Enhanced TDS

Identification & Functionality

- Chemical Family

- Fillers Included

- RTU Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Features and Benefits

- Excellent mechanical and electrical properties.

- Good thermal shock resistance

- Possibility of high filler content

Applications & Uses

- Composites Processing Methods

- Cure Method

- Product End Uses

- System Preparation

General instructions for preparing liquid resin systems.

Long pot life is desirable in the processing of any casting resin system. Mix all of the components together very thoroughly at room temperature or slightly above and under vacuum. Intensive wetting of the filler is extremely important. Proper mixing will result in:

- Better flow properties and reduced tendency to shrinkage

- Lower internal stresses and therefore improved mechanical properties on object

- Improved partial discharge behaviour in high voltage applications.

For the mixing of medium to high viscous casting resin systems and for mixing at lower temperatures, we recommend special thin film degassing mixers that may produce additional self-heating of 10-15°C as a result of friction. For low viscous casting resin systems, conventional anchor mixers are usually sufficient.

In larger plants, two pre-mixers are used to mix the individual components with the respective quantities of fillers and additives under vacuum. Metering pumps then feed these premixes to the final mixer or a continuous mixer. The individual premixes can be stored at elevated temperature (about 60°C) for up to about 1 week, de-pending on formulation. Intermittent agitation during storage is advisable to prevent filler sedimentation.

Mixing time can vary from 0.5 to 3 hours, depending on mixing temperature, quantity, mixing equipment and the particular application. The required vacuum is 0.5 to 8 mbar. Degassing time is recommended at least 1 hour. The vapour pressure of the individual components should be taken into account.

In the case of dielectrically highly stressed parts, we recommend checking the quality consistency and pre-drying of the filler. Their moisture content should be max. 0.2%.

- Application Information

Instrument transformers, dry type distribution transformer. Insulating parts medium and high voltage application.

Properties

- Physical Form

- Notes

End properties of this system have been tested with silica filler.

Technical Details & Test Data

- Processing Information

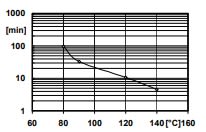

The effective pot-life of the mix is about 1 to 2 days at temperatures below 25°C. Conventional batch mixers should be cleaned once a week or at the end of work. For longer interruptions of work, the pipes of the mixing and metering installations have to be cooled and cleaned with the resin component to prevent sedimentation and/or undesired viscosity increase. Interruptions over a weekend (approx. 48h) without cleaning are possible if the pipes are cooled at temperatures below 18°C. For data on viscosity increase and gel time at various temperatures, refer to Figs: 4.1 and 4.4.

Mold temperature

APG process 120 - 160°C

Conventional vacuum casting 80 - 100°C

Demolding times (depending on reactivity, mold temperature and casting volume)

APG process 10 - 45 min

Conventional vacuum casting 1 - 6 h

Cure conditions

APG process (minimal postcure) 5h at 140°C

Conventional vacuum casting 4h at 80°C + 8h at 140°C

To determine whether crosslinking has been carried to completion and the final proper- ties are optimal, it is necessary to carry out relevant measurements on the actual object or to measure the glass transition temperature. Different gelling and cure cycles in the manufacturing process could lead to a different crosslinking and glass transition temperature respectively.Processing Viscosities

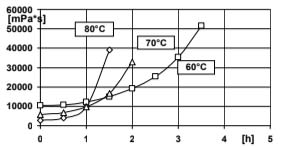

Fig.4.1: Viscosity increase at 60, 70 and 80°C (measurements with Rheomat 115) (measurements with Rheomat 115, D =10 s⁻¹)

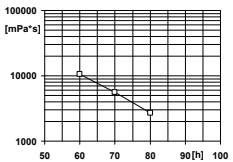

Fig.4.2: Initial viscosity as a function of temperature (measurements with Rheomat 115, D =10 s⁻¹)

Gelation and Cure Time

Fig.4.4: Geltime measured with Gelnorm Instrument as a function of temperature (ISO 9396)

Mechanical and Physical Properties

Key Value Unit Test Method Condition Tensile strength 75 - 85 MPa ISO 527 Cured for 6h at 130°C

Elongation at break 1.2 - 1.4 % ISO 527 Cured for 6h at 130°C

E modulus from tensile test 10,500 - 11,500 MPa ISO 527 Cured for 6h at 130°C

Flexural strength 135 - 145 MPa ISO 178 Cured for 6h at 130°C

Surface strain 1.3 - 1.5 % ISO 178 Cured for 6h at 130°C

E modulus from flexural test 11,000 - 12,000 MPa ISO 178 Cured for 6h at 130°C

Critical stress intensity factor (K1C) 2.5 - 2.7 MPa·m¹/² CG 216-0/89 Cured for 6h at 130°C

