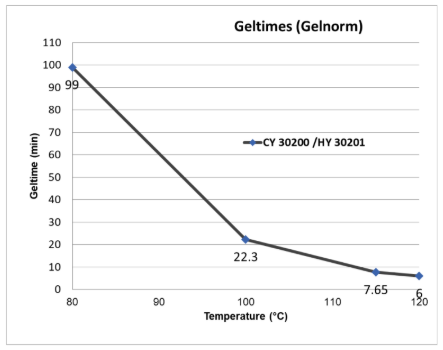

Processing Data

Storage & Handling

- Storage Conditions

The components have to be stored in tightly sealed and dry original containers according to the storage conditions on the product label. Under these conditions, the shelf life will correspond to the expiry date stated on the label. Partly emptied containers should be tightly closed immediately after use.

Other

- Application Information

Value Units Test Method / Conditions Mix Ratio 0.8 %(W) %(W) Hardener : Resin