Enhanced TDS

Identification & Functionality

- Chemical Family

- Fillers Included

- RTU Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Features and Benefits

- Liquid, latent, hot-curing casting resin system based on Bisphenol A/F

- High filler content possible due to low initial mix viscosity

- Long pot-life up to 70°C, short gel time at higher temperature

- Excellent mechanical and electrical properties

- Excellent crack resistance

- Very high thermal endurance properties (Class H according IEC 60085)

Applications & Uses

- Composites Processing Methods

- Cure Method

- Product End Uses

- Application Information

- Instrument transformer

- Dry type distribution transformer

- Insulating parts for medium and high-voltage application

- Conventional gravity casting process under vacuum

- Processing Information

The effective pot-life of the mix is about 2 days at temperatures below 25°C. Conventional batch mixers should be cleaned once a week or at the end of work. For longer work interruptions, the pipes of the mixing and metering installations have to be cooled and cleaned with the resin component to prevent sedimentation and/or undesired viscosity increase. Interruptions over a weekend (approx. 48h) without cleaning are possible if the pipes are cooled at temperatures below 18°C.

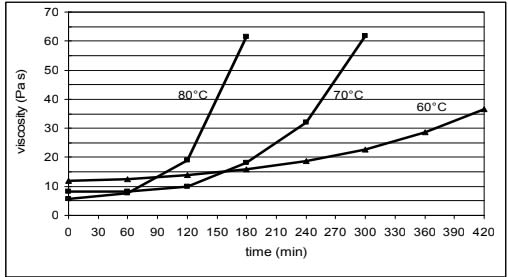

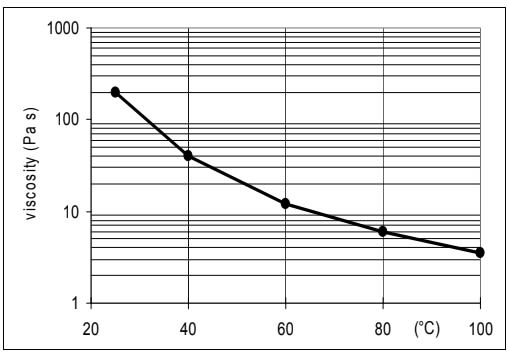

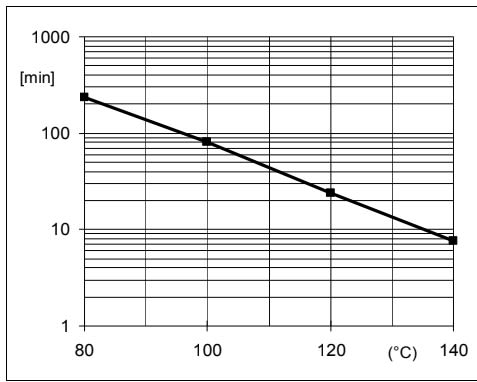

Viscosity increase and gel time at various temperatures, refer to Figure 1 and Figure 3.

Figure 1: Viscosity increase at 60°C and 80°C (measured with Rheomat 300 MS DIN 125 D – 10s⁻¹)

Figure 2: Initial viscosity as a function of temperature (measured with Rheomat 300 MS DIN 125 D – 10s⁻¹)

Figure 3: Gel time as a function of temperature (measured with Gelnorm Instrument ISO 93396)

Molding temperature:

Conventional vacuum casting: 80°C - 100°C

De-molding time (depending on molding temperature and casting volume):

Conventional vacuum casting: 8 hours to 20 hours

Cure condition:

Conventional vacuum casting for large casting parts:

12 hr 80°C and 3 hr 90°C and 3 hr 100°C and 4hr 110°C and 8 hr 120°CTo determine whether the complete cross-linking and the ultimate properties have been achieved, it is necessary to carry out the relevant testing on the cured casting or to measure its the glass transition temperature. Different gelling and cure cycles in the manufacturing process may lead respectively to different degrees of cross-linking and glass transition temperatures.

Typical Cured Properties

Key Value Unit Test Method Condition Tensile strength 85 - 95 MPa (12,325 - 13,775 psi) ISO 527 Cured for 4h at 80°C + 10h at 140°C, Determined on standard test specimen at 23°C Elongation at break

1.3 - 1.5 % ISO 527 Cured for 4h at 80°C + 10h at 140°C, Determined on standard test specimen at 23°C E modulus from tensile test

11,500 - 13,000 MPa (1,667,500 - 1,885,000 psi) ISO 527 Cured for 4h at 80°C + 10h at 140°C, Determined on standard test specimen at 23°C Flexural strength at 23°C

140 - 150 MPa (20,300 - 21,750 psi) ISO 178 Cured for 4h at 80°C + 10h at 140°C, Determined on standard test specimen at 23°C Surface strain at 23°C

1.4 - 1.6 % ISO 178 Cured for 4h at 80°C + 10h at 140°C, Determined on standard test specimen at 23°C Critical stress intensity factor (K1c)

3.1 - 3.4 MPa·m¹/² CG 216-0/89 Cured for 4h at 80°C + 10h at 140°C, Determined on standard test specimen at 23°C Specific energy at break (G1c)

750 - 850 J/m² CG 216-0/89 Cured for 4h at 80°C + 10h at 140°C, Determined on standard test specimen at 23°C Glass transition temperature (DSC)

80 - 90 °C (176 - 194°F) ISO 11357-2 Cured for 4h at 80°C + 10h at 140°C, Determined on standard test specimen at 23°C Coefficient of linear thermal expansion (Mean value below Tg)

32 - 36 ppm/K ISO 11359-2 Cured for 4h at 80°C + 10h at 140°C, Determined on standard test specimen at 23°C Thermal conductivity