Specific energy at break (G1C) 500 - 600 J/m² CG 216-0/89 Cured for 6h at 130°C

Glass transition temperature (DSC) 75 - 85 °C ISO 11357-2 Cured for 6h at 130°C

Coefficient of linear thermal expansion (20-60°C) 37 - 41 x10⁻⁶ K⁻¹ ISO 11359-2 Cured for 6h at 130°C

Thermal conductivity 0.95 - 1.05 W/m·K Similar to ISO 8894-1 Cured for 6h at 130°C

Flammability (Thickness of specimen: 4 mm) HB UL 94 Cured for 6h at 130°C

Flammability (Thickness of specimen: 12 mm) HB UL 94 Cured for 6h at 130°C

Water absorption (10 days at 23°C) 0.10 - 0.15 % by wt ISO 62 Cured for 6h at 130°C

Water absorption (60 minutes at 100°C) 0.15 - 0.20 % by wt ISO 62 Cured for 6h at 130°C

Density (Filler load: 65% by weight) 1.70 - 1.80 g/cm³ ISO 1183 Cured for 6h at 130°C

Electrical Properties

Key Value Unit Test Method Condition Breakdown strength (IEC 60243-1) 18 - 22 kV/mm IEC 60243-1 Cured for 6h at 130°C

Breakdown strength (IEC 60243-1) 23 - 28 kV/mm IEC 60243-1 Cured for 6h at 130°C

Diffusion breakdown strength (DIN/VDE 0441/1) HD 2 Class DIN/VDE 0441/1 Cured for 6h at 130°C

Diffusion breakdown strength (DIN/VDE 0441/1) HD 2 Class DIN/VDE 0441/1 Cured for 6h at 130°C

Temperature of specimen after test < 23 °C Cured for 6h at 130°C

HV arc resistance (IEC 61621) 185 - 190 sec IEC 61621 Cured for 6h at 130°C

HV arc resistance (IEC 61621) 180 - 190 sec IEC 61621 Cured for 6h at 130°C

Tracking resistance (IEC 60112) CTI > 600 - 0.0 IEC 60112 Cured for 6h at 130°C

Tracking resistance (with test solution B) CTI > 600M - 0.0

IEC 60112 Cured for 6h at 130°C

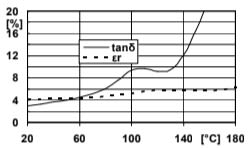

Fig.6.1: Loss factor (tan ) and dielectric constant ( r) as a function of temperature (measurement frequency: 50 Hz, IEC 60250)

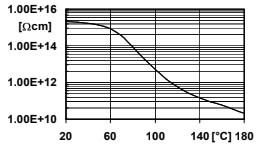

Fig.6.2: Volume resistivity ( ) as a function of temperature (measurement voltage: 1000 V, IEC 60093)

Safety & Health

- First Aid Information

- Contamination of the eyes by resin, hardener or casting mix should be treated immediately by flushing with clean, running water for 10 to 15 minutes. A doctor should then be consulted.

- Material smeared or splashed on the skin should be dabbed off, and the contaminated area then washed and treated with a cleansing cream (see above). A doctor should be consulted in the event of severe irritation or burns. Contaminated clothing should be changed immediately.

- Anyone taken ill after inhaling vapours should be moved out of doors immediately.

- Handling Precautions

Protective clothing

Yes Gloves Essential Arm protector Recommended when skin contact likely

Goggestery diasses

Yes Respirator/dust mask

Recommended Skin protection before starting work

Apply barrier cream to exposed skin

Skin protection after washing

Apply barrier or nourishing cream

Skin protection cleansing of contaminated skin

Dab off with absorbent paper, wash with warm water and alkali-free soap, then dry with disposable towels. Do not use solvents

Clean shop requirements

Cover workbenches, etc. with light coloured paper. Use disposable breakers, etc.

Disposal of spillage

Soak up with sawdust or cotton waste and deposit in plastic-lined bin

Ventilation: of workshop

Renew air 3 to 5 times an hour

Ventilation: of workplace

Exhaust fans. Operatives should avoid inhaling vapours.

Storage & Handling

- Storage Conditions

The components have to be stored in tightly sealed and dry original containers according to the storage conditions on the product label Under these conditions, the shelf life will correspond to the expiry date stated on the label. Product specific advise regarding storage can be found on product label. After this date, the product may be processed only following reanalysis. Partly emptied containers should be closed tightly immediately after use.

Other

- Application Information

Value Units Test Method / Conditions Mix Ratio 0.007 %(W) Accelerator : Resin Mix Ratio 0.8 %(W) Hardener : Resin