0.98 - 1.08 W/mK Similar to ISO 8894-1 Cured for 4h at 80°C + 10h at 140°C, Determined on standard test specimen at 23°C Flammability (4mm)

Grade HB N/A UL 94 Cured for 4h at 80°C + 10h at 140°C, Determined on standard test specimen at 23°C Thermal endurance profile (Temperature index, Flexural strength, Thermal ageing class)

200°C (392°F), Class H °C (°F), class UL 746 B, IEC 60085 Cured for 4h at 80°C + 10h at 140°C, Determined on standard test specimen at 23°C Water absorption (specimen: 50×50×4 mm) (10 days at 23°C)

0.10 - 0.15 % by wt ISO 62 Cured for 4h at 80°C + 10h at 140°C, Determined on standard test specimen at 23°C Water absorption (specimen: 50×50×4 mm) (60 min at 100°C)

0.10 - 0.15 % by wt ISO 62 Cured for 4h at 80°C + 10h at 140°C, Determined on standard test specimen at 23°C Decomposition temperature (TGA)

≥ 350 °C (≥ 662°F) DTA Cured for 4h at 80°C + 10h at 140°C, Determined on standard test specimen at 23°C Density (Filler load: 66% by wt.)

1.90 - 1.96 g/cm³ ISO 1183 Cured for 4h at 80°C + 10h at 140°C, Determined on standard test specimen at 23°C Breakdown strength (3mm plates) (IEC 60243-1)

22 - 26 kV/mm IEC 60243-1 Cured for 4h at 80°C + 10h at 140°C, Determined on standard test specimen at 23°C Diffusion breakdown strength (DIN VDE 0441-1)

HD 2 Class DIN VDE 0441-1 Cured for 4h at 80°C + 10h at 140°C, Determined on standard test specimen at 23°C Temperature of specimen after test

< 23 °C N/A Cured for 4h at 80°C + 10h at 140°C, Determined on standard test specimen at 23°C HV arc resistance (IEC 61621)

183 - 196 sec IEC 61621 Cured for 4h at 80°C + 10h at 140°C, Determined on standard test specimen at 23°C Tracking resistance (with solution A)

CTI > 600 - 0.0 s IEC 60112 Cured for 4h at 80°C + 10h at 140°C, Determined on standard test specimen at 23°C

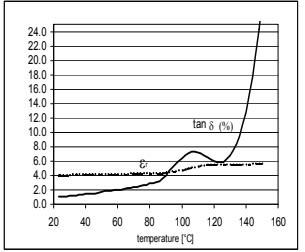

Figure 4: Loss factor (tanδ) and dielectric constant (εr) as a function of temperature (measured frequency: 50 Hz / IEC 60250/ DIN53483)

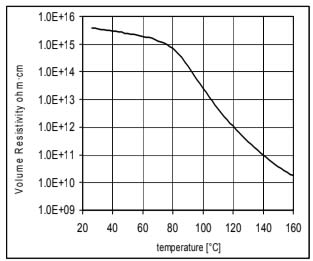

Figure 5: Volume resistivity (ρ) as a function of temperature (measured voltage: 1000 V / IEC 60093/ DIN 53482)

- System Preparation

General instructions for preparing liquid resin systems.

- Long pot life is desirable in the processing of any casting resin system. Mix all of the components together very thoroughly at room temperature or slightly above and under vacuum. Intensive wetting of the filler is extremely important. Proper mixing will result in:

- Better flow properties and reduced tendency to shrinkage

- Lower internal stresses and therefore improved mechanical properties on object

- Improved partial discharge behaviour in high voltage applications.

- For the mixing of medium to high viscous casting resin systems and for mixing at lower temperatures, we recommend special thin film degassing mixers that may produce additional self-heating of 10-15 K as a result of friction. For low viscous casting resin systems, conventional anchor mixers are usually sufficient.

- In larger plants, two pre-mixers are used to mix the individual components with the respective quantities of fillers and additives under vacuum. Metering pumps then feed these premixes to the final mixer or a continuous mixer. The individual premixes can be stored at elevated temperature (about 60°C) for up to about 1 week, de-pending on formulation. Intermittent agitation during storage is advisable to prevent filler sedimentation.

- Mixing time can vary from 0.5 to 3 hours, depending on mixing temperature, quantity, mixing equipment and the particular application. The required vacuum is 0.5 to 8 mbar. Degassing time is recommended at least 1 hour. The vapour pressure of the individual components should be taken into account.

- In the case of dielectrically highly stressed parts, we recommend checking the quality consistency and pre-drying of the filler. Their moisture content should be <0.2%.

Properties

- Physical Form

Packaging & Availability

- Packaging Information

System Component Araldite® CY 5948 Brown US Aradur® HY 925-1 US

Weight/Size 2500 pound tote 2500 pound tote

Storage & Handling

- Storage Conditions

- When stored in a dry place in their original sealed containers at a temperature within 2°C and 40°C (35.6°F and 104°F), Araldite® CY 5948 US Resin and Aradur® 925-1 US Hardener have a 3 year shelf-life from date of manufacture.

- Aradur® 925-1 US Hardener will readily react with moisture. Purging the container with dry nitrogen after each use is highly recommended. Storing Aradur® 925-1 US Hardener over extended periods of time at temperatures min. 45°C should be avoided as this may lead to undesirable viscosity increases and / or unacceptable cured casting properties.

Other

- Application Information

Value Units Test Method / Conditions Mix Ratio 3.5 %(W) %(W) Filler : Resin Mix Ratio 0.8 %(W) %(W) Hardener : Resin